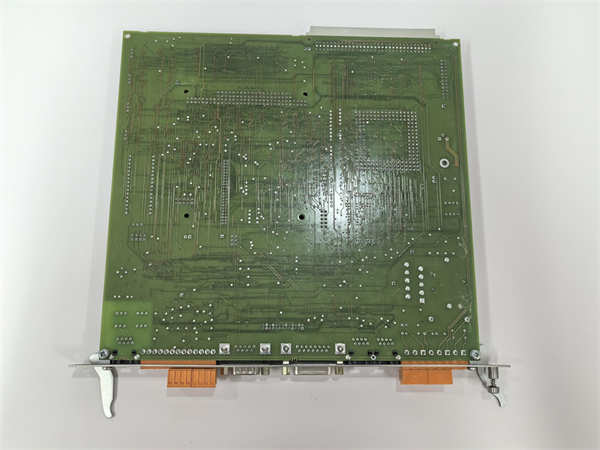

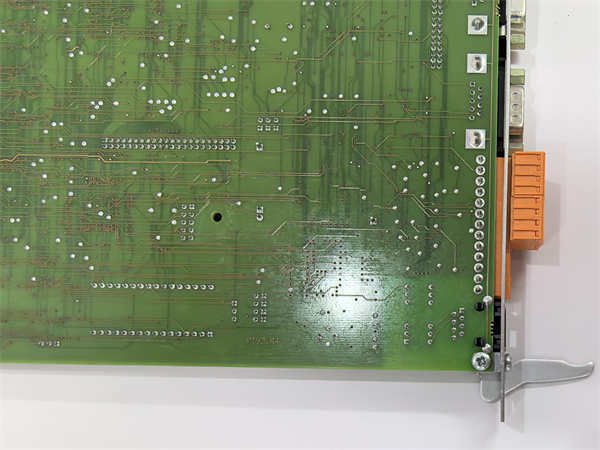

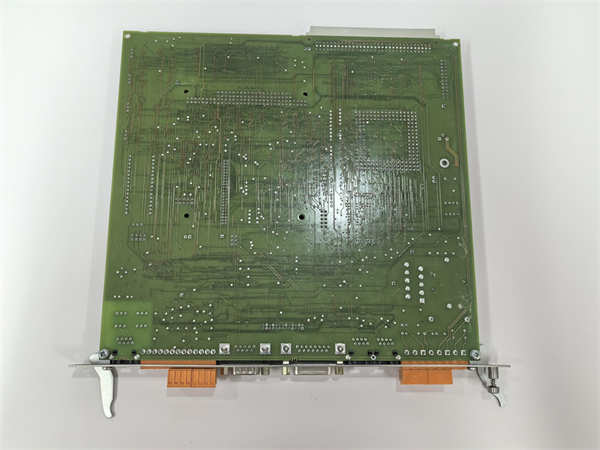

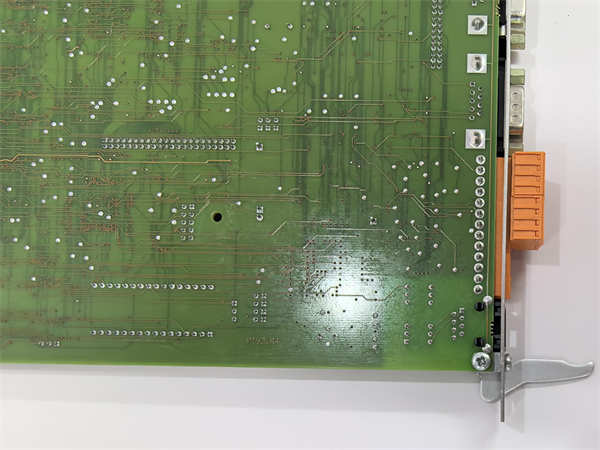

描述

PACIFIC SCIENTIFIC R43HCNA-R2-NS-VS-00是一款工业级控制器,专为机器优化与故障排除设计,通过高数据吞吐量和开放架构实现多源数据的高效采集与分析。以下是其核心功能与技术特点的综合解析:

一、核心功能定位

数据采集与分析:支持从PLC、传感器、机器视觉系统及遗留设备等多源数据的实时采集,提供微秒级循环数据记录能力,为设备性能优化和故障诊断提供依据。

EtherCAT工业以太网支持:通过EtherCAT终端(如ELM系列)实现高带宽数据传输,兼容30多种工业协议,支持混合架构部署。

二、技术参数与性能

数据处理能力

PLC数据记录:以微秒级速率捕获PLC循环数据,满足高速工业场景需求。

视觉集成:通过TwinCAT Vision解决方案,可将带有时间戳的图像嵌入机器数据流中,提升故障分析的可视化能力。

扩展性与兼容性

传感器连接:支持Vibro-Meter系列(如VM600、CMC16等)的振动传感器,实现设备健康状态监测。

协议适配:通过OPC UA服务器接口,可接入第三方设备数据,支持开放式混合架构。

保护与诊断

冗余设计:支持EtherCAT的冗余拓扑,增强系统可靠性。

TwinCAT Analytics:提供数据分析工具,实现历史数据追溯与预测性维护。

三、应用场景

智能制造:生产线设备的实时监控与异常预警,优化生产节拍。

工业视觉:结合机器视觉技术,实现产品缺陷检测与质量追溯。

设备维护:通过振动传感器数据,预测电机、轴承等关键部件的故障风险。

四、技术优势

高开放性:支持OPC UA、EtherCAT等标准协议,兼容主流工业控制系统。

低延迟:EtherCAT网络响应时间<100μs,满足高动态控制需求。

扩展灵活:可扩展至数千个I/O点,适应复杂系统集成。

P152.R4

PACIFIC SCIENTIFIC R43HCNA-R2-NS-VS-00 is an industrial-grade controller designed for machine optimization and troubleshooting.It achieves efficient collection and analysis of multi-source data through high data throughput and open architecture.The following is a comprehensive analysis of its core functions and technical features:

1.Core Function Positioning

Data Collection and Analysis:Supports real-time collection of multi-source data from PLCs,sensors,machine vision systems,and legacy equipment,and provides microsecond-level cycle data recording capabilities to provide a basis for equipment performance optimization and fault diagnosis.

EtherCAT Industrial Ethernet Support:High-bandwidth data transmission is achieved through EtherCAT terminals(such as the ELM series),compatible with more than 30 industrial protocols,and supports hybrid architecture deployment.

2.Technical Parameters and Performance

Data Processing Capabilities

PLC Data Recording:Capture PLC cycle data at a microsecond rate to meet the needs of high-speed industrial scenarios.

Visual Integration:Through the TwinCAT Vision solution,images with timestamps can be embedded in the machine data stream to improve the visualization capabilities of fault analysis.

Scalability and compatibility

Sensor connection:supports vibration sensors of the Vibro-Meter series(such as VM600,CMC16,etc.)to monitor the health status of equipment.

Protocol adaptation:Through the OPC UA server interface,third-party device data can be accessed,and open hybrid architecture is supported.

Protection and diagnosis

Redundant design:supports EtherCAT redundant topology to enhance system reliability.

TwinCAT Analytics:provides data analysis tools to achieve historical data traceability and predictive maintenance.

III.Application scenarios

Intelligent manufacturing:real-time monitoring and abnormal warning of production line equipment to optimize production rhythm.

Industrial vision:combined with machine vision technology,product defect detection and quality traceability are achieved.

Equipment maintenance:predict the failure risk of key components such as motors and bearings through vibration sensor data.

IV.Technical advantages

High openness:supports standard protocols such as OPC UA and EtherCAT,and is compatible with mainstream industrial control systems.

Low latency:EtherCAT network response time<100μs,meeting high dynamic control requirements.

Flexible expansion:can be expanded to thousands of I/O points to adapt to complex system integration.