描述

一、产品定位与核心功能

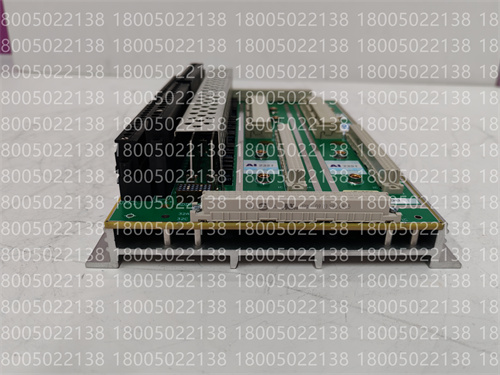

模块类型

-模拟输入模块(AI):负责采集温度、压力、流量等传感器信号,并转换为系统可处理的数字信号。

-集成安全诊断:支持输出表决器诊断(OVD),实时监测信号状态并记录故障。

核心功能

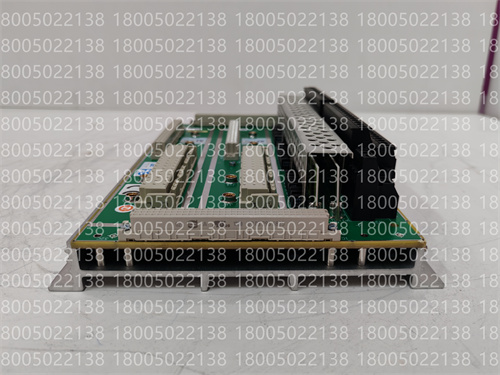

-信号处理:支持4-20mA、0-5V等工业标准信号输入,具备信号调理与隔离功能;

-冗余设计:双通道架构确保单点故障下系统持续运行,适用于SIL 3安全等级场景;

-通信支持:兼容Triconex系统总线协议,可集成至EUCN(增强通用控制网络)。

二、关键技术参数

|项目|参数/功能|

|输入通道|8路隔离通道(依子型号可能不同)|

|精度|±0.1%FSR(满量程)|

|响应时间|<10ms|

|安全认证|IEC 61508,ISA 84.00.01(SIL 3)|

|工作环境|-20°C~+70°C,IP20防护|

三、典型应用场景

化工与石油

-反应釜温度监测、管道压力控制,支持紧急停车系统(ESD)触发。

电力与能源

-锅炉水位监控、燃气轮机振动信号采集,保障设备安全运行。

智能制造

-产线自动化中的闭环控制(如注塑机压力调节)。

1.Product positioning and core functions

Module Type

-Analog input module(AI):Responsible for collecting sensor signals such as temperature,pressure,flow,etc.and converting them into digital signals that the system can process.

-Integrated safety diagnostics:Supports output voting device diagnostics(OVD),monitors signal status in real time and records faults.

Core functions

-Signal processing:supports industrial standard signal input such as 4-20mA,0-5V,and has signal conditioning and isolation functions;

-Redundant design:The dual-channel architecture ensures continuous operation of the system under single point of failure,suitable for SIL 3 safety level scenarios;

-Communication support:Compatible with Triconex system bus protocol,can be integrated into EUCN(enhanced universal control network).

2.Key technical parameters

|Project|Parameters/Functions|

|Input Channel|8 Isolated Channels(may vary depending on sub-model)|

|Accuracy|±0.1%FSR(full scale)|

|Response time|<10ms|

|Safety Certification|IEC 61508,ISA 84.00.01(SIL 3)|

|Working environment|-20°C~+70°C,IP20 protection|

3.Typical application scenarios

Chemical and Petroleum

-Reactor temperature monitoring,pipeline pressure control,support emergency parking system(ESD)triggering.

Electricity and Energy

-Boiler water level monitoring and gas turbine vibration signal collection to ensure the safe operation of the equipment.

Intelligent manufacturing

-Closed-loop control in production line automation(such as injection molding machine pressure regulation).