描述

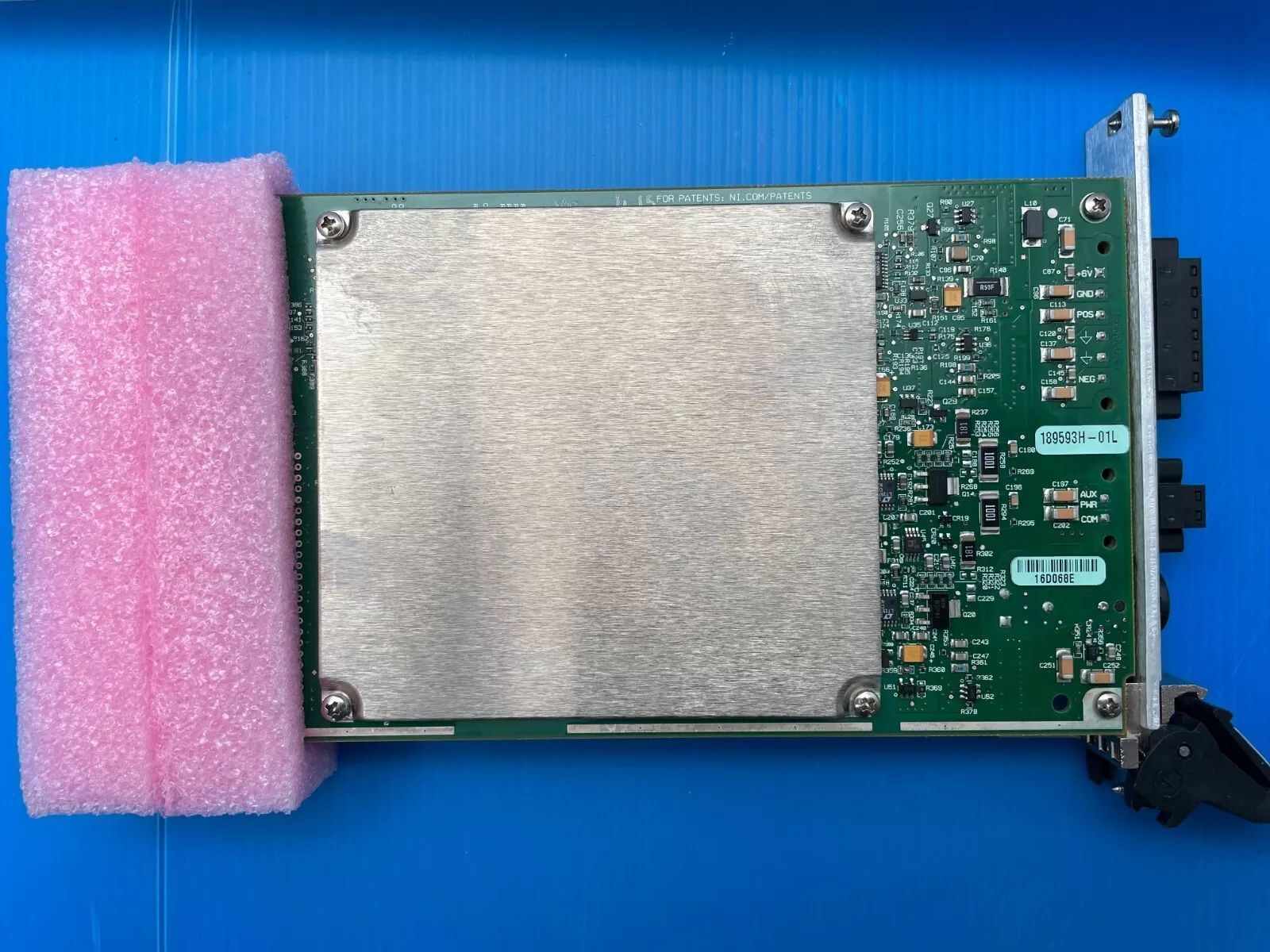

NI PXI-4110是美国国家仪器(NI)推出的高精度可编程直流电源模块,专为自动化测试系统设计,适用于航空航天、汽车电子、半导体测试等领域。其核心优势在于三路独立输出通道、高分辨率编程能力及灵活的组合模式,支持电压/电流精确控制与实时测量。

核心参数与性能

输出通道配置

-隔离通道:

-通道1:0至+20 V,最大电流1 A(需辅助电源时可达1 A);

-通道2:0至-20 V,最大电流1 A。

-非隔离通道:

-通道0:0至+6 V,固定电流1 A。

-组合能力:通道可并联或串联,扩展电压/电流范围(如±40 V或2 A输出)。

精度与分辨率

-电压编程:

-分辨率:+6 V通道0.12 mV,±20 V通道0.40 mV;

-准确度:±(0.05%+4 mV)(典型值)。

-电流编程:

-分辨率:1 A范围下0.02 mA;

-准确度:±(0.15%+4 mA)。

动态性能

-响应速度:支持快速电压/电流设定值切换(典型settling time<10 ms);

-保护功能:过压、过流自动关断,支持远程感应补偿线路损耗。

物理接口

-输出连接器:BNC接口(每通道独立隔离地);

-辅助电源输入:需外接11–15.5 V/≥60 W电源以实现全电流输出。

技术特点

混合架构设计

-线性+开关技术结合:采用线性输出确保低噪声,搭配FPGA控制预调整电路提升效率与动态响应。

智能化控制

-编程灵活性:支持电压设定、电流限值设定及实时回读功能(16位精度);

-远程管理:通过PXI总线实现多模块同步控制,适用于自动化测试流水线。

工业兼容性

-隔离保护:通道1/2支持60 VDC耐压(CAT I等级),降低共模干扰风险;

-环境适应性:工作温度范围0–55℃,温漂系数低至0.005%/°C。

典型应用场景

汽车电子测试

-电池模拟(动态电压脉冲加载);

-ECU供电稳定性验证(多通道联合输出)。

航空航天设备验证

-传感器供电与信号激励(高精度低噪声优势);

-机载电子设备环境应力测试(宽温区运行保障)。

半导体制造

-器件参数测试(电流限制保护防止过流损坏);

-多DUT并行测试(通道独立控制节省时间)。

NI PXI-4110 is a high-precision programmable DC power module launched by National Instruments(NI).It is specially designed for automated testing systems and is suitable for aerospace,automotive electronics,semiconductor testing and other fields.Its core advantages are three independent output channels,high-resolution programming capabilities and flexible combination modes,which support precise voltage/current control and real-time measurement.

Core parameters and performance

Output channel configuration

-Isolation channel:

-Channel 1:0 to+20 V,maximum current 1 A(up to 1 A when auxiliary power is required);

-Channel 2:0 to-20 V,maximum current 1 A.

-Non-isolated channel:

-Channel 0:0 to+6 V,fixed current 1 A.

-Combination capability:The channels can be connected in parallel or in series,extending the voltage/current range(such as±40 V or 2 A output).

Accuracy and resolution

-Voltage programming:

-Resolution:+6 V channel 0.12 mV,±20 V channel 0.40 mV;

-Accuracy:±(0.05%+4 mV)(typical).

-Current Programming:

-Resolution:0.02 mA in the range of 1 A;

-Accuracy:±(0.15%+4 mA).

Dynamic performance

-Response speed:Supports fast voltage/current setpoint switching(typical setting time<10 ms);

-Protection function:automatic shutdown of overvoltage and overcurrent,supporting remote sensing to compensate for line losses.

Physical interface

-Output connector:BNC interface(independently isolated ground for each channel);

-Auxiliary power input:An external 11–15.5 V/≥60 W power supply is required to achieve full current output.

Technical Features

Hybrid architecture design

-Combination of linear+switching technology:linear output is used to ensure low noise,and FPGA control pre-adjustment circuit improves efficiency and dynamic response.

Intelligent control

-Programming flexibility:Supports voltage setting,current limit setting and real-time readback functions(16-bit accuracy);

-Remote management:Multi-module synchronous control is realized through the PXI bus,suitable for automated test pipelines.

Industrial compatibility

-Isolation protection:Channel 1/2 supports 60 VDC voltage withstand voltage(CAT I level),reducing the risk of common mode interference;

-Environmental adaptability:Operating temperature range is 0–55℃,temperature drift coefficient is as low as 0.005%/°C.

Typical application scenarios

Automotive electronic testing

-Battery simulation(dynamic voltage pulse loading);

-ECU power supply stability verification(multi-channel joint output).

Aerospace Equipment Verification

-Sensor power supply and signal excitation(high accuracy and low noise advantages);

-Environmental stress test for airborne electronic equipment(wide temperature zone operation guarantee).

Semiconductor manufacturing

-Device parameter test(current limit protection to prevent overcurrent damage);

-Multi-DUT parallel testing(channel independent control saves time).