描述

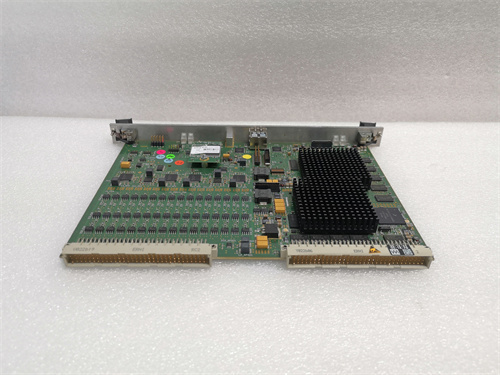

Terasaki ESM-103B是一款专为工业自动化设计的高性能控制板卡,广泛应用于机械控制、过程自动化及智能设备系统中。以下是其核心功能与技术特点的综合解析:

一、核心功能与性能

高速处理能力

基于高性能处理器和先进算法,ESM-103B实现快速数据处理与实时状态监测,支持复杂工业场景下的动态响应需求。

多功能控制选项

提供PID控制、逻辑控制、计数控制等模块化功能,用户可根据需求灵活配置,满足温度调节、运动控制、流程监控等多样化应用场景。

编程与开发灵活性

支持C/C++、PLC编程等开发工具,用户可通过简单编程实现复杂控制逻辑,提升系统智能化水平。

二、可靠性与防护特性

工业级设计

采用高品质元器件与严格生产工艺,适应恶劣工业环境(如高温、高湿、电磁干扰),防护等级达IP55。

多重保护机制

集成过流、过压、过热保护功能,有效防止硬件故障,保障设备安全运行。

三、兼容性与扩展性

通信协议支持

支持Modbus、Profibus、EtherNet/IP等主流工业协议,可无缝对接PLC、SCADA系统及智能设备。

模块化扩展接口

提供丰富输入输出端口(如数字量、模拟量接口),支持传感器、执行器等外设的灵活扩展。

四、典型应用场景

机械制造:伺服电机控制、装配线自动化、机器人运动轨迹规划。

能源电力:发电机保护、电网参数监测、变频器协同控制。

过程工业:温度闭环控制、流量调节、压力报警系统。

五、技术优势总结

模块化设计:便于维护与功能升级。

低延迟响应:适用于高速动态控制需求。

宽电压输入:支持24V DC±10%供电范围。

Terasaki ESM-103B is a high-performance control board designed for industrial automation,widely used in mechanical control,process automation and intelligent equipment systems.The following is a comprehensive analysis of its core functions and technical features:

1.Core functions and performance

High-speed processing capability

Based on high-performance processors and advanced algorithms,ESM-103B achieves fast data processing and real-time status monitoring,and supports dynamic response requirements in complex industrial scenarios.

Multi-function control options

Provides modular functions such as PID control,logic control,and counting control.Users can flexibly configure according to needs to meet diverse application scenarios such as temperature regulation,motion control,and process monitoring.

Programming and development flexibility

Supports development tools such as C/C++and PLC programming.Users can implement complex control logic through simple programming to improve the intelligence level of the system.

2.Reliability and protection features

Industrial-grade design

Adopts high-quality components and strict production processes to adapt to harsh industrial environments(such as high temperature,high humidity,and electromagnetic interference),and the protection level reaches IP55.

Multiple protection mechanisms

Integrated overcurrent,overvoltage,and overheating protection functions effectively prevent hardware failures and ensure safe operation of equipment.

3.Compatibility and scalability

Communication protocol support

Supports mainstream industrial protocols such as Modbus,Profibus,EtherNet/IP,and can seamlessly connect to PLC,SCADA systems and intelligent devices.

Modular expansion interface

Provides a variety of input and output ports(such as digital and analog interfaces)to support flexible expansion of peripherals such as sensors and actuators.

4.Typical application scenarios

Mechanical manufacturing:servo motor control,assembly line automation,robot motion trajectory planning.

Energy and power:generator protection,power grid parameter monitoring,inverter collaborative control.

Process industry:temperature closed-loop control,flow regulation,pressure alarm system.

5.Summary of technical advantages

Modular design:easy to maintain and upgrade functions.

Low latency response:suitable for high-speed dynamic control requirements.

Wide voltage input:supports 24V DC±10%power supply range.