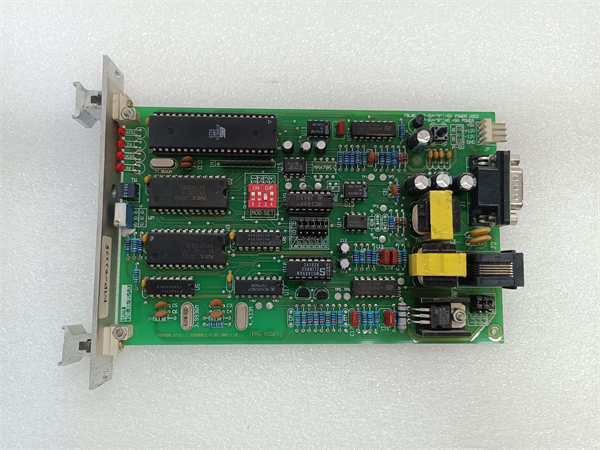

描述

Moore 16413-1-15是一款专为工业自动化设计的多功能I/O模块,适用于扩展PLC系统或构建分布式控制系统。以下是其核心功能与技术参数的综合概述:

一、产品定位

该模块通过标准化接口与主流PLC(如西门子、三菱、AB系列)无缝衔接,提供高可靠的数字量输入/输出(DI/DO)功能,广泛应用于工业控制、能源管理及智能制造领域。

二、技术参数

型号:Moore 16413-1-15

输入通道:16路数字输入(DI),支持干接点或电平信号(0-24V DC)

输出通道:8路数字输出(DO),继电器型,最大负载电流5A/路

隔离保护:输入/输出通道间隔离电压≥500V AC

通信接口:RS-485(Modbus RTU协议),支持远程配置与监控

工作温度:-40°C至+70°C(宽温设计)

三、核心功能

灵活扩展

通过DIN导轨安装,可扩展PLC的I/O点位,满足复杂系统对输入输出的需求。

智能诊断

内置自检功能,通过LED指示灯实时反馈通道状态(如故障、过载),简化维护流程。

协议兼容性

支持Modbus RTU协议,可与SCADA系统、HMI终端等设备实现数据交互。

四、性能特点

高可靠性

-采用工业级元器件,抗电磁干扰(EMI)等级符合IEC 61000标准。

-输入通道滤波设计,抑制噪声干扰。

宽电压适应

供电范围9-30V DC,支持直流或交流电源输入(需选配适配器)。

紧凑设计

尺寸小巧(120×85×55mm),适合空间受限的安装环境。

五、典型应用场景

工业控制系统

作为PLC扩展模块,采集现场设备状态(如开关、传感器信号)并控制执行机构(电磁阀、指示灯)。

能源管理

监测配电柜开关状态,实现远程分合闸控制。

智能制造

集成于工业机器人系统,完成物料检测与机械臂动作控制。.

PRG-MODEM

PRG-MODEM

Moore 16413-1-15 is a multifunctional I/O module designed for industrial automation,suitable for expanding PLC systems or building distributed control systems.The following is a comprehensive overview of its core functions and technical parameters:

1.Product positioning

This module seamlessly connects with mainstream PLCs(such as Siemens,Mitsubishi,and AB series)through standardized interfaces,providing highly reliable digital input/output(DI/DO)functions,and is widely used in industrial control,energy management,and intelligent manufacturing.

2.Technical parameters

Model:Moore 16413-1-15

Input channels:16 digital inputs(DI),support dry contacts or level signals(0-24V DC)

Output channels:8 digital outputs(DO),relay type,maximum load current 5A/channel

Isolation protection:Isolation voltage between input/output channels≥500V AC

Communication interface:RS-485(Modbus RTU protocol),support remote configuration and monitoring

Operating temperature:-40°C to+70°C(wide temperature design)

3.Core functions

Flexible expansion

Through DIN rail installation,the I/O points of the PLC can be expanded to meet the input and output requirements of complex systems.

Intelligent diagnosis

Built-in self-test function,real-time feedback of channel status(such as fault,overload)through LED indicators,simplifying the maintenance process.

Protocol compatibility

Supports Modbus RTU protocol,and can realize data interaction with SCADA systems,HMI terminals and other devices.

4.Performance characteristics

High reliability

-Industrial-grade components are used,and the anti-electromagnetic interference(EMI)level complies with the IEC 61000 standard.

-Input channel filtering design suppresses noise interference.

Wide voltage adaptation

Power supply range 9-30V DC,supports DC or AC power input(adapter required).

Compact design

Small size(120×85×55mm),suitable for installation environments with limited space.

5.Typical application scenarios

Industrial control system

As a PLC expansion module,it collects field equipment status(such as switches,sensor signals)and controls actuators(solenoid valves,indicator lights).

Energy management

Monitor the switch status of the distribution cabinet to achieve remote opening and closing control.

Intelligent manufacturing

Integrated in the industrial robot system to complete material detection and robot arm motion control.