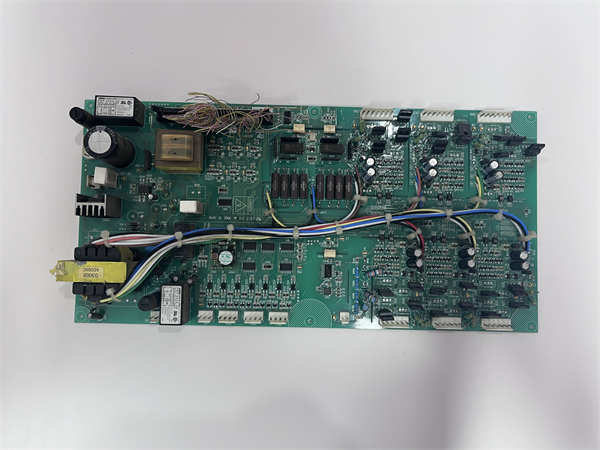

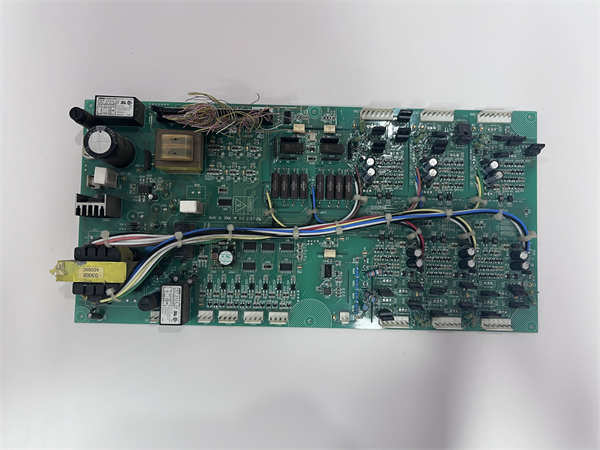

描述

TOSHIBA 2N3A8130-A是东芝(TOSHIBA)旗下的一款工业自动化PLC模块,专为高可靠性与复杂控制系统设计,广泛应用于能源、制造、化工等领域。以下是其核心功能与技术特点的综合分析:

一、产品概述

2N3A8130-A是东芝2N系列PLC模块的典型代表,属于输入/输出扩展模块,支持多种信号类型(如数字量、模拟量)的采集与控制。其设计遵循工业级标准,具备高抗干扰能力,适用于严苛的电磁环境。

二、技术特点

扩展能力

-支持多类型信号接口,可灵活配置为数字量输入/输出或模拟量输入模块,满足不同工业场景的多样化需求。

-通过与主控制器(如东芝2N系列PLC)协同工作,实现大规模系统的分布式控制。

通信协议兼容性

-支持Modbus、Profibus等工业通信协议,可无缝集成至主流DCS(分布式控制系统)或SCADA系统,提升系统互联互通性。

安全与稳定性

-采用模块化设计,支持热插拔维护,减少系统停机时间。

-内置自诊断功能,实时监控模块状态,预防潜在故障。

三、应用场景

能源行业

-用于发电厂、变电站的设备监控与保护,如开关状态采集、温度/压力参数监测。

-集成于DCS系统,实现电力系统的高效稳定运行。

制造领域

-在化工、冶金等流程工业中,用于工艺参数(如流量、液位)的实时采集与控制,优化生产效率。

-应用于数控机床(CNC)的伺服控制,提升加工精度。

基础设施

-适用于电梯、停车场、水处理系统的自动化控制,保障公共设施的可靠运行。

ARND-3119 A6 2N3A3119-B

ARND-3119 A6 2N3A3119-B

TOSHIBA 2N3A8130-A is an industrial automation PLC module under TOSHIBA,designed for high reliability and complex control systems,and widely used in energy,manufacturing,chemical industry and other fields.The following is a comprehensive analysis of its core functions and technical features:

1.Product Overview

2N3A8130-A is a typical representative of Toshiba’s 2N series PLC modules.It is an input/output expansion module that supports the acquisition and control of multiple signal types(such as digital and analog).Its design follows industrial standards,has high anti-interference ability,and is suitable for harsh electromagnetic environments.

2.Technical Features

Expansion Capability

-Supports multiple types of signal interfaces and can be flexibly configured as digital input/output or analog input modules to meet the diverse needs of different industrial scenarios.

-Realize distributed control of large-scale systems by working in conjunction with the main controller(such as Toshiba 2N series PLC).

Communication protocol compatibility

-Supports industrial communication protocols such as Modbus and Profibus,and can be seamlessly integrated into mainstream DCS(distributed control systems)or SCADA systems to improve system interoperability.

Safety and stability

-Adopts modular design,supports hot-swap maintenance,and reduces system downtime.

-Built-in self-diagnosis function,real-time monitoring of module status,and prevention of potential failures.

III.Application scenarios

Energy industry

-Used for equipment monitoring and protection in power plants and substations,such as switch status acquisition and temperature/pressure parameter monitoring.

-Integrated in the DCS system to achieve efficient and stable operation of the power system.

Manufacturing field

-In process industries such as chemical and metallurgical industries,it is used for real-time acquisition and control of process parameters(such as flow and liquid level)to optimize production efficiency.

-Applied to servo control of CNC machine tools(CNC)to improve processing accuracy.

Infrastructure

-Suitable for automated control of elevators,parking lots,and water treatment systems to ensure the reliable operation of public facilities.