描述

MTL 8502-B1-DP(通常列为8502-BI-DP)是由MTL(现为伊顿旗下公司)生产的总线接口模块(BIM)。它是工业自动化系统中的关键组件,专门用于弥合MTL 8000系列I/O模块与PROFIBUS-DP主控制器之间的通信差距。

主要产品详情和功能

总线接口模块(BIM):其主要作用是充当通信链路。它从连接的MTL 8000系列I/O模块(用于收集现场设备信号)收集数据,并根据PROFIBUS-DP主控制器的请求将这些数据提供给主控制器。反过来,它将主控制器的控制命令发送到I/O模块。

PROFIBUS-DP协议:该模块严格遵循PROFIBUS-DP(分散式外设)协议,该协议是自动化领域广泛使用的快速、确定性通信现场总线标准。它作为PROFIBUS从站运行。

高速数据传输:它支持各种数据传输速度,包括高达6 Mbaud(或6 Mbit/s,一些资料提到高达12 Mbps),从而能够快速响应控制过程中不断变化的条件。

I/O模块支持:8502-BI-DP最多可连接并支持24个MTL 8000系列I/O模块。这使得大量现场设备(传感器、执行器等)可以通过单个BIM集成到PROFIBUS网络中。

HART通信:其主要特性是支持HART(高速可寻址远程传感器)通信。这使得BIM能够将HART过程和状态变量从智能现场设备(通过MTL 8000 I/O模块连接)通过PROFIBUS-DP网络传输到主机,从而实现高级诊断和资产管理。

强大的诊断功能:除了标准PROFIBUS状态信息外,它还提供扩展诊断功能。这些诊断功能可让您深入了解BIM本身的状态、所连接I/O模块的健康状况以及各个I/O通道的状态(例如,检测高/低报警、开路或线路故障)。

隔离保护:该模块在LAN、Railbus(连接到I/O模块的背板)和电源之间提供电气隔离(通常为500V)。这种隔离可保护设备免受接地环路、电涌和共模噪声的影响,从而提高系统的可靠性和安全性。

配置灵活性:它可通过本地端口或通过PROFIBUS主机使用PROFIBUS配置器中的GSD文件(通用站描述文件)进行软件配置。这允许轻松地按模块进行参数配置。

故障安全设计:如果发生软件故障或通信丢失,该模块和相关的I/O模块将进入故障安全状态,防止操作失控并提高安全性。

热插拔:此功能简化了维护,因为通常可以在不中断整个网络运行的情况下更换故障模块。

安装:它安装在提供通信和电源连接的托架上。

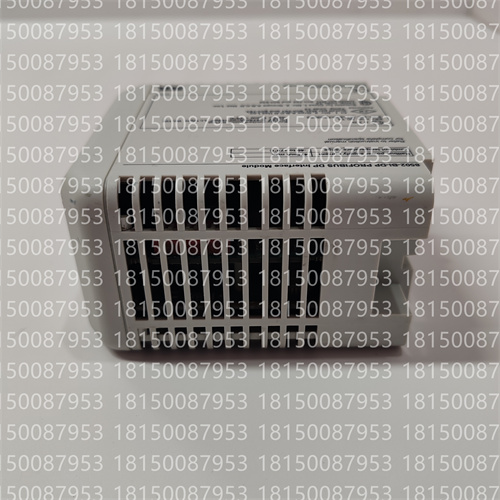

坚固耐用的结构:采用优质材料和制造技术,可适应恶劣的工业环境,符合IEC 61316等标准,通常具有IP20或更高的防护等级。

通用规格

制造商:MTL(伊顿)

产品类型:总线接口模块(BIM)

协议:PROFIBUS-DP(从站)

支持的I/O模块:最多24个MTL 8000系列I/O模块

数据传输速度:最高6 Mbaud(或6 Mbps),部分来源显示最高可达12 Mbps

输入电压:24 V DC(由MTL 8000基座供电)

电流消耗:通常约为100 mA

工作温度:-20°C至+60°C(或-20°C至+70°C,取决于具体型号/文档)

存储温度:-40°C至+85°C

重量:约0.350 kg至0.450 kg

尺寸:通常约为120mm x 80mm x 45毫米(具体尺寸可能因具体来源而略有不同)。

认证:设计符合相关工业标准和电磁兼容性(EMC)要求。

典型应用

MTL 8502-B1-DP广泛应用于:

过程自动化系统:在石油天然气、化工、石化、发电、水/废水处理以及其他使用MTL 8000系列I/O将现场设备连接到中央PROFIBUS-DP控制系统的行业中。

工业控制系统(DCS/PLC):提供现场仪表与上位控制系统之间的通信。

数据采集系统:用于从分布式I/O采集实时过程数据。

危险区域应用:鉴于MTL在本质安全方面的专业知识,这些模块通常是危险分类场所系统的一部分,尽管BIM本身可能不是本质安全的,但连接到本质安全的I/O。

The MTL 8502-B1-DP(often listed as 8502-BI-DP)is a Bus Interface Module(BIM)manufactured by MTL,which is now part of Eaton.It’s a critical component in industrial automation systems,specifically designed to bridge the communication gap between MTL’s 8000 series I/O modules and a PROFIBUS-DP host controller.

Key Product Details and Functions

Bus Interface Module(BIM):Its primary role is to act as a communication link.It gathers data from the connected MTL 8000 series I/O modules(which collect signals from field devices)and makes this data available to a PROFIBUS-DP master controller upon request.Conversely,it sends control commands from the master to the I/O modules.

PROFIBUS-DP Protocol:The module strictly adheres to the PROFIBUS-DP(Decentralized Peripherals)protocol,which is a widely used fieldbus standard for fast and deterministic communication in automation.It operates as a PROFIBUS slave.

High-Speed Data Transfer:It supports various data transmission speeds,including up to 6 Mbaud(or 6 Mbit/s,and some sources mention up to 12 Mbps),enabling rapid response to changing conditions in the control process.

I/O Module Support:The 8502-BI-DP can connect to and support up to 24 MTL 8000 series I/O modules.This allows for a significant number of field devices(sensors,actuators,etc.)to be integrated into the PROFIBUS network through a single BIM.

HART Communication:A key feature is its support for HART(Highway Addressable Remote Transducer)communication.This allows the BIM to pass HART process and status variables from intelligent field devices(connected via MTL 8000 I/O modules)over the PROFIBUS-DP network to the host,enabling advanced diagnostics and asset management.

Robust Diagnostics:It offers extended diagnostics in addition to standard PROFIBUS status information.These diagnostics provide detailed insights into the status of the BIM itself,the health of the connected I/O modules,and the status of individual I/O channels(e.g.,detecting high/low alarms,open circuits,or line faults).

Isolation Protection:The module provides electrical isolation(typically 500V)between the LAN,Railbus(backplane connection to I/O modules),and power supply.This isolation protects devices from ground loops,electrical surges,and common-mode noise,enhancing system reliability and safety.

Configuration Flexibility:It is software configurable via the local port or through the PROFIBUS host using GSD files(General Station Description files)in a PROFIBUS configurator.This allows for easy parameterization on a”per module”basis.

Fail-Safe Design:In case of a software malfunction or communication loss,the module and associated I/O modules are designed to enter a failsafe state,preventing uncontrolled operation and enhancing safety.

Hot-Swappable:This feature simplifies maintenance,as a faulty module can often be replaced without interrupting the operation of the entire network.

Mounting:It mounts on a carrier that provides its communication and power links.

Rugged Construction:Built with high-quality materials and manufacturing technology to suit harsh industrial environments,conforming to standards like IEC 61316 and often having an IP20 or higher protection level.

General Specifications

Manufacturer:MTL(Eaton)

Product Type:Bus Interface Module(BIM)

Protocol:PROFIBUS-DP(Slave)

Supported I/O Modules:Up to 24 MTL 8000 series I/O modules

Data Transmission Speed:Up to 6 Mbaud(or 6 Mbps),some sources indicate up to 12 Mbps

Input Voltage:24 V DC(supplied from the MTL 8000 carrier)

Current Consumption:Typically around 100 mA

Operating Temperature:-20°C to+60°C(or-20°C to+70°C,depending on specific variant/documentation)

Storage Temperature:-40°C to+85°C

Weight:Approximately 0.350 kg to 0.450 kg

Dimensions:Typically around 120mm x 80mm x 45mm(dimensions may vary slightly by specific source).

Certifications:Designed to meet relevant industrial standards and EMC compliance.

Typical Applications

The MTL 8502-B1-DP is widely used in:

Process Automation Systems:In oil&gas,chemical,petrochemical,power generation,water/wastewater treatment,and other industries where MTL 8000 series I/O is used to connect field devices to a central PROFIBUS-DP control system.

Industrial Control Systems(DCS/PLC):Providing communication between field instruments and higher-level control systems.

Data Acquisition Systems:For collecting real-time process data from distributed I/O.

Hazardous Area Applications:Given MTL’s expertise in intrinsic safety,these modules are often part of systems used in hazardous classified locations,though the BIM itself might not be intrinsically safe but rather connected to intrinsically safe I/O.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101