描述

SANYO DENKI-769593产品概述

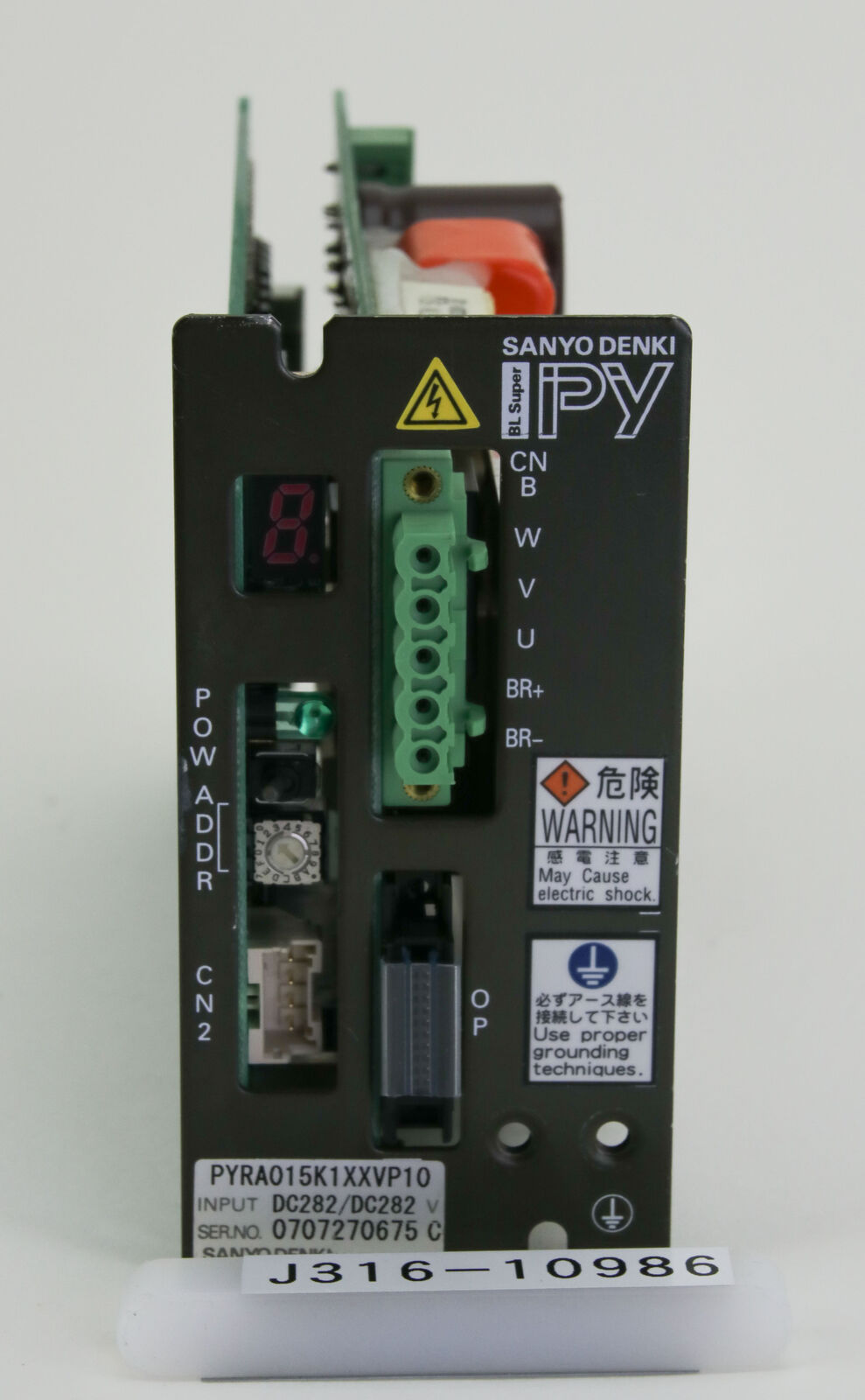

SANYO DENKI-769593是一款高性能交流伺服电机,作为SANYO DENKI旗下SANMOTION系列的高端型号,专为严苛工业环境下的高精度、高动态响应应用设计。该产品采用先进的矢量控制技术,结合高分辨率编码器与优化的磁路设计,实现精准扭矩输出与宽转速范围。核心功能包括动态扭矩补偿、自适应振动抑制、宽温域运行及实时状态监测,所属SANMOTION R系列平台使其在冶金、机床等高负载场景中具备卓越性能。在自动化系统中,SANYO DENKI-769593定位为“重载场景的核心动力单元”,通过提升功率密度与增强环境适应性,为设备提供稳定可靠的驱动力,同时优化生产效率与运行稳定性。

主要特点和优势

SANYO DENKI-769593的技术特性与竞争优势体现在以下维度:

1.高功率密度与宽转速范围

额定功率达5kW,峰值扭矩达80Nm,转速范围覆盖0-6000rpm,兼顾重负载启动与高速加工需求。

2.高精度控制与动态响应

搭载23位绝对式编码器(分辨率达8388608脉冲/转),结合高速反馈控制(响应频率2kHz),实现±0.001°的定位精度。

3.自适应振动抑制(AVS)技术

通过内置加速度传感器与自适应滤波器,实时抑制机械共振,降低振动幅度50%,提升加工表面质量。

4.强环境适应性设计

通过IP68防护等级与抗腐蚀涂层,耐受粉尘、油污及盐雾环境。工作温度范围扩展至-40℃至+85℃,适用于极寒或高温车间。

5.动态扭矩补偿(DTC)与能量优化

实时监测负载惯量并动态调整电流波形,减少启动冲击。再生能量回馈(REG)功能将制动能量转化为电能,节能效率达20%。

6.智能诊断与预测维护

集成状态监测系统(CMS),实时分析电流、温度、振动数据,通过AI算法预测轴承磨损与绝缘老化,提前6个月预警故障。

7.安全功能与冗余设计

符合ISO 13849-1 PL e安全等级,支持安全扭矩切断(STO)与安全速度监控(SSM)。可选双编码器冗余配置,提升系统可靠性。

8.灵活通信与快速调试

SANYO DENKI-769593 Product Overview

SANYO DENKI-769593 is a high-performance AC servo motor.As a high-end model of SANMOTION series under SANYO DENKI,it is designed for high-precision and high-dynamic response applications in harsh industrial environments.The product adopts advanced vector control technology,combined with high-resolution encoder and optimized magnetic circuit design,to achieve accurate torque output and wide speed range.The core functions include dynamic torque compensation,adaptive vibration suppression,wide temperature range operation and real-time state monitoring.The SANMOTION R series platform makes it excellent performance in high-load scenarios such as metallurgy and machine tools.In the automation system,SANYO DENKI-769593 is positioned as the”core power unit for heavy-duty scenarios”.By improving power density and enhancing environmental adaptability,it provides stable and reliable driving force for the equipment,while optimizing production efficiency and operating stability.

Main features and advantages

The technical characteristics and competitive advantages of SANYO DENKI-769593 are reflected in the following dimensions:

1.High power density and wide speed range

The rated power is up to 5kW,the peak torque is up to 80Nm,and the speed range covers 0-6000rpm,taking into account the needs of heavy load start-up and high-speed processing.

2.High-precision control and dynamic response

Equipped with a 23-bit absolute encoder(resolution up to 8388608 pulses/rpm),combined with high-speed feedback control(response frequency 2kHz),it achieves a positioning accuracy of±0.001°.

3.Adaptive vibration suppression(AVS)technology

Through the built-in acceleration sensor and adaptive filter,mechanical resonance is suppressed in real time,the vibration amplitude is reduced by 50%,and the processing surface quality is improved.

4.Strong environmental adaptability design

Through IP68 protection grade and corrosion-resistant coating,it is resistant to dust,oil and salt spray environments.The working temperature range is extended to-40℃to+85℃,suitable for extremely cold or high-temperature workshops.

5.Dynamic torque compensation(DTC)and energy optimization

Monitor load inertia in real time and adjust the current waveform dynamically to reduce start-up shock.The regeneration energy feedback(REG)function converts braking energy into electrical energy,saving energy up to 20%.

6.Intelligent diagnostics and prediction maintenance

Integrated status monitoring system(CMS)analyzes current,temperature and vibration data in real time,predicts bearing wear and insulation aging through AI algorithms,and warns of faults 6 months in advance.

7.Safety functions and redundant design

Comply with ISO 13849-1 PL e safety rating,supporting safe torque cut-off(STO)and safe speed monitoring(SSM).Optional dual encoder redundant configuration to improve system reliability.

8.Flexible communication and rapid debugging