描述

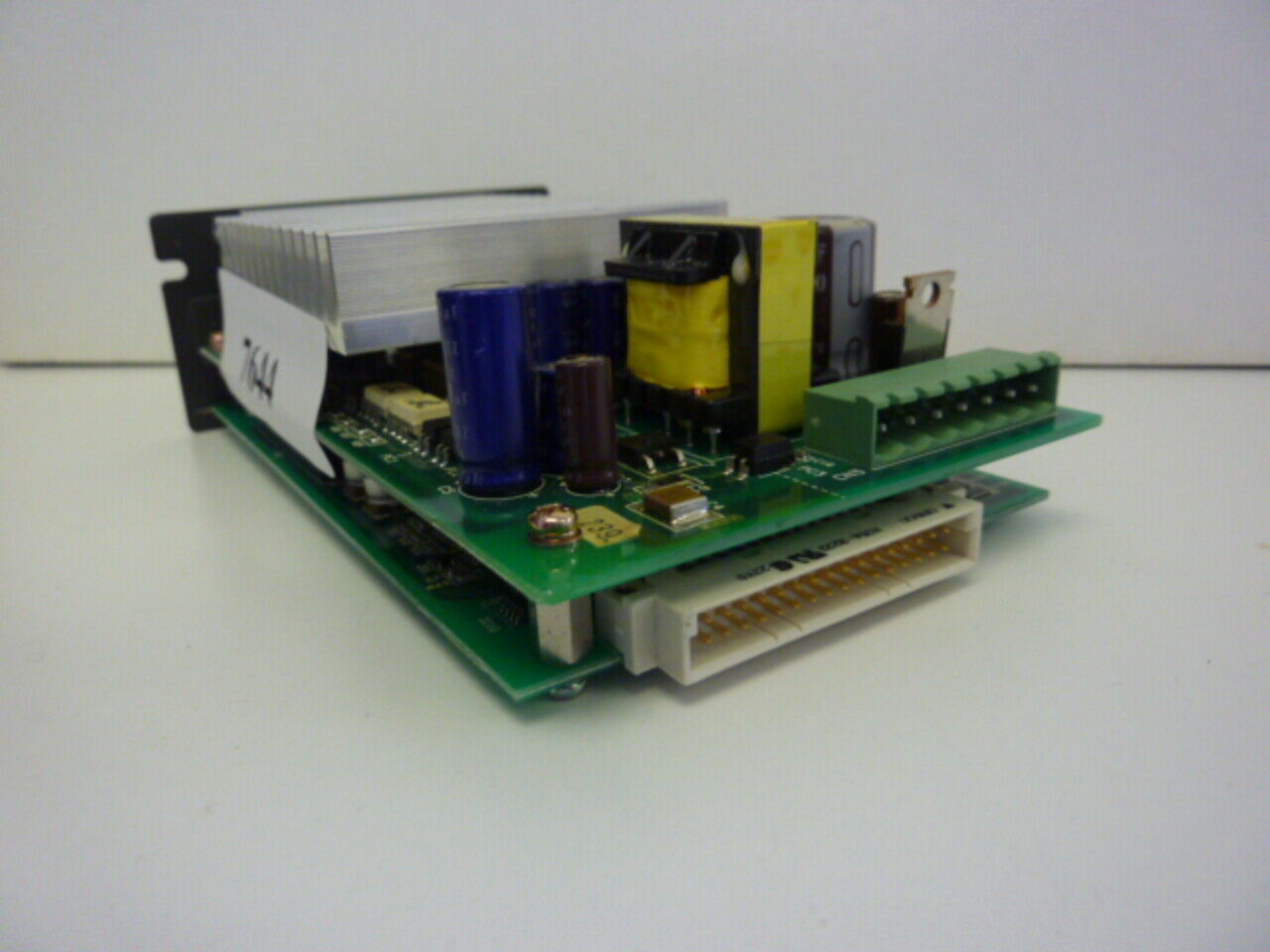

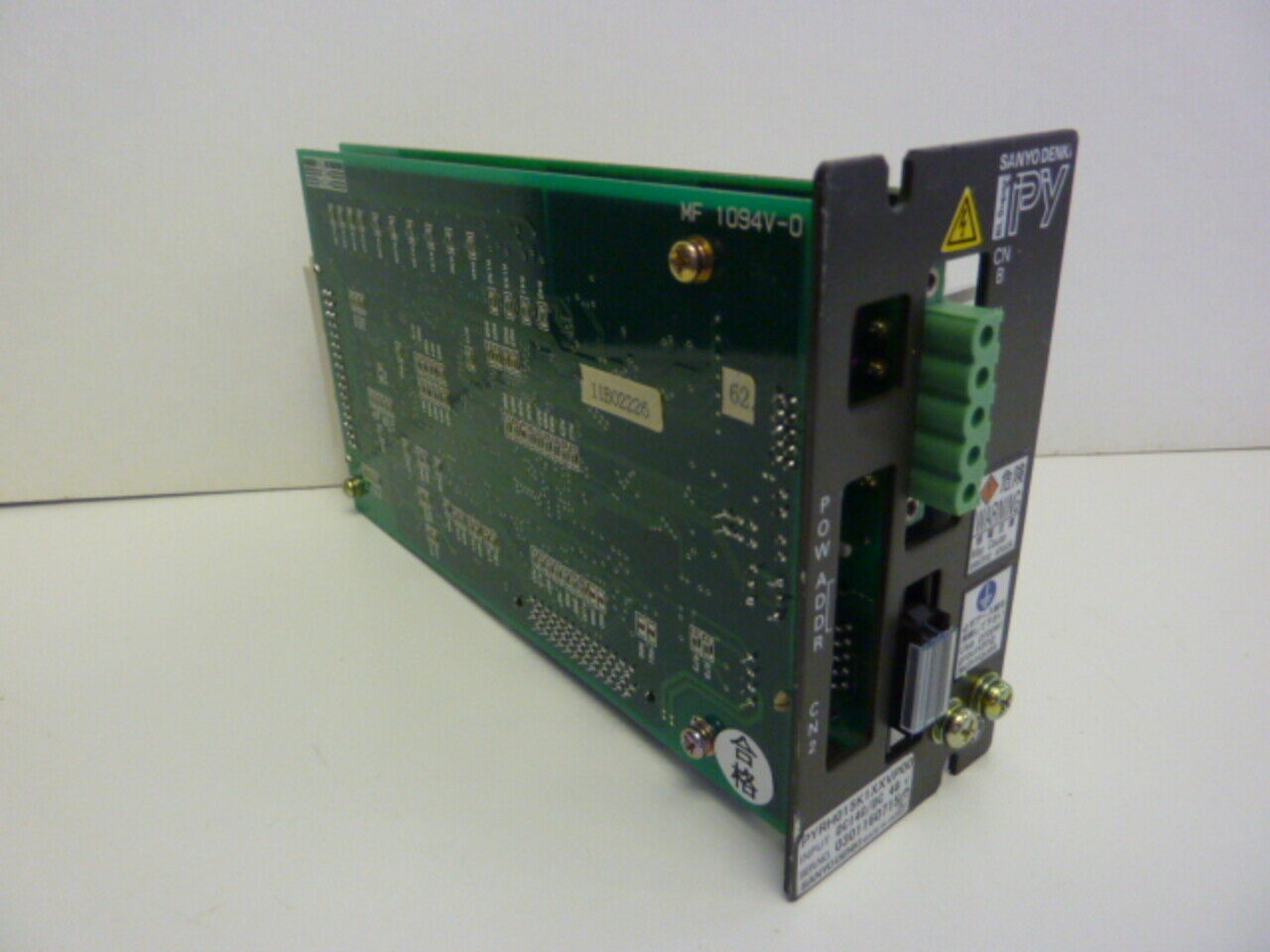

SANYO DENKI-769547产品概述

SANYO DENKI-769547是一款模块化高性能伺服电机,作为SANYO DENKI旗下SANMOTION系列的中坚型号,专为灵活配置与高效驱动的自动化系统量身打造。该产品采用模块化设计,可灵活组合电机本体、编码器与冷却模块,满足不同应用场景的定制需求。核心功能涵盖动态扭矩控制、多协议通信、故障诊断与能效管理,所属SANMOTION R系列平台赋予其卓越的兼容性与扩展性。在自动化系统中,SANYO DENKI-769547定位为“灵活驱动解决方案”,通过模块化架构与高性能参数平衡,为设备制造商提供从标准应用到非标设计的快速适配能力,显著降低集成成本与周期。

主要特点和优势

SANYO DENKI-769547的技术特性与竞争优势体现在以下维度:

1.模块化设计与快速适配

支持电机本体、编码器(17位绝对值型/增量型可选)、冷却模块(风冷/液冷)的自由组合,适配机床、包装机械等不同散热需求。

2.高性能参数平衡

额定扭矩覆盖10-50Nm,转速范围0-6000rpm,兼顾中负载场景的扭矩输出与高速运转需求。

3.动态扭矩优化(DTC)技术

实时计算负载惯量与摩擦系数,动态调整电流矢量,提升系统响应速度30%。支持动态扭矩补偿(DDC),减少机械冲击。

4.多协议兼容与灵活通信

集成EtherCAT、Profinet、Modbus-TCP三合一通信接口,无需额外适配器即可接入主流自动化系统。

5.智能能效管理

采用动态电流优化(DCC)与再生能量回馈(REG)技术,综合节能效率达25%。空载电流自动调节,延长电机寿命。

6.高防护与抗干扰能力

通过IP67防护等级与Class A级EMC认证,耐受高压冲洗、极端温度及强电磁干扰,适用于食品加工、化工等严苛环境。

SANYO DENKI-769547 Product Overview

SANYO DENKI-769547 is a modular high-performance servo motor.As the backbone model of SANMOTION series under SANYO DENKI,it is specially designed for automated systems with flexible configuration and efficient drive.This product adopts a modular design,which can flexibly combine the motor body,encoder and cooling module to meet the customized needs of different application scenarios.The core functions cover dynamic torque control,multi-protocol communication,fault diagnosis and energy efficiency management,and the SANMOTION R series platform gives it excellent compatibility and scalability.In automation systems,SANYO DENKI-769547 is positioned as a”flexible drive solution”.Through the balance of modular architecture and high-performance parameters,it provides equipment manufacturers with fast adaptability from standard applications to non-standard designs,significantly reducing integration costs and cycles.

Main features and advantages

The technical characteristics and competitive advantages of SANYO DENKI-769547 are reflected in the following dimensions:

1.Modular design and fast adaptation

It supports free combination of motor body,encoder(optional 17-bit absolute value type/incremental type),cooling module(air-cooled/liquid cooling),and adapts to different heat dissipation needs such as machine tools and packaging machinery.

2.High-performance parameter balance

The rated torque covers 10-50Nm and the speed range is 0-6000rpm,taking into account the torque output and high-speed operation requirements in medium load scenarios.

3.Dynamic torque optimization(DTC)technology

Calculate the load inertia and friction coefficient in real time,adjust the current vector dynamically,and improve the system response speed by 30%.Supports dynamic torque compensation(DDC)to reduce mechanical impact.

4.Multi-protocol compatibility and flexible communication

Integrates three-in-one communication interfaces for EtherCAT,Profinet,and Modbus-TCP,and accesses mainstream automation systems without additional adapters.

5.Intelligent energy efficiency management

Dynamic current optimization(DCC)and regenerative energy feedback(REG)technology are used to achieve an overall energy saving efficiency of 25%.No-load current is automatically adjusted to extend the motor life.

6.High protection and anti-interference ability

Passed IP67 protection level and Class A EMC certification,it withstands high-pressure flushing,extreme temperatures and strong electromagnetic interference,and is suitable for harsh environments such as food processing and chemical industry.