描述

SENTRY VREL-11减压阀产品简介

一、产品概述

SENTRY VREL-11减压阀是为现代发电厂水和蒸汽样品的化学分析设计的高压采样控制装置,专用于流速和压力的精确调节。其核心设计解决了高压减压过程中可能引发的流体组分分离和阀门腐蚀问题,广泛应用于电厂化学分析仪表的前端流量控制。

二、核心结构与工作原理

双管锥形杆设计

由两个精密焊接的不锈钢管组成,内部装配锥形杆组件。高压流体通过第一个杆后转向并流经第二个杆,形成分段降压路径。压降值由杆插入筒体的长度决定,层流条件下可平稳降压,减少组分解离。

可调节性与在线清洁

通过外部旋钮调整杆的位置,实现实时流量和压力控制,支持样品流动时动态调节。若发生堵塞,可缩回杆体,利用系统压力吹扫固体颗粒,实现原位清洁。

三、技术参数与性能

材质与耐压

接液部件采用316不锈钢,耐腐蚀性能优异。

额定压力:300°F时5000 psig(149°C时345 barg),临界发电厂应用可达783 psig(538 bar)。

温度与流量范围

适用温度≤200°C,流量调节范围0~3000 ml/min,可满足高温高压工况需求。

连接与接口

标准螺纹或焊接连接形式,兼容美标接口,适配电厂取样系统集成。

四、应用场景与优势

典型应用

电厂汽水取样装置高温架的减压控制,确保分析仪表进样流量稳定。

蒸汽和水样压力的精确调节,避免高压对采样系统的冲击。

技术优势

无磨损设计:层流降压避免阀门部件磨损,延长使用寿命。

防分离特性:分段压降减少流体组分解离,保障分析数据准确性。

操作便捷性:支持在线调节与清洁,无需拆卸采样管线。

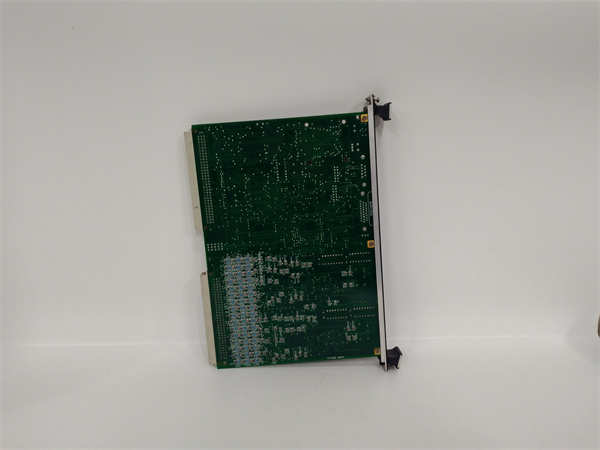

IS420PUAAH1A

IS420PUAAH1A

SENTRY VREL-11 Pressure Reducing Valve Product Introduction

I.Product Overview

SENTRY VREL-11 pressure reducing valve is a high-pressure sampling control device designed for chemical analysis of water and steam samples in modern power plants,dedicated to precise regulation of flow rate and pressure.Its core design solves the problems of fluid component separation and valve corrosion that may be caused during high-pressure pressure reduction,and is widely used in front-end flow control of chemical analysis instruments in power plants.

II.Core Structure and Working Principle

Double-tube tapered rod design

It consists of two precision-welded stainless steel tubes with a tapered rod assembly assembled inside.The high-pressure fluid turns after passing through the first rod and flows through the second rod,forming a segmented pressure reduction path.The pressure drop value is determined by the length of the rod inserted into the cylinder.Under laminar flow conditions,the pressure can be steadily reduced to reduce component separation.

Adjustability and online cleaning

The position of the rod is adjusted by an external knob to achieve real-time flow and pressure control,supporting dynamic adjustment during sample flow.If blockage occurs,the rod can be retracted and the solid particles can be purged using system pressure to achieve in-situ cleaning.

3.Technical parameters and performance

Material and pressure resistance

The wetted parts are made of 316 stainless steel,which has excellent corrosion resistance.

Rated pressure:5000 psig at 300°F(345 barg at 149°C),and can reach 783 psig(538 bar)for critical power plant applications.

Temperature and flow range

Applicable temperature≤200°C,flow adjustment range 0~3000 ml/min,which can meet the needs of high temperature and high pressure conditions.

Connection and interface

Standard threaded or welded connection form,compatible with American standard interface,suitable for power plant sampling system integration.

4.Application scenarios and advantages

Typical application

Decompression control of high temperature rack of steam and water sampling device in power plant to ensure stable sampling flow of analytical instrument.

Precise regulation of steam and water sample pressure to avoid high pressure impact on sampling system.

Technical advantages

Wear-free design:laminar pressure reduction avoids wear of valve components and extends service life.

Anti-separation characteristics:segmented pressure drop reduces fluid component separation and ensures the accuracy of analytical data.

Convenience of operation:supports online adjustment and cleaning without disassembling the sampling line.