描述

一、产品定位与核心功能

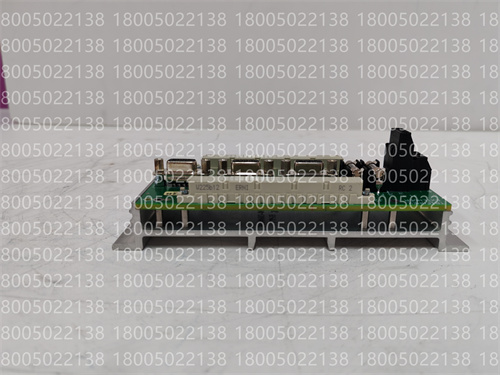

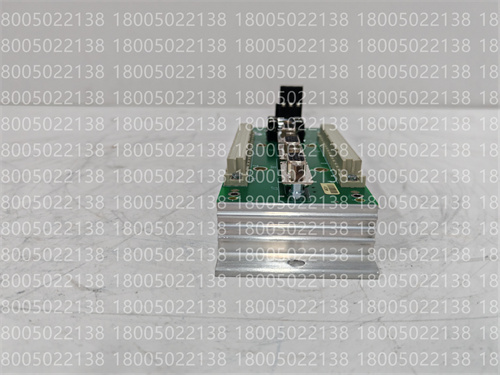

模块类型

-通信接口模块(TCMI):作为Triconex系统与外部网络的桥梁,支持容错以太网(FTE)和增强通用控制网络(EUCN)协议,实现双向数据传输。

-处理器模块:部分文献描述其具备三重冗余(TMR)计算能力,适用于复杂控制任务(如实时数据采集与逻辑决策)。

核心功能

-数据映射与转换:将Triconex内存表数据转换为EUCN标签格式,支持远程监控与报警处理;

-冗余通信:通过双端口配置实现高可用性,兼容Triconex TRICON安全管理系统;

-协议支持:Modbus、Ethernet/IP、Profibus DP等,适配多品牌设备接入。

二、关键技术参数

|项目|参数/功能|

|冗余设计|三重模块化冗余(TMR),支持热插拔|

|工作电压|24V DC(部分文献提及220V AC选项)|

|环境温度|-20°C至+60°C|

|安全认证|SIL 3(IEC 61508/ISA 84.00.01)|

|通信接口|以太网(10/100Mbps)、光纤(可选)|

|输入/输出|依子型号不同,涵盖DI/DO/AO通道|

三、典型应用场景

石油化工

-分布式控制系统(DCS)与现场设备(如阀门、泵组)的数据交互,支持远程监控与故障诊断。

电力能源

-汽轮机控制系统的实时信号传输(如温度、转速监测)。

制药与食品

-无菌灌装线的精准控制,满足GMP标准对数据追溯的要求。

1.Product positioning and core functions

Module Type

-Communication Interface Module(TCMI):As a bridge between the Triconex system and external network,it supports fault-tolerant Ethernet(FTE)and enhanced universal control network(EUCN)protocols to realize bidirectional data transmission.

-Processor Module:Some documents describe it as having triple redundancy(TMR)computing capabilities,suitable for complex control tasks(such as real-time data acquisition and logical decision-making).

Core functions

-Data mapping and conversion:convert Triconex memory table data into EUCN tag format,supporting remote monitoring and alarm processing;

-Redundant communication:high availability through dual-port configuration,compatible with Triconex TRICON security management system;

-Protocol support:Modbus,Ethernet/IP,Profibus DP,etc.,adapted to access multiple brands of equipment.

2.Key technical parameters

|Project|Parameters/Functions|

|Redundant Design|Triple Modular Redundancy(TMR),Hot Swap|

|Operating voltage|24V DC(some literature mentions the 220V AC option)|

|Ambient temperature|-20°C to+60°C|

|Safety Certification|SIL 3(IEC 61508/ISA 84.00.01)|

|Communication interface|Ethernet(10/100Mbps),fiber(optional)|

|Input/Output|DI/DO/AO channels are covered by different sub-model|

3.Typical application scenarios

Petrochemical

-Data interaction between distributed control system(DCS)and field equipment(such as valves and pump groups),supporting remote monitoring and fault diagnosis.

Electricity

-Real-time signal transmission(such as temperature and speed monitoring)of the turbine control system.

Pharmaceuticals and Food

-Accurate control of sterile filling lines meets the requirements of GMP standards for data traceability.