描述

一、产品概述

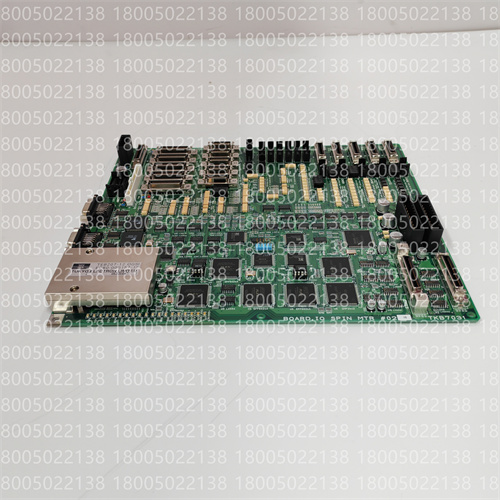

TEB207-12 OGSI EC80-000157-12是东京电子(Tokyo Electron Ltd.,TEL)推出的专用电子模块组件,主要用于半导体制造设备的核心控制子系统。该模块属于定制化设计,适用于真空蚀刻机、化学气相沉积(CVD)系统、物理气相沉积(PVD)设备及清洗机等场景。

二、核心功能与技术特性

功能定位

-推测用途:根据型号命名及行业经验,该模块可能承担以下功能之一:

-电源控制:调节设备供电稳定性,支持等离子体生成或真空系统运行;

-信号处理:负责工艺参数(如温度、压力)的采集与信号驱动;

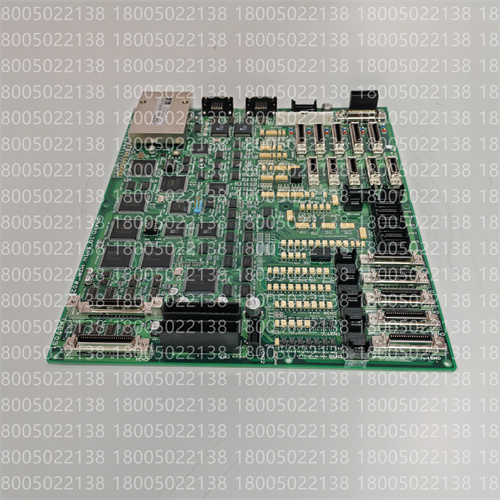

-IO接口管理:协调设备与上层控制系统(如PLC/DCS)的数据交互。

技术参数

-兼容平台:TEL Unity、Trias、Eagle等系列半导体设备;

-接口类型:可能集成RF匹配器控制、腔体状态监测等专用接口;

-环境适应性:工业级设计,支持半导体制造所需的高精度与抗干扰需求。

三、典型应用场景

半导体制造

-蚀刻设备:参与等离子源功率调节,确保蚀刻均匀性;

-CVD/PVD系统:监控气体流量、腔体真空度等关键参数。

维护与升级

-作为TEL设备的替换模块,用于故障修复或系统性能优化;

-支持与新型控制协议(如OPC UA)的集成,适配智能化产线改造。

1.Product Overview

TEB207-12 OGSI EC80-000157-12 is a dedicated electronic module component launched by Tokyo Electron Ltd.,which is mainly used for the core control subsystem of semiconductor manufacturing equipment.This module is a customized design and is suitable for vacuum etching machines,chemical vapor deposition(CVD)systems,physical vapor deposition(PVD)equipment and cleaning machines.

2.Core functions and technical characteristics

Functional positioning

-Speculative purpose:According to model naming and industry experience,this module may undertake one of the following functions:

-Power control:adjusts the power supply stability of the equipment and supports plasma generation or vacuum system operation;

-Signal processing:Responsible for the acquisition and signal driving of process parameters(such as temperature and pressure);

-IO interface management:coordinates the data interaction between the equipment and the upper control system(such as PLC/DCS).

Technical parameters

-Compatible platform:TEL Unity,Trias,Eagle and other series of semiconductor devices;

-Interface type:It may integrate dedicated interfaces such as RF matcher control,cavity status monitoring,etc.;

-Environmental adaptability:Industrial-grade design that supports the high precision and anti-interference requirements required for semiconductor manufacturing.

3.Typical application scenarios

Semiconductor manufacturing

-Etching equipment:participate in plasma source power regulation to ensure etching uniformity;

-CVD/PVD system:Monitor key parameters such as gas flow rate,cavity vacuum degree,etc.

Maintenance and Upgrade

-As a replacement module for TEL equipment,used for fault repair or system performance optimization;

-Supports integration with new control protocols(such as OPC UA)and adapts to intelligent production line transformation.