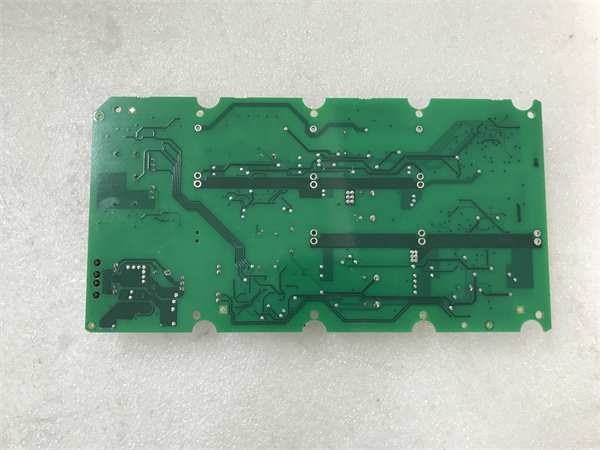

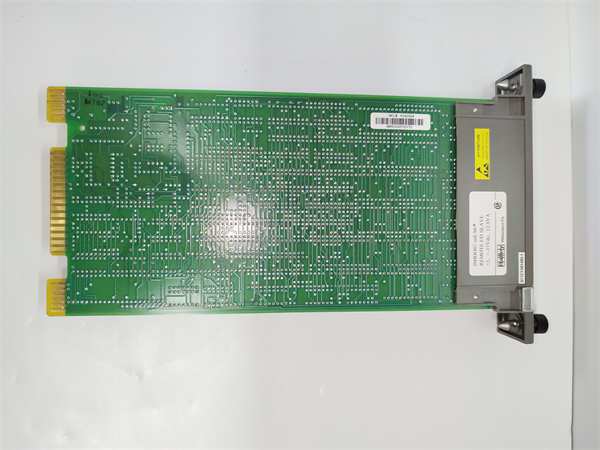

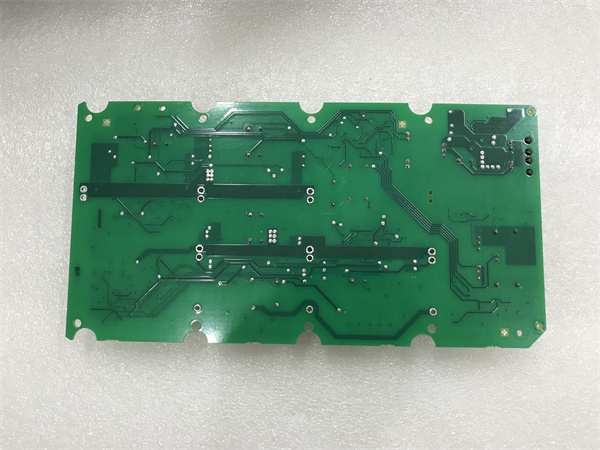

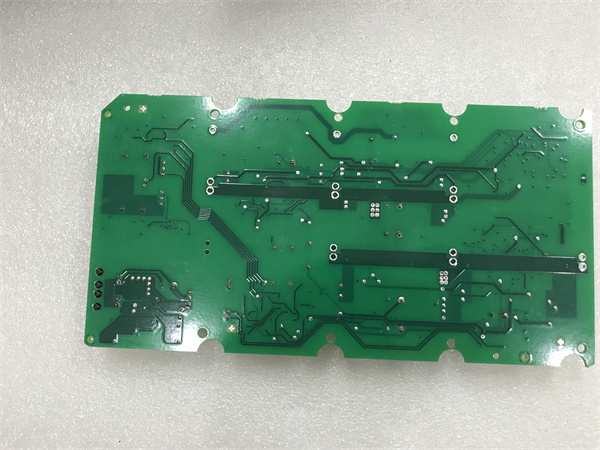

描述

RELIANCE ELECTRIC S-D4012控制脉冲定时器技术说明

核心功能

工业级速度控制与信号处理

磁性拾取器(MPU):实时检测原动机转速,将机械信号转换为电信号,支持频率-电压转换器处理,确保内部电路精准响应。

多级控制逻辑:集成速度比较器、加法器/放大器及致动器阀门,实现燃油或蒸汽机构的动态调节,保障设备稳定运行。

灵活的输出与通信能力

继电器与晶体管输出:配备两个SPDT继电器(支持10-32V电源设备控制)及集电极开路晶体管,可直接驱动阀门、泵或连接PLC/BMS系统。

远程监控接口:内置RS485串行通信端口,支持工业级数据传输,便于集成到自动化监控网络。

技术参数

电源要求:

低压供电:10-24Vac或12-32Vdc,适应多种工业电源环境。

处理器性能:

基于Intel Atom四核处理器E3845(1.9GHz),支持IEC-61131标准编程,兼容Sofotion功能块开发。

I/O扩展能力:

单控制器支持64个轴和10,000个I/O控制点(通过菊花链连接),满足大规模自动化系统需求。

环境适应性:

工作温度:-20°C至60°C(工业宽温设计),抗振动/冲击,防护等级IP65/IP67。

设计亮点

高可靠性与容错机制

自检功能:可检测传感电缆损坏或端接异常,自动触发报警并分配继电器输出响应故障。

冗余设计:支持热插拔维护,保障关键控制链路连续运行。

多协议兼容性

通信接口:兼容RS485、Modbus、OPC UA等工业协议,支持与PLC、HMI、SCADA系统无缝对接。

编程语言:支持梯形图(LD)、结构化文本(ST)、顺序功能图(SFC)等IEC-61131标准语法。

应用场景

工业自动化:泵站、阀门控制、生产线协调等高精度场景。

能源管理:发电厂、燃气轮机的燃料/蒸汽调节系统。

楼宇与建筑:BMS系统集成,实现空调、消防设备的智能联动。

REF615E_E HBFHAEAGNCA1BNN1XE

REF615C_C HCFFAEAGANB2BAN1XC

RELIANCE ELECTRIC S-D4012 Technical Description of Control Pulse Timer

Core functions

Industrial-grade speed control and signal processing

Magnetic pickup(MPU):detects the prime mover speed in real time,converts mechanical signals into electrical signals,supports frequency-voltage converter processing,and ensures accurate response of internal circuits.

Multi-stage control logic:Integrate speed comparator,adder/amplifier and actuator valve to realize dynamic adjustment of fuel or steam mechanisms and ensure stable operation of the equipment.

Flexible output and communication capabilities

Relay and transistor output:equipped with two SPDT relays(supporting 10-32V power supply equipment control)and open collector transistors,which can directly drive valves,pumps or connect to PLC/BMS systems.

Remote monitoring interface:Built-in RS485 serial communication port,supports industrial-grade data transmission,and is easy to integrate into an automated monitoring network.

Technical parameters

Power requirements:

Low voltage power supply:10-24Vac or 12-32Vdc,adapted to a variety of industrial power environments.

Processor performance:

Based on Intel Atom quad-core processor E3845(1.9GHz),it supports IEC-61131 standard programming and is compatible with Sofotion function block development.

I/O expansion capability:

The single controller supports 64 axes and 10,000 I/O control points(connected via daisy chain),meeting the needs of large-scale automation systems.

Environmental adaptability:

Operating temperature:-20°C to 60°C(industrial wide temperature design),vibration/impact resistance,protection level IP65/IP67.

Design Highlights

High reliability and fault tolerance mechanism

Self-test function:It can detect damage or termination abnormality of the sensing cable,automatically trigger an alarm and allocate the relay output response fault.

Redundant design:supports hot-swap maintenance and ensures continuous operation of critical control links.

Multi-protocol compatibility

Communication interface:compatible with industrial protocols such as RS485,Modbus,OPC UA,etc.,and supports seamless connection with PLC,HMI,and SCADA systems.

Programming language:Supports IEC-61131 standard syntax such as ladder diagram(LD),structured text(ST),sequential function diagram(SFC).

Application scenarios

Industrial automation:high-precision scenarios such as pump stations,valve control,production line coordination,etc.

Energy management:Fuel/steam regulation system for power plants and gas turbines.

Building and building:BMS system integration to realize intelligent linkage between air conditioning and fire-fighting equipment.