描述

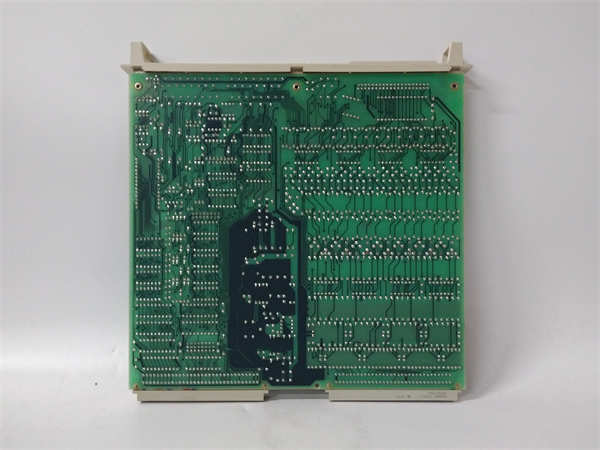

Reliance Electric P56H5047G是一款工业自动化控制模块,专为复杂工艺控制场景设计,结合了高效处理能力与灵活扩展性。以下是其核心功能、技术参数及应用场景的综合概述:

一、核心功能与技术参数

模块规格

-型号:P56H5047G

-结构形式:整体式控制室安装

-工作电压:24V DC

-输出频率:12Hz

-处理速度:32MHz

-程序容量:48KB

-数据容量:45KB

-环境适应性:-4℃至+40℃(环境温度)、湿度≤20%RH

-认证:符合工业级安全标准

核心功能

-精准控制:支持小型机床等设备的严格生产节拍控制,适用于烟草行业糖料、香料工序的流量信号同步。

-再生制动管理:具备电气再生制动功能,通过电容器存储制动能量,制动力可达额定转矩的10%-20%;可选配制动单元提升至50%-100%。

-转矩提升:优化快速门电机的动态响应,支持工艺参数灵活调整。

二、应用场景

工业自动化

-机床控制:适用于小型数控机床,精准控制加工节拍与运动轨迹。

-风机传动:需长加速/减速过程的场合,可通过参数协同优化效率。

-快速门系统:管理电机启停及再生能量回收,提升响应速度。

特殊行业应用

-烟草加工:通过皮带称流量信号实时调节变频器频率,确保工艺一致性。

-物流分拣:协同机器人系统实现高效分拣与设备联动。

三、技术优势

高可靠性

-工业级设计:非定制化模块,适配长期运行环境。

-容错机制:直流回路电压异常时,可快速定位接触器主触点故障并修复。

-抗干扰能力:滤波电容器与光电隔离技术减少电磁干扰。

扩展性

-通信接口:支持Modbus、Profibus等协议,兼容主流控制系统。

-模块化兼容:可集成至Reliance Electric或其他品牌自动化平台。

DSAI130 57120001-P5

DSAI130 57120001-P5

Reliance Electric P56H5047G is an industrial automation control module designed for complex process control scenarios,combining efficient processing capabilities with flexible scalability.The following is a comprehensive overview of its core functions,technical parameters and application scenarios:

I.Core functions and technical parameters

Module specifications

-Model:P56H5047G

-Structure:integrated control room installation

-Operating voltage:24V DC

-Output frequency:12Hz

-Processing speed:32MHz

-Program capacity:48KB

-Data capacity:45KB

-Environmental adaptability:-4℃to+40℃(ambient temperature),humidity≤20%RH

-Certification:Complies with industrial safety standards

Core functions

-Precision control:Supports strict production rhythm control of small machine tools and other equipment,suitable for flow signal synchronization of sugar and flavor processes in the tobacco industry

-Regenerative braking management:With electrical regenerative braking function,the braking energy can be stored by capacitors,and the braking force can reach 10%-20%of the rated torque;the optional braking unit can be increased to 50%-100%.

-Torque boost:Optimize the dynamic response of the fast door motor and support flexible adjustment of process parameters.

2.Application scenarios

Industrial automation

-Machine tool control:Suitable for small CNC machine tools,accurately control the processing beat and motion trajectory.

-Fan drive:In situations where a long acceleration/deceleration process is required,the efficiency can be optimized through parameter coordination.

-Fast door system:Manage motor start and stop and regenerative energy recovery to improve response speed.

Special industry applications

-Tobacco processing:Real-time adjustment of the inverter frequency through the belt scale flow signal to ensure process consistency.

-Logistics sorting:Collaborative robot system realizes efficient sorting and equipment linkage.

3.Technical advantages

High reliability

-Industrial-grade design:Non-customized module,adapted to long-term operating environment.

-Fault-tolerant mechanism:When the DC circuit voltage is abnormal,the main contact fault of the contactor can be quickly located and repaired.

-Anti-interference capability:filter capacitors and photoelectric isolation technology reduce electromagnetic interference.

Expandability

-Communication interface:supports Modbus,Profibus and other protocols,compatible with mainstream control systems.

-Modular compatibility:can be integrated into Reliance Electric or other brand automation platforms.