描述

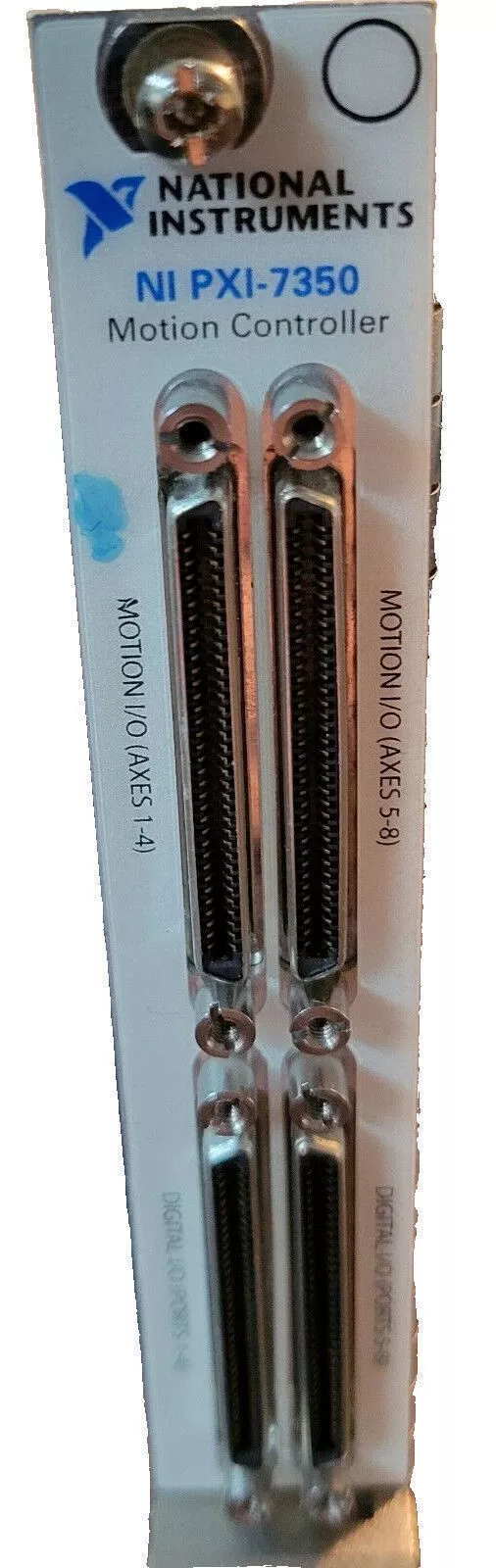

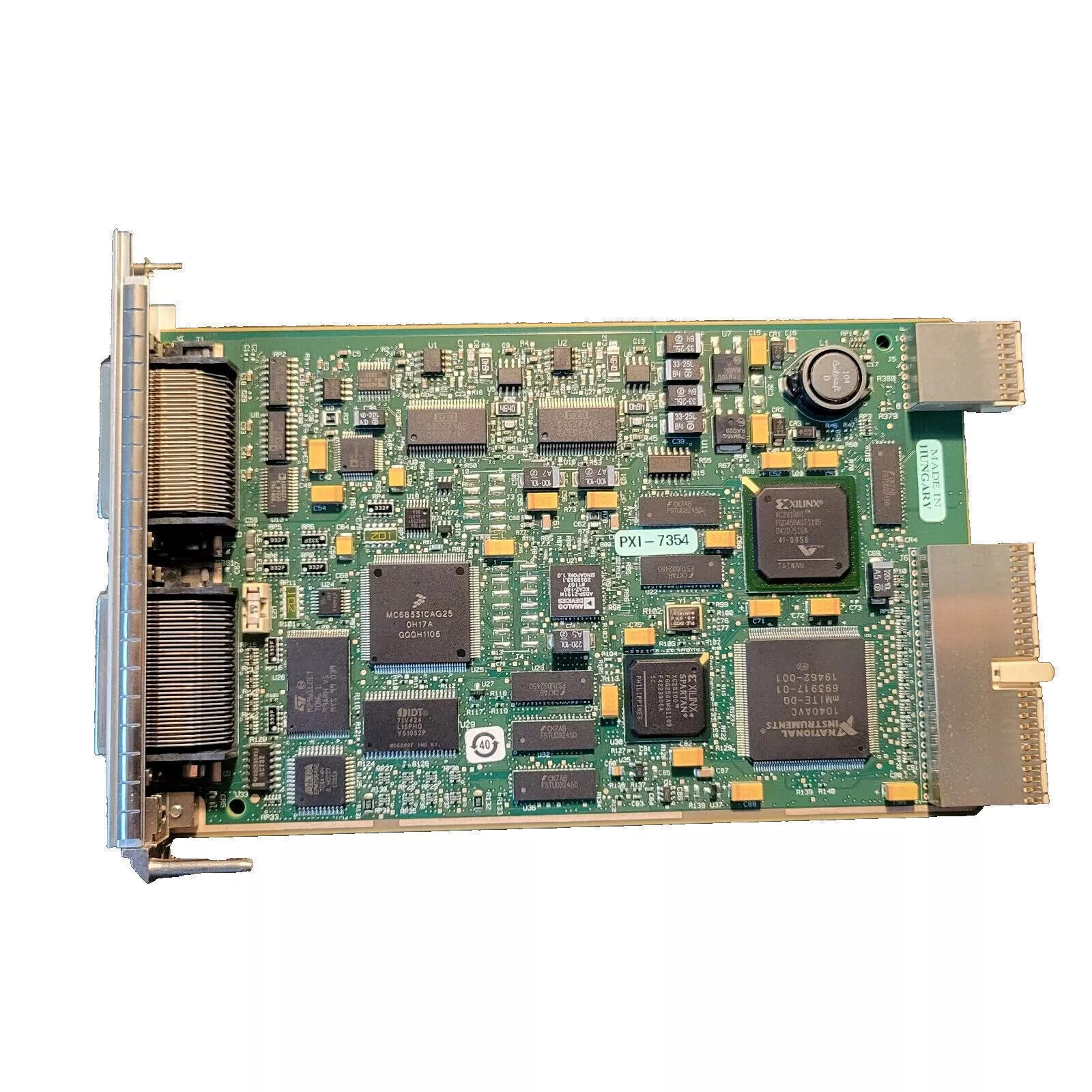

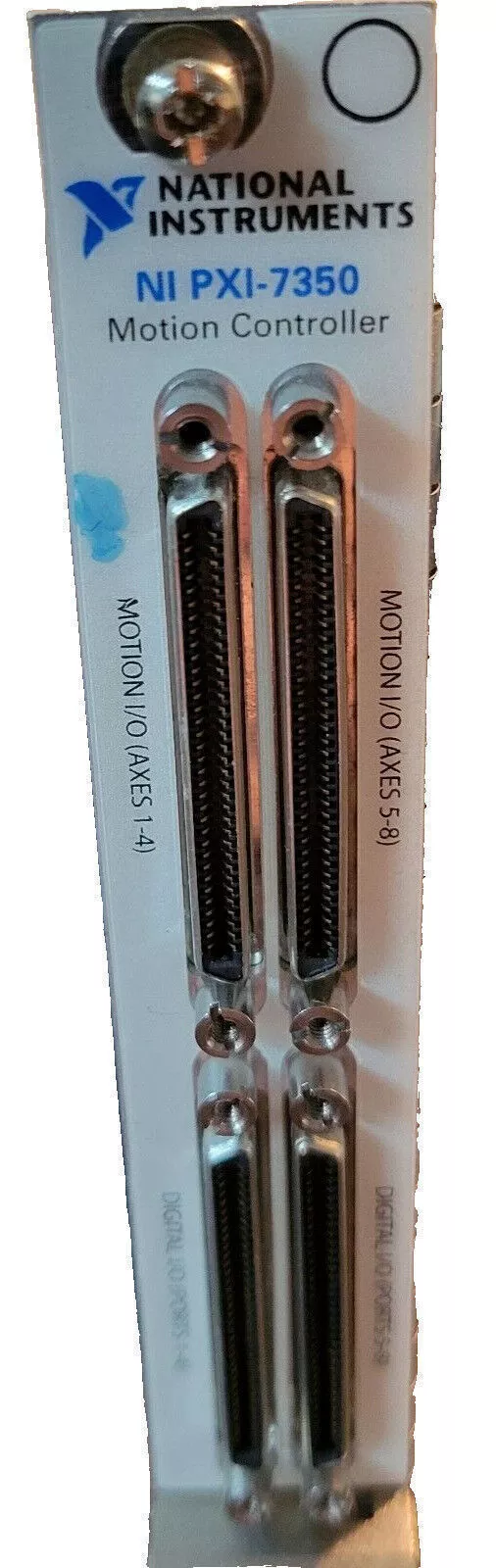

NI PXI-7350产品详情

产品概述

NI PXI-7350是National Instruments(NI)推出的一款高性能运动控制模块,专为PXI和PXI Express系统设计。它支持多轴同步控制(最高8轴),集成步进电机和伺服电机驱动功能,并配备高速编码器反馈接口,适用于精密自动化、机器人、CNC加工、半导体测试等需要高精度运动控制的应用场景。该模块通过NI-Motion软件驱动与LabVIEW、C/C++等开发环境无缝集成,可快速构建复杂的运动控制系统。

核心功能

多轴同步控制

支持2至8轴独立或协同运动,轴间同步精度可达微秒级,满足多轴联动需求(如机器人关节控制、XY平台定位)。

每轴独立配置运动参数(速度、加速度、减速度、位置等),支持梯形、S曲线、电子齿轮、凸轮等多种运动模式。

步进与伺服电机驱动

步进电机控制:支持全步、半步、微步(1/4至1/256细分),降低振动并提高分辨率。

伺服电机控制:集成PID闭环控制算法,支持编码器反馈(增量式/绝对式)和模拟扭矩控制,实现高精度定位。

电流调节:每轴可独立设置驱动电流(0.1 A至4 A连续可调),适配不同功率电机。

高速编码器反馈

每轴配备差分编码器输入接口(ABZ相),支持最高8 MHz编码器频率,实时监测电机位置和速度。

支持正交编码器、霍尔传感器、SSI(同步串行接口)等多种反馈类型,兼容主流电机品牌(如Maxon、Faulhaber、Yaskawa)。

实时运动监控与保护

提供限位开关、原点传感器、急停输入等安全接口,防止机械碰撞或过载。

实时监测电机状态(如电流、温度、编码器错误),并通过NI-DAQmx或NI-Motion API触发报警或保护动作。

灵活的触发与同步

支持软件触发、硬件数字触发(TTL电平)和外部时钟同步,可与其他PXI模块(如数据采集卡、数字I/O卡)协同工作。

提供FPGA兼容接口(需搭配PXI Express机箱),实现自定义实时运动算法(如前瞻控制、振动抑制)。

技术规格

参数规格

轴数2至8轴(可配置)

电机类型步进电机(2/4相)、伺服电机(直流有刷/无刷)

步进细分1/4至1/256微步(软件可调)

伺服控制PID闭环控制,支持编码器反馈(增量式/绝对式)

编码器频率最高8 MHz(差分输入)

驱动电流0.1 A至4 A(每轴独立可调)

运动模式梯形、S曲线、电子齿轮、凸轮、点位运动、连续轨迹

同步精度轴间同步误差<1μs(典型值)

接口PXI/PXI Express总线,兼容NI机箱

数字I/O 16路通用数字I/O(可配置为限位、原点、急停等)

模拟输入4路16位模拟输入(可选,用于扭矩/电流监测)

软件支持NI-Motion驱动,兼容LabVIEW、C/C++、MATLAB、Python(通过NI-DAQmx)

工作温度0°C至55°C(工业级型号支持-40°C至70°C)

尺寸标准PXI模块尺寸(3U,160 mm×100 mm)

应用场景

工业自动化

多轴机器人控制(如SCARA、Delta、六轴机械臂)、装配线定位、包装机械。

精密制造

CNC加工中心、激光切割、3D打印、半导体晶圆传输。

科研与测试

光学对准、材料拉伸试验、振动台控制、生物样本操作。

能源与交通

风电叶片测试、电动汽车电机控制、轨道交通门系统同步。

NI PXI-7350 Product Details

Product Overview

NI PXI-7350 is a high-performance motion control module launched by National Instruments(NI),designed for PXI and PXI Express systems.It supports multi-axis synchronous control(up to 8 axes),integrates stepper motor and servo motor drive functions,and is equipped with a high-speed encoder feedback interface.It is suitable for applications that require high-precision motion control,such as precision automation,robotics,CNC processing,and semiconductor testing.The module is seamlessly integrated with development environments such as LabVIEW and C/C++through the NI-Motion software driver to quickly build complex motion control systems.

Core Functions

Multi-axis synchronous control

Supports 2 to 8 axes of independent or coordinated motion,with inter-axis synchronization accuracy of up to microseconds,meeting multi-axis linkage requirements(such as robot joint control and XY platform positioning).

Each axis independently configures motion parameters(speed,acceleration,deceleration,position,etc.),and supports multiple motion modes such as trapezoidal,S-curve,electronic gear,and cam.

Stepper and servo motor drive

Stepper motor control:supports full step,half step,micro step(1/4 to 1/256 subdivision),reduces vibration and improves resolution.

Servo motor control:integrates PID closed-loop control algorithm,supports encoder feedback(incremental/absolute)and analog torque control,and achieves high-precision positioning.

Current regulation:The drive current can be set independently for each axis(0.1 A to 4 A continuously adjustable),suitable for motors of different powers.

High-speed encoder feedback

Each axis is equipped with a differential encoder input interface(ABZ phase),supports up to 8 MHz encoder frequency,and monitors the motor position and speed in real time.

Supports multiple feedback types such as orthogonal encoder,Hall sensor,SSI(synchronous serial interface),and is compatible with mainstream motor brands(such as Maxon,Faulhaber,Yaskawa).

Real-time motion monitoring and protection

Provides safety interfaces such as limit switch,origin sensor,and emergency stop input to prevent mechanical collision or overload.

Monitor motor status(such as current,temperature,encoder error)in real time and trigger alarms or protection actions through NI-DAQmx or NI-Motion API.

Flexible triggering and synchronization

Supports software triggering,hardware digital triggering(TTL level)and external clock synchronization,and can work with other PXI modules(such as data acquisition cards,digital I/O cards).

Provides FPGA-compatible interface(requires PXI Express chassis)to implement custom real-time motion algorithms(such as look-ahead control,vibration suppression).

Technical specifications

Parameter Specifications

Number of axes 2 to 8 axes(configurable)

Motor type Stepper motor(2/4 phase),servo motor(DC brushed/brushless)

Stepping subdivision 1/4 to 1/256 microstep(software adjustable)

Servo control PID closed-loop control,support encoder feedback(incremental/absolute)

Encoder frequency Up to 8 MHz(differential input)

Drive current 0.1 A to 4 A(independently adjustable for each axis)

Motion mode Trapezoidal,S-curve,electronic gear,cam,point motion,continuous trajectory

Synchronization accuracy Inter-axis synchronization error<1μs(typical)

Interface PXI/PXI Express bus,compatible with NI chassis

Digital I/O 16 general-purpose digital I/O(configurable as limit,origin,emergency stop,etc.)

Analog input 4 16-bit analog inputs(optional,for torque/current monitoring)

Software support NI-Motion driver,compatible LabVIEW,C/C++,MATLAB,Python(via NI-DAQmx)

Operating temperature 0°C to 55°C(industrial models support-40°C to 70°C)

Dimensions Standard PXI module size(3U,160 mm×100 mm)

Application scenarios

Industrial automation

Multi-axis robot control(such as SCARA,Delta,six-axis robot arm),assembly line positioning,packaging machinery.

Precision manufacturing

CNC machining center,laser cutting,3D printing,semiconductor wafer transfer.

Research and testing

Optical alignment,material tensile testing,vibration table control,biological sample manipulation.

Energy and transportation

Wind turbine blade testing,electric vehicle motor control,rail transit door system synchronization.