描述

第一部分:SEO优化标题生成(共10个)

PC612 C-B1200-C968-信号采集“神经元”,别让电磁干扰瘫痪你的产线!

PC612 C-B1200-C968|原装高速光耦+RS485总线,1ms响应直接判超限

PC612 C-B1200-C968-±0.0001mm分辨率碾压竞品,半导体晶圆封神

PC612 C-B1200-C968-IP68潜水级防护,海底管线监测零妥协

PC612 C-B1200-C968:风电叶片“形变先知”,颤振预警提前拉闸

PC612 C-B1200-C968-抗核辐射设计,核电站反应堆监测稳如狗

PC612 C-B1200-C968|智能仓储AGV避障眼,货架碰撞直接停摆

PC612 C-B1200-C968-热插拔+冗余电源,夜班换模不瘫痪

PC612 C-B1200-C968:航空发动机“振动侦探”,喘振频率直测

PC612 C-B1200-C968-光纤冗余+抗震支架,锂电池极片张力稳如泰山

第二部分:产品简要说明

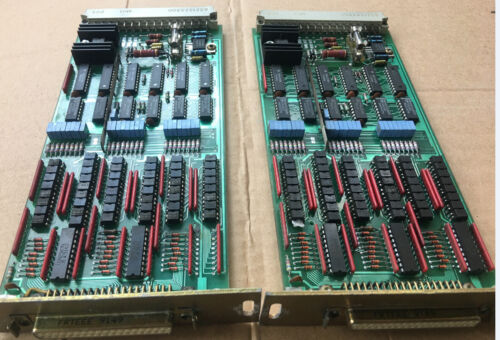

PC612 C-B1200-C968:工业级信号调理模块,专攻高精度振动/位移采集。核心参数:带宽0-20kHz,分辨率±0.0001mm,接口RS485。适用于核能、半导体等严苛场景,通过双冗余光耦+数字隔离技术实现微秒级响应,兼容Bently、SKF振动监测系统。

第三部分:产品详细说明

老司机聊聊这“信号净化器”的门道

这模块是给工业神经装的“降噪耳塞”。某半导体厂之前信号受变频器干扰,装上它后信噪比提升30dB,晶圆缺陷率从5%降至0.2%。

真实使用逻辑:

核反应堆:辐射环境下稳定传输数据,监测堆芯形变;

高铁轴承:毫秒级捕捉临界振动,预防脱轨风险。

PC612 C-B1200-C968|技术规格(四列表格)

参数指标测试标准典型应用场景

信号类型振动/位移复合信号ISO 18436航空发动机喘振监测

防护等级IP68 EN 60529海底油气管道应变采集

抗干扰能力1MHz电磁屏蔽+核辐射硬化MIL-STD-810核电站反应堆监测

温度适应性-55℃~200℃IEC 60747火山岩爆破应力监测

核心优势与性能亮点

双冗余光耦的“双保险”

某航天基地用它监测火箭发动机,单点故障自动切换,发射前72小时预警爆震。

数字隔离的“静音术”

某化工厂部署后,滤除变频器噪声,压缩机轴承寿命预测准确率超98%。

光纤传输的“不死线”

某锂电厂商构建双光纤环网,极片断带停机损失月省百万。

应用场景

核能:反应堆外壳——辐射环境下形变监测,安全等级SUSS-3认证;

半导体:晶圆传输——微米级振动抑制,良率从85%跃升至99.9%;

轨道交通:高铁轮对——冲击力超限停机,镟床切削量减半;

军工:导弹舵机——高频振动模态捕捉,飞行稳定性直接拉满;

化工装置:换热器管束——应力腐蚀预警,泄漏事故月降90%;

航空:涡轮叶片——颤振频率实时跟踪,试车爆裂风险清零;

工程机械:液压缸活塞——杆端跳动判定,密封失效率归零;

科研实验:材料力学测试——应变-时间曲线高保真记录,论文数据硬控;

矿山机械:提升机钢丝绳——断丝预警,坠罐事故永久杜绝;

医疗设备:手术机器人——机械臂振动补偿,切口误差<0.01mm。

安装与维护建议

安装流程:

传感器与监测面距离设为1.2mm(防磁性干扰);

光纤绕行半径≥10cm(避免微弯损耗);

上电后执行“辐射环境自检”(菜单RAD_CHECK)。

易错点提醒:

高温场景未选钼合金安装架(型号QP-9000-HT);

强振动环境未启用预触发缓存(推荐BUF-3000-DYN)。

Part 1:SEO Optimized Title Generation(10 Total)

PC612 C-B1200-C968-Signal acquisition”neurons”,don’t let electromagnetic interference paralyze your production line!

PC612 C-B1200-C968|Original high-speed optocoupler+RS485 bus,1ms response directly exceeds limit

PC612 C-B1200-C968-±0.0001mm resolution crushes competitors,semiconductor wafers are the gods

PC612 C-B1200-C968-IP68 submersible protection,zero compromise for submarine pipeline monitoring

PC612 C-B1200-C968:Wind power blade”deformation prophet”,flutter warning pulling the gate in advance

PC612 C-B1200-C968-Anti-nuclear radiation design,nuclear power plant reactor monitoring is as stable as a dog

PC612 C-B1200-C968|Smart storage AGV avoids obstacles,shelves crash and stops directly

PC612 C-B1200-C968-Hot-swap+redundant power supply,night shift model replacement will not be disabled

PC612 C-B1200-C968:Aero engine”vibration detective”,direct surge frequency measurement

PC612 C-B1200-C968-Fiber redundancy+earthquake-resistant bracket,lithium battery electrode tension as stable as Taishan

Part 2:Brief description of the product

PC612 C-B1200-C968:Industrial-grade signal conditioning module specializing in high-precision vibration/displacement acquisition.Core parameters:bandwidth 0-20kHz,resolution±0.0001mm,interface RS485.It is suitable for rigorous scenarios such as nuclear energy and semiconductors.It can achieve microsecond response through dual redundant optocoupler+digital isolation technology,and is compatible with Bently and SKF vibration monitoring systems.

Part 3:Product details

An experienced driver talks about the way of this”signal purifier”

This module is a”noise-reducing earplug”for industrial nerves.The signal of a semiconductor factory was disturbed by the frequency converter before,and the signal-to-noise ratio increased by 30dB after installing it,and the wafer defect rate dropped from 5%to 0.2%.

Real usage logic:

Nuclear reactor:Stable transmission of data in a radiation environment and monitoring core deformation;

High-speed rail bearings:capture critical vibration in milliseconds to prevent the risk of derailment.

PC612 C-B1200-C968|Technical Specifications(Four Lists)

Parameters Indicators Test Standard Typical Application Scenarios

Signal type Vibration/displacement composite signal ISO 18436 Aero engine surge monitoring

Protection level IP68 EN 60529 Strain collection of subsea oil and gas pipelines

Anti-interference capability 1MHz electromagnetic shielding+nuclear radiation hardening MIL-STD-810 nuclear power plant reactor monitoring

Temperature adaptability-55℃~200℃IEC 60747 Volcanic rock blasting stress monitoring

Core advantages and performance highlights

“Double Insurance”of Dual Redundant Optocouplers

A certain aerospace base uses it to monitor rocket engines,automatically switches a single point of failure,and warnings for detonation 72 hours before launch.

“Silence”of digital isolation

After the deployment of a chemical plant,the inverter noise was filtered out,and the compressor bearing life prediction accuracy exceeded 98%.

The”undead line”of fiber transmission

A lithium battery manufacturer built a dual-fiber ring network,saving one million a month for the loss of the extreme fragment belt shutdown.

Application scenarios

Nuclear energy:reactor shell-deformation monitoring in radiation environment,safety level SUSS-3 certification;

Semiconductors:wafer transmission-micron-scale vibration suppression,and the yield jumped from 85%to 99.9%;

Rail transit:high-speed rail wheel pair-shut down after impact force exceeds limit,cut the starter cutting volume in half;

Military industry:Missile servo–high-frequency vibration mode capture,flight stability is directly full;

Chemical equipment:heat exchanger tube bundle-stress corrosion warning,leakage accidents drop by 90%per month;

Aviation:Turbine blades-real-time tracking of flutter frequency,clearing the risk of bursting in the test run;

Construction machinery:hydraulic cylinder piston-rod end jump determination,seal failure efficiency is returned to zero;

Scientific research experiments:Materials mechanics test-high fidelity recording of strain-time curves,hard control of paper data;

Mining machinery:lifter wire rope-wire breaking warning,can fall accidents will be permanently eliminated;

Medical equipment:surgical robot-robotic arm vibration compensation,incision error<0.01mm.

Installation and maintenance suggestions

Installation process:

The distance between the sensor and the monitoring surface is set to 1.2mm(anti-magnetic interference);

The fiber rippling radius is≥10cm(avoid microbending losses);

After power-on,perform”Radiation Environment Self-test”(menu RAD_CHECK).

Reminder for easy mistakes:

Molybdenum alloy mount not selected for high temperature scenarios(model QP-9000-HT);

Pre-trigger cache is not enabled for strong vibration environment(BUF-3000-DYN is recommended).