描述

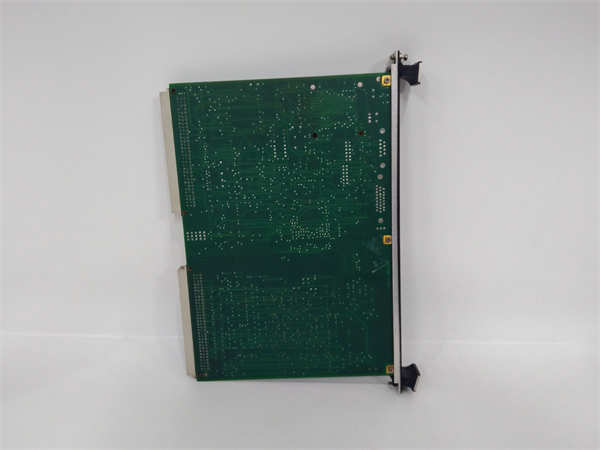

REXROTH VT-HNC100-1-22/W-08-0-0是博世力士乐(Bosch Rexroth)推出的一款高性能数字轴控制器,专为工业自动化和液压驱动系统设计,适用于高精度运动控制场景。以下是其核心功能与技术参数的综合解析:

一、核心功能与技术特点

多轴控制能力

-最多控制4个轴:支持四轴联动控制,适用于复杂运动轨迹规划和同步操作,满足精密机床、机器人等设备需求。

-液压驱动闭环控制:针对液压系统优化设计,提供位置、压力/力的闭环控制,确保高动态响应和稳定性。

灵活的接口配置

-8个数字输入/输出:支持数字信号交互,可连接传感器、执行器等设备。

-总线连接:兼容PROFIBUS DP等工业总线协议,便于集成到自动化网络中。

-模拟信号接口:支持电压(0-±10V)、电流(4-20mA)及SSI串行接口的模拟量输入输出,适应不同传感器类型。

高精度与动态性能

-μ级定位精度:通过高分辨率编码器反馈(23位分辨率)和自适应补偿算法,重复定位精度可达±0.001mm,适用于精密加工场景。

-微秒级响应:电流环刷新周期低至62.5μs,速度环响应频率达3kHz,可快速响应负载变化。

智能化与诊断功能

-预测性维护:集成温度、振动等传感器数据,实时分析设备健康状态,降低故障风险。

-在线诊断:通过LED指示灯和PC软件显示轴状态、故障代码及性能参数,简化维护流程。

二、技术参数

电源要求:18-36V DC,内部功耗8W。

防护等级:抗振动、冲击设计,符合工业环境标准。

编程语言:支持G代码、PLCopen等,配备图形化界面简化配置。

安装方式:壁挂式外壳,适合紧凑型设备布局。

三、典型应用场景

工业机械:机床、印刷机、转移线的高精度运动控制。

机器人技术:多轴协作机器人的轨迹规划与同步控制。

能源领域:液压阀门定位、压力控制系统。

轨道交通:列车液压制动系统的精准调控。

IS215UCCCM04AB

IS220UCSAH1AK

REXROTH VT-HNC100-1-22/W-08-0-0 is a high-performance digital axis controller launched by Bosch Rexroth,designed for industrial automation and hydraulic drive systems,suitable for high-precision motion control scenarios.The following is a comprehensive analysis of its core functions and technical parameters:

I.Core functions and technical features

Multi-axis control capability

-Control up to 4 axes:Support four-axis linkage control,suitable for complex motion trajectory planning and synchronous operation,meeting the needs of precision machine tools,robots and other equipment.

-Hydraulic drive closed-loop control:Optimized design for hydraulic systems,providing closed-loop control of position,pressure/force,ensuring high dynamic response and stability.

Flexible interface configuration

-8 digital inputs/outputs:Support digital signal interaction,can connect sensors,actuators and other devices.

-Bus connection:Compatible with industrial bus protocols such as PROFIBUS DP,easy to integrate into automation networks.

-Analog signal interface:supports analog input and output of voltage(0-±10V),current(4-20mA)and SSI serial interface,adapting to different sensor types.

High precision and dynamic performance

-μ-level positioning accuracy:through high-resolution encoder feedback(23-bit resolution)and adaptive compensation algorithm,the repeat positioning accuracy can reach±0.001mm,which is suitable for precision machining scenarios.

-Microsecond response:the current loop refresh cycle is as low as 62.5μs,and the speed loop response frequency is 3kHz,which can quickly respond to load changes.

Intelligence and diagnostic functions

-Predictive maintenance:integrates sensor data such as temperature and vibration,analyzes the health status of the equipment in real time,and reduces the risk of failure.

-Online diagnosis:displays the axis status,fault code and performance parameters through LED indicators and PC software to simplify the maintenance process.

2.Technical parameters

Power requirements:18-36V DC,internal power consumption 8W.

Protection level:anti-vibration and impact design,in line with industrial environment standards.

Programming language:supports G code,PLCopen,etc.,equipped with a graphical interface to simplify configuration.

Installation method:wall-mounted housing,suitable for compact equipment layout.

3.Typical application scenarios

Industrial machinery:high-precision motion control of machine tools,printing presses,and transfer lines.

Robotics:trajectory planning and synchronous control of multi-axis collaborative robots.

Energy field:hydraulic valve positioning,pressure control system.

Railway transportation:precise control of train hydraulic braking system.