描述

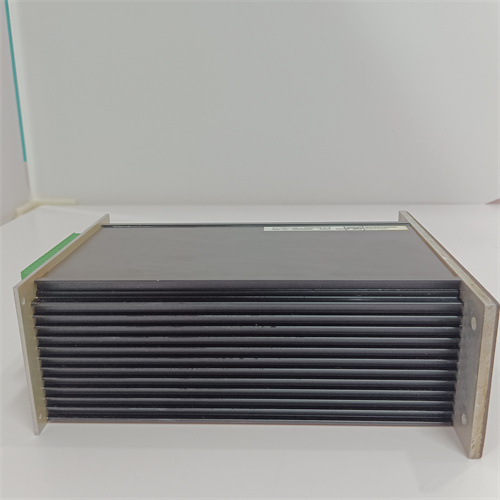

REXROTH VT-HNC100-1-22W-08-C-0是博世力士乐(Bosch Rexroth)公司生产的一款数字轴控制器,主要用于液压驱动控制领域,以下是其产品详情:

功能特点

控制轴数:可用于控制1个液压轴。

安装方式:采用壁挂式安装外壳,方便安装在合适的位置。

输入输出:配备8个数字输入输出端口,可用于与其他设备进行信号交互,实现各种控制功能。

多种控制模式:支持位置调节、力调节、压力调节、分离位置/力调节或位置/力调节、速度调节等多种控制模式,还能根据行程制动以及实现同步(主/从或平均值原则),可以满足不同应用场景的需求。

总线连接:支持Sercos、PROFINET RT、EtherNet/IP等总线连接方式,能够方便地与其他设备进行通信和集成,实现系统的自动化控制。

实际值感测:可连接多种类型的位置编码器,包括增量式、绝对值(SSI)、EnDat2.2(Sercos型),也能接收模拟式0至±10V和4至20mA的信号,以精确感测实际位置或其他物理量。

调节值输出:提供电压或电流形式的调节值输出端,可将控制信号输出到外部设备,实现对液压系统的精确控制。

故障保护与诊断:具备多种内置的先进保护功能,如欠压和过流保护,其故障检测功能还能检测通信错误和电缆断裂等错误,可显著减少停机时间,降低维修成本。

软件支持:使用WinPed7或IndraWorks软件进行参数设置、编程和诊断等操作。通过这些软件,用户可以方便地对控制器进行配置和监控,实现各种复杂的控制功能。

适用领域:适用于各种需要高精度液压控制的工业自动化场景,如机床、注塑机、压铸机、自动化生产线等设备的液压系统控制,能够提高设备的性能和精度,实现高效、稳定的运行。

REXROTH VT-HNC100-1-22W-08-C-0 is a digital axis controller produced by Bosch Rexroth,mainly used in the field of hydraulic drive control.The following are its product details:

Functional features

Number of controlled axes:can be used to control 1 hydraulic axis.

Installation method:wall-mounted housing is used for easy installation in a suitable location.

Input and output:equipped with 8 digital input and output ports,which can be used for signal interaction with other devices to achieve various control functions.

Multiple control modes:supports multiple control modes such as position adjustment,force adjustment,pressure adjustment,separate position/force adjustment or position/force adjustment,speed adjustment,etc.,and can also brake according to the stroke and achieve synchronization(master/slave or average value principle),which can meet the needs of different application scenarios.

Bus connection:supports Sercos,PROFINET RT,EtherNet/IP and other bus connection methods,which can easily communicate and integrate with other devices to achieve system automation control.

Actual value sensing:It can connect various types of position encoders,including incremental,absolute(SSI),EnDat2.2(Sercos type),and can also receive analog 0 to±10V and 4 to 20mA signals to accurately sense the actual position or other physical quantities.

Adjustment value output:It provides adjustment value output terminals in the form of voltage or current,and can output control signals to external devices to achieve precise control of the hydraulic system.

Fault protection and diagnosis:It has a variety of built-in advanced protection functions,such as undervoltage and overcurrent protection.Its fault detection function can also detect errors such as communication errors and cable breaks,which can significantly reduce downtime and maintenance costs.

Software support:Use WinPed7 or IndraWorks software for parameter setting,programming and diagnosis.Through these software,users can easily configure and monitor the controller to achieve various complex control functions.

Applicable fields:Suitable for various industrial automation scenarios that require high-precision hydraulic control,such as hydraulic system control of machine tools,injection molding machines,die-casting machines,automated production lines and other equipment,which can improve the performance and precision of the equipment and achieve efficient and stable operation.