描述

SUMTAK IRH320-1000-203是一款高性能增量空心轴编码器,专为工业自动化和机器人应用设计,其核心功能与技术参数如下:

一、产品概述

该编码器采用中空轴设计,可轻松集成到机械臂、伺服系统等设备中,提供精确的位置和速度反馈。其坚固的结构和宽温工作范围(-40°C至+85°C)使其适用于恶劣工业环境。

二、核心特征

高分辨率

-支持高精度旋转编码,满足对位置反馈要求严苛的应用场景,如精密加工、运动控制等。

中空轴设计

-中空轴结构便于轴向安装,减少空间占用并提高设备集成效率。

耐用性与可靠性

-采用工业级材料制造,抗冲击、防振动,长期运行稳定性强。

低功耗

-优化电路设计,降低能耗,延长设备寿命并减少运行成本。

三、技术参数

工作温度范围:-40°C至+85°C

接口类型:增量输出(A/B相+Z相脉冲)

安装方式:轴向或法兰安装

四、应用场景

工业机器人

-为关节轴、旋转平台等提供精准角度反馈,提升机器人运动精度。

伺服系统

-监测电机转速与位置,实现闭环控制,优化设备性能。

自动化生产线

-用于传送带速度检测、分拣机械手定位等,提升生产效率。

精密加工设备

-应用于数控机床、激光切割机等,确保加工精度与重复性。

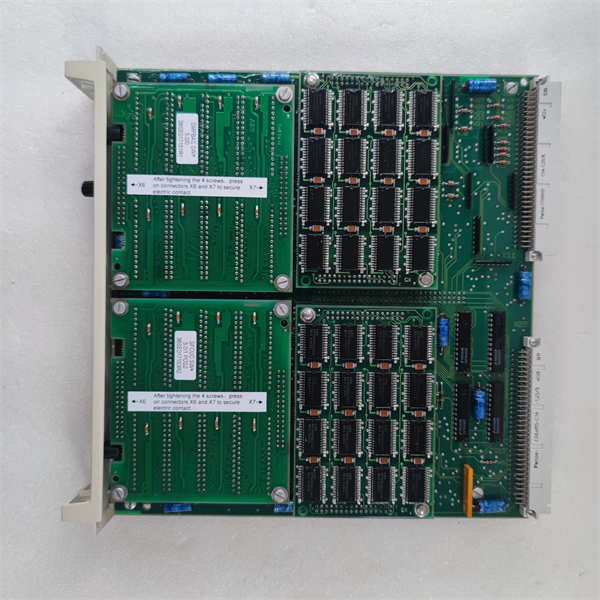

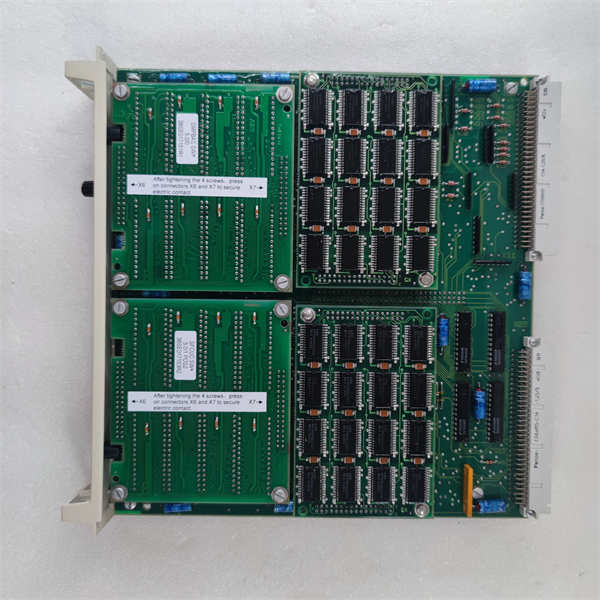

SUE3000 1VCR007346 G0032

SUE3000 1VCR007346 G0032

SUMTAK IRH320-1000-203 is a high-performance incremental hollow shaft encoder designed for industrial automation and robotics applications.Its core functions and technical parameters are as follows:

I.Product Overview

The encoder adopts a hollow shaft design and can be easily integrated into equipment such as robotic arms and servo systems to provide accurate position and speed feedback.Its rugged structure and wide operating temperature range(-40°C to+85°C)make it suitable for harsh industrial environments.

II.Core Features

High Resolution

-Supports high-precision rotary encoding to meet application scenarios with strict position feedback requirements,such as precision machining,motion control,etc.

Hollow Shaft Design

-The hollow shaft structure facilitates axial installation,reduces space occupancy and improves equipment integration efficiency.

Durability and Reliability

-Made of industrial-grade materials,it is shock-resistant and vibration-proof,and has strong long-term operating stability.

Low Power Consumption

-Optimize circuit design,reduce energy consumption,extend equipment life and reduce operating costs.

3.Technical parameters

Operating temperature range:-40°C to+85°C

Interface type:incremental output(A/B phase+Z phase pulse)

Installation method:axial or flange installation

4.Application scenarios

Industrial robots

-Provide accurate angle feedback for joint axes,rotating platforms,etc.to improve robot motion accuracy.

Servo system

-Monitor motor speed and position,achieve closed-loop control,and optimize equipment performance.

Automated production line

-Used for conveyor belt speed detection,sorting robot positioning,etc.to improve production efficiency.

Precision processing equipment

-Applied to CNC machine tools,laser cutting machines,etc.to ensure processing accuracy and repeatability.