描述

产品概述

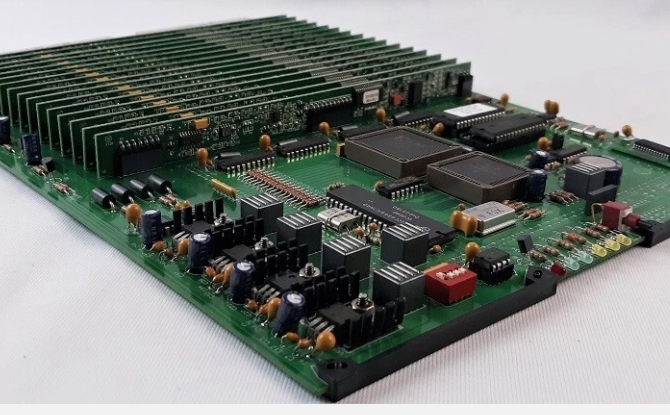

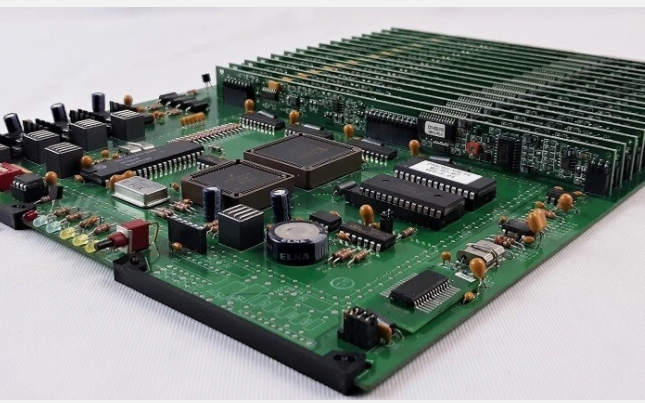

PELCO PA30-0065-00-A1是一款工业自动化通信模块,专为分布式控制系统(DCS)和工业网络设计,支持高精度时钟同步、多模式环回测试及抗干扰通信,适用于电力、能源、智能制造等领域的复杂信号传输场景。

技术参数

时钟接口与同步

时钟类型:支持线路时钟(从外部线路提取)和本地时钟(通过2.048 MHz晶振生成)。

时钟精度:频率误差≤32 ppm。

时钟模式:

线路侧发送端使用系统侧时钟,接收端使用线路恢复时钟。

支持PRBS(伪随机比特序列)测试码流插入,用于通信链路诊断。

调试与测试功能

JTAG接口:标准调试接口,支持芯片级调试与参数配置。

环回模式:

本地环回:验证模块内部信号完整性。

远端环回:测试外部链路连接状态。

净荷环回:检查数据传输准确性。

抗干扰设计

屏蔽与接地:采用隔离设计,防止屏蔽层闭合环路导致的感应电流干扰。

地环流抑制:优化接地策略,避免地电位差影响逻辑电路与模拟信号精度。

核心功能特点

高可靠性通信

支持多时隙PRBS测试码流插入,确保通信链路的稳定性和数据完整性。

通过JTAG接口实现灵活的参数配置与故障诊断。

工业级环境适应性

抗电磁干扰:屏蔽设计与隔离措施,适应工业环境中强电磁干扰场景。

宽温运行:未明确标注具体温度范围,但符合工业模块通用标准(通常-40°C至70°C)。

模块化扩展

兼容主流DCS系统(如ABB、施耐德、西门子等),支持与其他工业模块协同工作。

典型应用场景

工业自动化

作为DCS网络中的通信节点,实现设备间时钟同步与数据传输。

电力系统

在变电站或发电厂中,保障保护装置、监控系统间的高精度时序协调。

智能制造

支持机器人系统、伺服驱动器等设备的实时通信与控制。

Product Overview

PELCO PA30-0065-00-A1 is an industrial automation communication module designed for distributed control systems(DCS)and industrial networks.It supports high-precision clock synchronization,multi-mode loopback testing and anti-interference communication.It is suitable for complex signal transmission scenarios in the fields of power,energy,intelligent manufacturing,etc.

Technical parameters

Clock interface and synchronization

Clock type:Supports line clocks(extracted from external lines)and local clocks(generated via 2.048 MHz crystal).

Clock accuracy:frequency error≤32 ppm.

Clock mode:

The line-side sending end uses the system-side clock,and the receiving end uses the line-recovery clock.

Supports PRBS(pseudo-random bit sequence)test code stream insertion for communication link diagnosis.

Debugging and testing functions

JTAG interface:standard debugging interface,supports chip-level debugging and parameter configuration.

Loopback mode:

Local loopback:Verify internal signal integrity of the module.

Remote loopback:Test the external link connection status.

Payload loopback:Check the accuracy of data transmission.

Anti-interference design

Shielding and grounding:Adopt an isolation design to prevent induced current interference caused by the shielding layer closing loop.

Ground circulation suppression:Optimize the grounding strategy to avoid ground potential difference affecting the accuracy of logic circuits and analog signal.

Core functional features

High reliability communication

Supports multi-slot PRBS test code stream insertion to ensure the stability and data integrity of the communication link.

Flexible parameter configuration and fault diagnosis are realized through the JTAG interface.

Industrial-grade environmental adaptability

Anti-electromagnetic interference:shielding design and isolation measures to adapt to strong electromagnetic interference scenarios in industrial environments.

Wide temperature operation:The specific temperature range is not clearly marked,but it complies with the general standards of industrial modules(usually-40°C to 70°C).

Modular extension

Compatible with mainstream DCS systems(such as ABB,Schneider,Siemens,etc.),it supports collaborative work with other industrial modules.

Typical application scenarios

Industrial automation

As a communication node in the DCS network,clock synchronization and data transmission between devices are realized.

Power system

In substations or power plants,high-precision timing coordination between protection devices and monitoring systems is ensured.

Intelligent manufacturing

Supports real-time communication and control of robot systems,servo drives and other devices.