描述

主要产品详情及功能

数字轴控制(HNC100系列):这是一款可编程数控(NC)单元,专为单轴精确动态控制而优化。它既可与液压驱动器配合使用(例如,控制气缸或电机的比例阀或伺服阀),也可在某些配置下与电气驱动器配合使用。

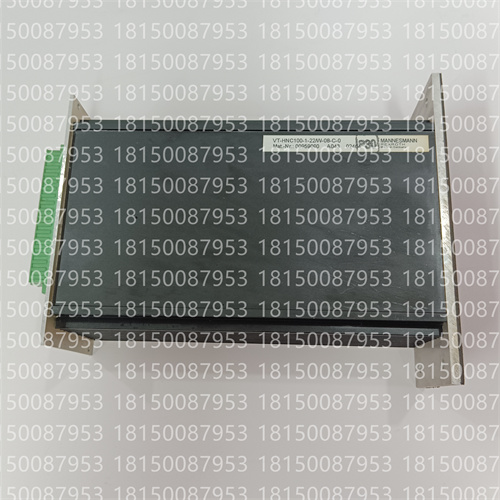

单轴版本:型号中的“1”(VT-HNC100-1-22W-08-C-0)表示该单元配置用于控制单液压轴。

组件系列20-29:型号中的“22”(VT-HNC100-1-22W-08-C-0)表示它属于组件系列20至29。这些系列的安装和连接尺寸保持不变,确保在该范围内兼容性强且易于更换。

壁挂式外壳(“W”):“W”表示该装置采用壁挂式外壳设计。其他选项可能包括机架安装。

8路数字输入/输出(“08”):这指定了集成数字I/O的数量。该装置具有8路数字输入和8路数字输出,可与其他机器组件进行基本的信号传输和控制集成。

控制类型(“C”):型号(VT-HNC100-1-22W-08-C-0)中的“C”可能表示特定的控制功能或软件配置,例如“位置/压力”控制版本或标准控制版本。

闭环控制功能:

位置控制器:用于线性轴或旋转轴的高精度定位控制。

压力/力控制器:适用于需要精确控制液压或力的应用。

交替闭环控制:可根据需要在位置控制和压力/力控制之间切换。

位置相关制动:可根据轴的位置实现精确减速。

多功能传感器和控制接口:

位置反馈:支持增量式和绝对式(SSI)编码器,实现精确位置测量。

模拟量I/O:提供用于传感器的模拟量输入(例如0至±10 V和4至20 mA),以及用于控制阀门或驱动器的模拟量输出。

数字量I/O:如上所述,提供8个用于离散信号的数字量输入和输出。

参考电压:提供±10 V参考电压。

与上级控制器的连接:HNC100可通过以下方式与上级控制器(PLC、HMI)连接:

模拟信号

数字输入/输出

串行接口

可选现场总线系统(例如Profibus DP、CANopen、INTERBUS-S、SERCOS-尽管部件号中的“C”通常表示标准或特定配置,但不一定代表所有现场总线标准)。

坚固的工业设计:HNC100专为恶劣的工业环境而设计,具有强大的抗干扰能力、抗机械振动和冲击能力以及耐候性。它符合CE指令。

软件配置:操作依赖于使用WIN-PED等软件在PC上创建的特定于应用程序的数据集。这些数据集随后通过串行接口传输到HNC100。该软件还有助于参数化、编程、编辑和诊断设备。

安全和诊断功能:

动态跟随误差监控。

行程范围限制(电子限位开关)。

增量式/SSI编码器和4-20 mA传感器的电缆断裂监控。

故障检测,输出禁用。

电源:标称电压24 VDC(通常为18至36 VDC)。

通用规格

制造商:博世力士乐

产品类型:数字轴控制/运动控制器

系列:VT-HNC100

轴数:1(单液压轴或电动轴)

数字I/O:8路数字输入/8路数字输出

模拟I/O:多路模拟输入(电压/电流)和输出(电压/电流)。

位置反馈:支持增量式和SSI编码器。

处理器:通常为MC68376 16/32位处理器。

内存:例如:1 MB Flash EPROM、8 KB EEPROM、256 KB RAM。

工作温度:通常为0°C至+50°C。

安装方式:壁挂式外壳。

状态:此系列(包括VT-HNC100)已停产。

Key Product Details and Functions

Digital Axis Control(HNC100 Series):This is a programmable NC(Numerical Control)unit specifically optimized for precise and dynamic control of one axis.It can be used with both hydraulic drives(e.g.,controlling proportional or servo valves for cylinders or motors)and,in some configurations,electric drives.

Single-Axis Version:The”1″in the model number(VT-HNC100-1-22W-08-C-0)indicates that this particular unit is configured for controlling one hydraulic axis.

Component Series 20-29:The”22″in the model number(VT-HNC100-1-22W-08-C-0)signifies it belongs to component series 20 to 29.These series maintain unchanged installation and connection dimensions,ensuring compatibility and ease of replacement within that range.

Housing for Wall-Mounting(“W”):The”W”indicates that the unit comes in a housing designed for wall-mounting.Other options might include rack installation.

8 Digital Inputs/Outputs(“08”):This specifies the number of integrated digital I/O.The unit features 8 digital inputs and 8 digital outputs,allowing for basic signaling and control integration with other machine components.

Control Type(“C”):The”C”in the model number(VT-HNC100-1-22W-08-C-0)likely indicates a specific control functionality or software configuration,such as a”position/pressure”control variant or a standard control version.

Closed-Loop Control Capabilities:

Position Controller:Highly accurate positioning control for linear or rotary axes.

Pressure/Force Controller:For applications requiring precise control of hydraulic pressure or force.

Alternating Closed-Loop Control:Can switch between position and pressure/force control as needed.

Position-Dependent Braking:Allows for precise deceleration based on the axis’s position.

Versatile Sensor and Control Interfaces:

Position Feedback:Supports both incremental and absolute(SSI)encoders for precise position measurement.

Analog I/O:Features analog inputs(e.g.,0 to±10 V and 4 to 20 mA)for sensors and analog outputs for controlling valves or drives.

Digital I/O:As mentioned,8 digital inputs and outputs for discrete signals.

Reference Voltage:Provides a±10 V reference voltage.

Connectivity to Higher-Level Control:The HNC100 can interface with higher-level controllers(PLCs,HMIs)via:

Analog signals

Digital inputs/outputs

Serial interface

Optional Fieldbus systems(e.g.,Profibus DP,CANopen,INTERBUS-S,SERCOS-though the”C”in the part number usually indicates a standard or specific configuration without necessarily all fieldbuses standard).

Robust Industrial Design:The HNC100 is engineered for use in harsh industrial environments,with strong immunity to interference,mechanical resistance to vibration and shock,and climate-proofness.It conforms with CE Directives.

Software Configuration:Operation relies on application-specific data sets created on a PC using software like WIN-PED.These datasets are then transferred to the HNC100 via its serial interface.This software also aids in parameterizing,programming,editing,and diagnosing the unit.

Safety and Diagnostic Features:

Dynamic following error monitoring.

Traversing range limits(electronic limit switches).

Cable break monitoring for incremental/SSI encoders and 4-20 mA sensors.

Fault detection with output deactivation.

Power Supply:Operates on a 24 VDC nominal voltage(typically 18 to 36 VDC range).

General Specifications

Manufacturer:Bosch Rexroth

Product Type:Digital Axis Control/Motion Controller

Series:VT-HNC100

Axes:1(single hydraulic or electric axis)

Digital I/O:8 digital inputs/8 digital outputs

Analog I/O:Multiple analog inputs(voltage/current)and outputs(voltage/current).

Position Feedback:Supports Incremental and SSI encoders.

Processor:Typically an MC68376 16/32-bit processor.

Memory:E.g.,1 MB Flash EPROM,8 KB EEPROM,256 KB RAM.

Operating Temperature:Typically 0°C to+50°C.

Mounting:Wall-mount housing.

Status:This series,including the VT-HNC100,is discontinued by the manufacturer.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101