描述

一、产品概述

STAHL ET-436-AT-R2-HB-TX-100GB-V是德国STAHL公司推出的工业级操作和监控面板,专为危险区域设计,适用于石油、天然气、化工、制药等行业的过程控制与设备监控。该产品属于PM ET-436 HMI系列,采用四核处理器和防爆结构,支持高分辨率显示与远程通信,提供灵活的系统集成能力。

二、核心功能与技术参数

1.硬件配置

显示与交互:

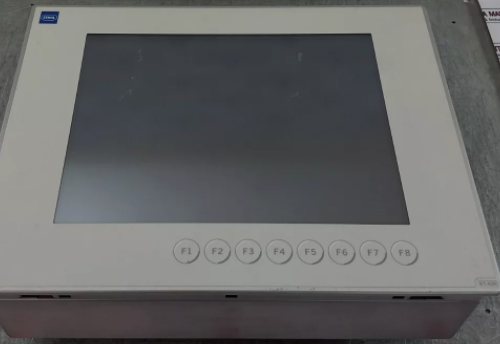

15英寸显示屏,分辨率1024×768像素(4:3比例),支持电阻式触摸屏,操作响应灵敏。

8个功能键:预设快捷操作,提升效率。

处理器与存储:

四核ATOM E3845处理器,搭配可扩展内存和固态硬盘,满足复杂数据处理需求。

通信接口:

支持10/100Base-TX以太网,通过CAT5电缆传输数据,最远距离100米。

2.安全与防护

防爆认证:

符合危险区域1、2、21、22及2区的防爆标准(ATEX/IECEx),无需额外外壳即可直接安装。

工业级耐用性:

采用坚固外壳设计,适应高温、高湿、振动等恶劣环境。

3.扩展功能

配件支持:

可选国家/地区键盘、RFID读卡器、条形码扫描仪等配件,扩展操作与数据采集能力。

集成选项:

支持与PLC、DCS等系统通过以太网无缝对接,适用于自动化产线监控。

三、典型应用场景

石油与天然气行业

井口设备监控、储罐压力与液位监测。

化工生产

反应釜温度控制、管道阀门状态实时显示。

制药与食品加工

清洁验证流程监控、生产线设备状态报警。

STAHL ET-436-AT-R2-HB-TX-100GB-V

STAHL ET-436-AT-R2-HB-TX-100GB-V

1.Product Overview

STAHL ET-436-AT-R2-HB-TX-100GB-V is an industrial-grade operation and monitoring panel launched by STAHL,Germany.It is specially designed for hazardous areas and is suitable for process control and equipment monitoring in oil,natural gas,chemical,pharmaceutical and other industries.This product belongs to the PM ET-436 HMI series,adopts a quad-core processor and explosion-proof structure,supports high-resolution display and remote communication,and provides flexible system integration capabilities.

2.Core functions and technical parameters

1.Hardware configuration

Display and interact:

15-inch display with a resolution of 1024×768 pixels(4:3 ratio),supports resistive touch screen,and is sensitive to operation.

8 function keys:Preset quick operation to improve efficiency.

Processor and storage:

Quad-core ATOM E3845 processor,paired with expandable memory and solid-state drive,meets complex data processing needs.

Communication interface:

Supports 10/100Base-TX Ethernet,transmits data through CAT5 cable,and has a maximum distance of 100 meters.

2.Safety and protection

Explosion-proof certification:

Comply with the explosion-proof standards(ATEX/IECEx)in hazardous areas 1,2,21,22 and 2,and can be installed directly without additional housing.

Industrial-grade durability:

It adopts a sturdy shell design to adapt to harsh environments such as high temperature,high humidity,and vibration.

3.Extended functions

Accessories support:

Optional accessories such as national keyboards,RFID card readers,barcode scanners,etc.,to expand operation and data collection capabilities.

Integration Options:

It supports seamless connection with PLC,DCS and other systems through Ethernet,and is suitable for automated production line monitoring.

3.Typical application scenarios

Oil and gas industry

Wellhead equipment monitoring,storage tank pressure and liquid level monitoring.

Chemical production

Reactor temperature control and pipeline valve status display in real time.

Pharmaceutical and food processing

Clean verification process monitoring,production line equipment status alarm.