描述

SUMITOMO MC-550 MCU是一款高性能伺服驱动器,专为工业自动化系统设计,集精确控制、紧凑设计与灵活扩展于一体。以下是其核心功能与技术参数的综合概述:

一、核心功能与性能

运动控制精度

-支持高精度定位与高速动态响应,适用于机器人、数控机床、包装设备等需要精确运动控制的场景。

-兼容绝对值和增量编码器,通过非易失性存储器保存系统参数(如绝对位置),确保断电后数据不丢失。

程序与指令集

-支持主程序(P000-P499)和子程序(P500-P999)结构,用户可通过编程实现复杂运动轨迹(如螺旋圆形插补、循环插补)。

-支持G代码指令(如G17-G22平面选择、G79程序结束),兼容CX Motion等运动控制软件。

插补与同步控制

-提供线性插补、圆形插补及螺旋插补功能,支持多轴协同运动(如两个轴圆形插补+一个轴线性插补)。

-通过环形插补实现高精度圆弧运动,适用于复杂几何路径加工。

二、技术参数与设计

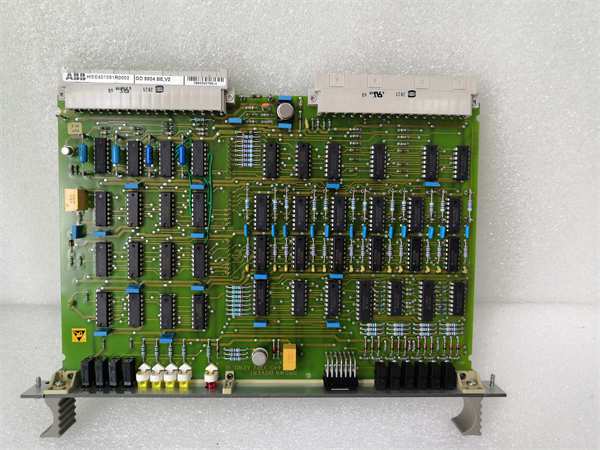

硬件设计

-紧凑型结构:体积小巧,节省安装空间,适合空间受限的工业设备。

-兼容性:专为SUMITOMO伺服电机设计,支持无缝配合与优化性能。

环境适应性

-工业级防护设计,适用于高温、高振动等复杂工况。

-支持宽电压输入范围(具体数值未公开),具备过压/过流保护功能。

通信与接口

-支持Modbus、CANopen等工业通信协议,可集成于主流PLC及DCS系统。

-提供数字量、模拟量输入输出接口,支持传感器与执行器的灵活连接。

三、应用场景

智能制造:机器人关节控制、CNC机床进给轴驱动、装配线定位系统。

包装行业:高速包装机的同步定位、标签贴附等高精度动作。

能源设备:风电叶片制造、光伏组件搬运等自动化产线。

科研与测试:精密实验平台的运动控制、动态负载模拟。

四、技术优势

高可靠性:冗余设计与非易失性存储确保长期稳定运行。

易用性:图形化配置工具简化参数设置,支持快速调试。

INSUMMCU2 MCU2A02V24

INSUMMCU2 MCU2A02V24

SUMITOMO MC-550 MCU is a high-performance servo drive designed for industrial automation systems,integrating precise control,compact design and flexible expansion.The following is a comprehensive overview of its core functions and technical parameters:

I.Core functions and performance

Motion control accuracy

-Supports high-precision positioning and high-speed dynamic response,suitable for scenarios requiring precise motion control such as robots,CNC machine tools,and packaging equipment.

-Compatible with absolute and incremental encoders,and saves system parameters(such as absolute position)through non-volatile memory to ensure that data is not lost after power failure.

Program and instruction set

-Supports main program(P000-P499)and subroutine(P500-P999)structures,and users can realize complex motion trajectories(such as spiral circular interpolation and cyclic interpolation)through programming.

-Supports G code instructions(such as G17-G22 plane selection,G79 program end),and is compatible with motion control software such as CX Motion.

Interpolation and synchronous control

-Provide linear interpolation,circular interpolation and spiral interpolation functions,support multi-axis coordinated motion(such as two-axis circular interpolation+one-axis linear interpolation).

-Achieve high-precision arc motion through circular interpolation,suitable for complex geometric path processing.

2.Technical parameters and design

Hardware design

-Compact structure:small size,saving installation space,suitable for space-constrained industrial equipment.

-Compatibility:specially designed for SUMITOMO servo motors,supporting seamless cooperation and optimized performance.

Environmental adaptability

-Industrial-grade protection design,suitable for complex working conditions such as high temperature and high vibration.

-Support wide voltage input range(specific valuesare not disclosed),with overvoltage/overcurrent protection function.

Communication and interface

-Support Modbus,CANopen and other industrial communication protocols,can be integrated into mainstream PLC and DCS systems.

-Provide digital and analog input and output interfaces,support flexible connection of sensors and actuators.

3.Application scenarios

Intelligent manufacturing:robot joint control,CNC machine tool feed axis drive,assembly line positioning system.

Packaging industry:high-precision actions such as synchronous positioning and label attachment of high-speed packaging machines.

Energy equipment:automated production lines such as wind turbine blade manufacturing and photovoltaic module handling.

Scientific research and testing:motion control and dynamic load simulation of precision experimental platforms.

4.Technical advantages

High reliability:Redundant design and non-volatile storage ensure long-term stable operation.

Ease of use:Graphical configuration tools simplify parameter settings and support fast debugging.