描述

产品简要说明

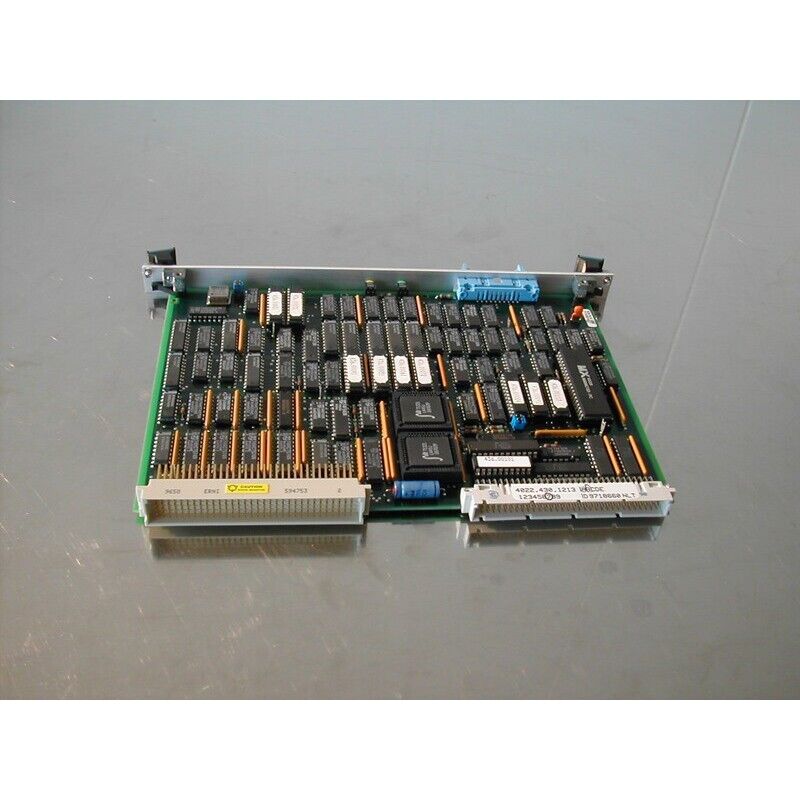

POSITION BUS CONTROLLER AA-TIS BOARD是一款专为工业自动化系统设计的高性能运动控制核心,核心功能包括:

多轴同步控制:支持16轴脉冲/方向信号输出,同步精度≤100ns。

实时通信协议:兼容EtherCAT、Profinet及CANopen,主站刷新周期≤200μs。

智能诊断系统:集成硬件级故障检测模块,支持在线诊断与日志记录。

产品详细说明

1.技术架构与创新

分布式控制架构:

多核异步处理:采用双ARM Cortex-R5处理器(主频400MHz),独立处理运动控制与通信任务。

硬件加速引擎:内置FPGA逻辑单元,运动指令执行效率提升30%。

总线协议适配:

EtherCAT优化:支持动态从站配置,节点延迟波动≤20ns。

兼容性扩展:可通过固件升级适配Profinet RT、CANopen FD等协议。

2.核心功能模块

运动控制算法:

插补算法库:支持直线、圆弧、螺旋线插补,轨迹跟踪误差≤0.01%。

动态补偿:集成电机齿槽效应补偿、负载惯量自适应调整模块。

安全防护机制:

冗余通信链路:双EtherCAT环网拓扑,单链路故障切换时间<5ms。

紧急制动控制:支持安全扭矩关断(STO)功能,制动响应时间≤50μs。

3.行业应用适配性

半导体制造:

晶圆台控制:驱动直线电机实现±20μm行程定位,重复精度≤0.5μm。

真空环境兼容:通过ISO 14644-1 Class 1洁净室认证,微粒排放≤0.1个/m³(0.1μm)。

精密加工设备:

五轴联动加工:同步控制主轴与四个旋转轴,加工节拍提升25%。

温度补偿:集成热电偶接口,实时补偿环境温度变化导致的机械形变。

Product brief description

POSITION BUS CONTROLLER AA-TIS BOARD is a high-performance motion control core designed for industrial automation systems,with core functions including:

Multi-axis synchronization control:supports 16-axis pulse/direction signal output,synchronization accuracy≤100ns.

Real-time communication protocol:compatible with EtherCAT,Profinet and CANopen,the main site refresh cycle is≤200μs.

Intelligent diagnostic system:Integrated hardware-level fault detection module,supporting online diagnosis and logging.

Product details

1.Technical Architecture and Innovation

Distributed control architecture:

Multi-core asynchronous processing:adopts dual ARM Cortex-R5 processor(main frequency 400MHz)to independently handle motion control and communication tasks.

Hardware acceleration engine:built-in FPGA logic unit,and the efficiency of motion command execution is increased by 30%.

Bus protocol adaptation:

EtherCAT optimization:supports dynamic slave configuration,node delay fluctuation≤20ns.

Compatibility extension:It can be upgraded through firmware to adapt to Profinet RT,CANopen FD and other protocols.

2.Core functional modules

Motion control algorithm:

Interpolation algorithm library:supports linear,arc,and spiral interpolation,and the tracking error is≤0.01%.

Dynamic compensation:integrated motor cogging effect compensation,load inertia adaptive adjustment module.

Safety protection mechanism:

Redundant communication link:dual EtherCAT ring topology,single link failover time<5ms.

Emergency braking control:supports safe torque off(STO)function,and the braking response time is≤50μs.

3.Industry application adaptability

Semiconductor manufacturing:

Wafer control:Drive linear motor to achieve±20μm stroke positioning,and repeatability accuracy is≤0.5μm.

Vacuum environment compatibility:passed ISO 14644-1 Class 1 clean room certification,particle emissions≤0.1 units/m³(0.1μm).

Precision processing equipment:

Five-axis linkage machining:synchronously control the spindle and four rotation axes,and the machining beat is increased by 25%.

Temperature compensation:Integrated thermocouple interface to compensate for mechanical deformation caused by ambient temperature changes in real time.