描述

SANYO DENKI-770498产品概述

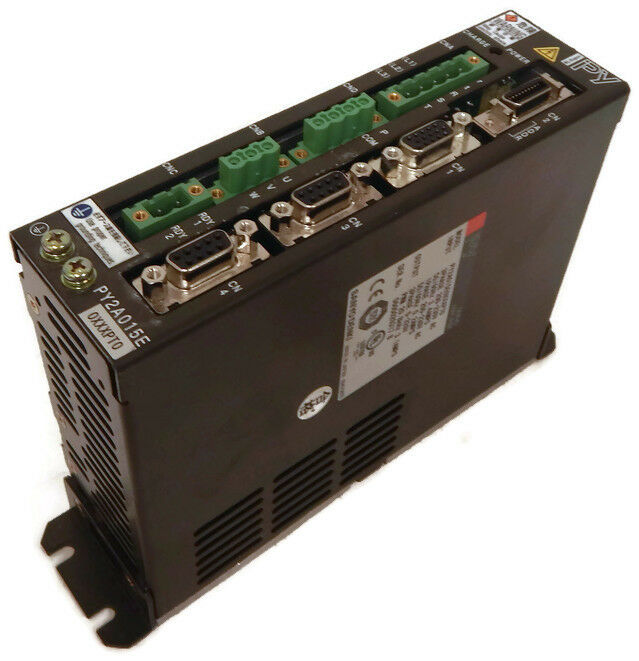

SANYO DENKI-770498是一款高性能伺服驱动器,作为SANYO DENKI旗下SANMOTION H系列的核心产品,专为复杂自动化系统的多轴协同控制与高压环境适应性设计。该产品集成先进矢量控制算法与高压驱动技术,核心功能涵盖多轴同步驱动、高压电源适配、实时性能优化及系统级故障诊断,所属智能驱动平台使其在自动化系统中定位为“核心控制单元”,通过优化电机驱动策略与系统资源调度,提升设备的动态响应与多轴协同效率,适用于高压工业设备、新能源系统、大型机械臂等高负载场景,显著降低能耗与调试复杂度,增强系统的集成度与可靠性。

主要特点和优势

SANYO DENKI-770498的技术特性与竞争优势体现在以下维度:

1.高压驱动与宽电压适配

支持AC 200-480V高压输入,电压波动容忍度±15%。采用先进矢量控制(Vector Control)与动态电流优化(DCC),适应工业电网不稳定环境。

2.多轴同步与高速通信

支持最多8轴同步控制,通信速率达10Mbps(EtherCAT/Profinet)。采用同步误差补偿(SEC)技术,多轴同步误差≤0.01ms。

3.高精度闭环驱动与自适应优化

内置高精度电流环控制(ACC)与速度环优化(SCO),闭环响应时间≤1ms。自适应参数整定(APT)自动适配电机特性,调试时间缩短80%。

4.强防护与恶劣环境适应性

防护等级IP65,耐受高温(85℃)、高湿度(95%RH)及振动(15G)。采用宽温域电子元件(-40℃至85℃运行),适用于户外或工业极端环境。

5.智能诊断与预防性维护

健康管理系统(HMS)实时监测驱动温度、电流谐波及IGBT状态。故障预测模型(FPM)提前预警过热、过载风险,维护成本降低40%。

6.高效节能与动态功率管理

动态功率分配(DPA)根据负载动态调节各轴功率,节能20%。采用低损耗IGBT模块,系统效率提升至98%。

7.开放式编程与灵活扩展

支持PLCopen运动控制标准,兼容第三方软件平台。自定义逻辑接口(CLI)允许用户编写高级控制算法,扩展性极强。

8.安全冗余与故障隔离

内置双重安全认证(Safety Certification EN 13849),支持STO(安全扭矩关断)。故障隔离设计确保单轴故障不影响系统运行。

SANYO DENKI-770498 Product Overview

SANYO DENKI-770498 is a high-performance servo driver.As the core product of SANMOTION H series under SANYO DENKI,it is designed for multi-axis collaborative control of complex automation systems and high-voltage environment adaptability.The product integrates advanced vector control algorithms and high-voltage driving technology.The core functions cover multi-axis synchronous driving,high-voltage power adaptation,real-time performance optimization and system-level fault diagnosis.The intelligent driving platform makes it positioned as a”core control unit”in the automation system.By optimizing motor driving strategies and system resource scheduling,the equipment’s dynamic response and multi-axis coordination efficiency are improved.It is suitable for high-voltage industrial equipment,new energy systems,large robotic arms and other high-load scenarios,significantly reducing energy consumption and debugging complexity,and enhancing the integration and reliability of the system.

Main features and advantages

The technical characteristics and competitive advantages of SANYO DENKI-770498 are reflected in the following dimensions:

1.High voltage drive and wide voltage adaptation

Supports AC 200-480V high-voltage input,voltage fluctuation tolerance±15%.Advanced vector control(Vector Control)and dynamic current optimization(DCC)are adopted to adapt to unstable environments of industrial power grids.

2.Multi-axis synchronization and high-speed communication

Supports up to 8-axis synchronous control,and the communication rate is up to 10Mbps(EtherCAT/Profinet).Synchronous error compensation(SEC)technology is used,and the multi-axis synchronization error is≤0.01ms.

3.High-precision closed-loop driving and adaptive optimization

Built-in high-precision current loop control(ACC)and speed loop optimization(SCO),with closed-loop response time≤1ms.Adaptive parameter tuning(APT)automatically adapts to the motor characteristics,and the debugging time is reduced by 80%.

4.Strong protection and harsh environmental adaptability

Protection level IP65,withstand high temperature(85℃),high humidity(95%RH)and vibration(15G).It uses wide temperature domain electronic components(operating from-40°C to 85°C),suitable for outdoor or industrial extreme environments.

5.Intelligent diagnostic and preventive maintenance

The health management system(HMS)monitors the driving temperature,current harmonics and IGBT status in real time.The Fault Prediction Model(FPM)has early warning of overheating and overload risks,and the maintenance cost is reduced by 40%.

6.High efficiency and energy saving and dynamic power management

Dynamic power distribution(DPA)dynamically adjusts the power of each axis according to the load,saving 20%energy.Using low-loss IGBT modules,the system efficiency has been improved to 98%.

7.Open programming and flexible expansion

Supports PLCopen motion control standard and is compatible with third-party software platforms.Custom Logical Interfaces(CLIs)allow users to write advanced control algorithms,which are extremely scalable.

8.Safety redundancy and fault isolation

Built-in dual safety certification(Safety Certification EN 13849)supports STO(safety torque shutdown).The fault isolation design ensures that single-axis failure does not affect system operation.