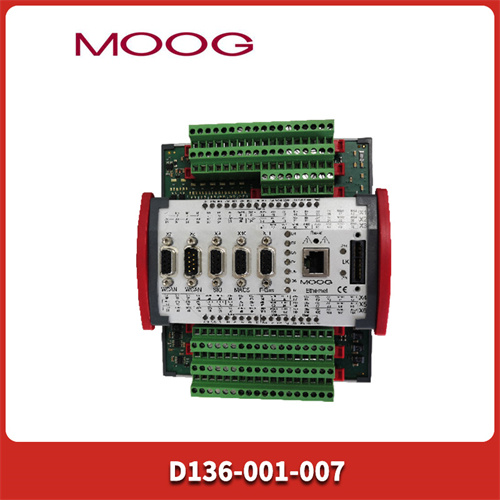

描述

MOOG D136-001-007是一款高性能伺服控制器,专为工业自动化和运动控制设计,具备多轴协调、高精度控制及灵活扩展特性。以下是其核心功能与技术参数的综合概述:

一、核心性能参数

处理器与计算能力

-基于PowerPC或32位RISC架构处理器,支持高速运算与实时控制。

-内存配置:4 MB RAM+4 MB Flash EEPROM,支持数据存储与固件升级。

控制精度与响应速度

-循环时间可低至400μs,满足高速运动控制需求。

-支持闭环轴控制(速度/位置/力),适用于伺服电机与液压作动器。

环境适应性

-工作温度范围:-20℃至+60℃(标准型号),防护等级IP20(DIN导轨安装)。

二、功能特点

多轴协调与扩展

-最多支持30轴同步控制,适用于复杂多轴联动场景(如机器人、数控机床)。

-模块化设计,可通过M3000扩展模块增加数字/模拟I/O或CAN总线接口。

现场总线与通信协议

-支持EtherCAT、PROFIBUS-DP、CANopen等协议,实现与PLC、上位机及第三方设备无缝对接。

-集成以太网接口,支持远程调试与数据传输。

软件与开发环境

-MACS(Moog Axis Control Software):基于IEC 61131-3标准的开发环境,支持梯形图、结构化文本等编程语言。

-集成PLC功能,可实现运动控制与逻辑处理的统一管理。

输入输出与传感器接口

-高分辨率模拟输入/输出(16位分辨率),支持±36 V过压保护。

-支持位置传感器(如SSI、增量编码器)及数字量输入/输出。

三、应用场景

工业自动化

-机器人、数控机床、包装机械等需要高精度运动控制的设备。

-航空航天领域(如导弹导向系统、飞行控制)。

能源与医疗

-风力发电机组控制、燃气轮机励磁系统。

-医疗设备(如手术机器人、精密检测仪器)。

特殊行业

-轮胎厂液压控制系统、玻璃制造自动化产线。

MOOG D136-001-007 is a high-performance servo controller designed for industrial automation and motion control,with multi-axis coordination,high-precision control and flexible expansion features.The following is a comprehensive overview of its core functions and technical parameters:

I.Core performance parameters

Processor and computing power

-Based on PowerPC or 32-bit RISC architecture processor,supports high-speed computing and real-time control.

-Memory configuration:4 MB RAM+4 MB Flash EEPROM,supports data storage and firmware upgrades.

Control accuracy and response speed

-Cycle time can be as low as 400μs,meeting the needs of high-speed motion control.

-Support closed-loop axis control(speed/position/force),suitable for servo motors and hydraulic actuators.

Environmental adaptability

-Operating temperature range:-20℃to+60℃(standard model),protection level IP20(DIN rail installation).

II.Functional features

Multi-axis coordination and expansion

-Supports up to 30-axis synchronous control,suitable for complex multi-axis linkage scenarios(such as robots,CNC machine tools).

-Modular design,digital/analog I/O or CAN bus interface can be added through M3000 expansion module.

Fieldbus and communication protocol

-Support EtherCAT,PROFIBUS-DP,CANopen and other protocols to achieve seamless connection with PLC,host computer and third-party equipment.

-Integrated Ethernet interface,support remote debugging and data transmission.

Software and development environment

-MACS(Moog Axis Control Software):A development environment based on IEC 61131-3 standard,supporting programming languagessuch as ladder diagram and structured text.

-Integrated PLC function,can achieve unified management of motion control and logic processing.

Input,output and sensor interface

-High-resolution analog input/output(16-bit resolution),support±36 V overvoltage protection.

-Support position sensors(such as SSI,incremental encoder)and digital input/output.

III.Application scenarios

Industrial automation

-Equipment that requires high-precision motion control,such as robots,CNC machine tools,packaging machinery,etc.

-Aerospace field(such as missile guidance system,flight control).

Energy and Medical

-Wind turbine control,gas turbine excitation system.

-Medical equipment(such as surgical robots,precision testing instruments).

Special Industries

-Tire factory hydraulic control system,glass manufacturing automation production line.