描述

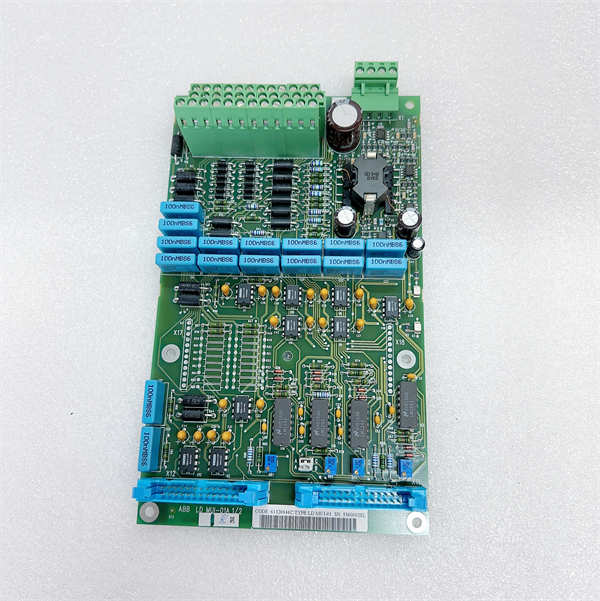

MULLER COAX MK32NC是一款工业级通信扩展模块,专为复杂自动化系统设计,具备多协议支持、高可靠性与灵活扩展能力。以下是其核心功能与技术特点的综合解析:

一、核心功能与定位

通信协议兼容性

支持Modbus TCP/RTU、Profinet、EtherNet/IP等主流工业协议,可无缝对接PLC、SCADA系统及第三方设备。

集成RS-485/RS-232串口与以太网接口,支持协议转换与数据中继。

端口扩展能力

提供2路独立以太网接口(支持10/100 Mbps),支持冗余配置以提升通信稳定性。

支持8路数字量输入/输出通道,可扩展至更多I/O模块。

工业级防护设计

防护等级IP20,适应工业环境灰尘与湿度。

工作温度范围-25°C至+70°C,抗振动与电磁干扰能力符合工业标准。

二、技术参数与性能

通信速率

以太网接口支持全双工通信,数据传输速率最高100 Mbps。

RS-485接口通信距离可达1.2 km(波特率9600bps)。

数据处理能力

实时数据过滤与校验功能,减少噪声干扰。

支持数据缓存与断点续传,避免通信中断导致的数据丢失。

安全特性

内置过压保护与浪涌抑制电路,防止瞬态电压损坏模块。

支持故障自检与报警功能,异常时触发继电器输出或通信中断信号。

三、应用场景

智能制造

用于机器人协作系统中传感器数据采集与指令下发。

集成于MES系统,实现设备状态远程监控与故障诊断。

能源与电力

部署于变电站自动化系统,传输断路器状态与保护装置信号。

支持光伏电站数据采集与逆变器通信管理。

交通与物流

应用于港口自动化装卸设备,协调多设备协同作业。

集成于智能仓储系统,实现AGV小车路径规划与指令传输。

LDMUI-001 61320946C

LDMUI-001 61320946C

MULLER COAX MK32NC is an industrial-grade communication expansion module designed for complex automation systems.It has multi-protocol support,high reliability and flexible expansion capabilities.The following is a comprehensive analysis of its core functions and technical features:

1.Core functions and positioning

Communication protocol compatibility

Supports mainstream industrial protocols such as Modbus TCP/RTU,Profinet,EtherNet/IP,and can seamlessly connect to PLC,SCADA systems and third-party devices.

Integrated RS-485/RS-232 serial port and Ethernet interface,support protocol conversion and data relay.

Port expansion capability

Provides 2 independent Ethernet interfaces(supports 10/100 Mbps)and supports redundant configuration to improve communication stability.

Supports 8 digital input/output channels,which can be expanded to more I/O modules.

Industrial-grade protection design

Protection level IP20,adapt to industrial environment dust and humidity.

Operating temperature range-25°C to+70°C,vibration and electromagnetic interference resistance meet industrial standards.

2.Technical parameters and performance

Communication rate

The Ethernet interface supports full-duplex communication with a data transmission rate of up to 100 Mbps.

The communication distance of the RS-485 interface can reach 1.2 km(baud rate 9600bps).

Data processing capability

Real-time data filtering and verification functions to reduce noise interference.

Supports data caching and breakpoint resumption to avoid data loss caused by communication interruption.

Safety features

Built-in overvoltage protection and surge suppression circuits to prevent transient voltage from damaging the module.

Supports fault self-detection and alarm functions,triggering relay output or communication interruption signals when abnormal.

3.Application scenarios

Intelligent manufacturing

Used for sensor data collection and command issuance in robot collaborative systems.

Integrated in the MES system to achieve remote monitoring of equipment status and fault diagnosis.

Energy and power

Deployed in the substation automation system to transmit circuit breaker status and protection device signals.

Supports photovoltaic power station data collection and inverter communication management.

Transportation and logistics

Applied to port automated loading and unloading equipment to coordinate multi-device collaborative operations.

Integrated into the intelligent warehousing system to realize AGV path planning and command transmission.