描述

一、核心功能与定位

安全完整性等级(SIL):

符合IEC 61508 SIL 3和TÜV功能安全认证,适用于安全仪表系统(SIS),可承担安全关键功能(如紧急停车、火灾报警、气体泄漏检测)。

采用三重模块化冗余(TMR)架构,通过三取二表决机制消除单点故障影响,确保系统可用性≥99.999%。

数字量输入处理:

接收现场设备(如压力开关、温度开关、限位开关、紧急按钮)的干接点或湿接点信号,转换为Triconex系统可识别的数字信号。

支持24V DC或120V AC(需确认具体型号)输入信号,适应不同电压等级的现场设备。

二、技术规格

参数类别详细规格

输入通道数16路(每路独立隔离,通道间无干扰)

输入类型干接点(无源触点)或湿接点(有源触点,需外部供电)

输入电压范围干接点:0V~30V DC(兼容24V DC标准);湿接点:需匹配外部电源(如120V AC)

输入电流干接点:≤1mA(典型);湿接点:根据外部电源配置

响应时间≤10ms(从信号变化到系统识别)

隔离方式通道间光电隔离,模块与总线间变压器隔离,耐压≥1500V AC

诊断功能-通道级开路/短路检测

-模块级电源、通信、硬件故障自诊断

-实时上报故障代码至控制器

环境适应性-工作温度:-20℃~+70℃

-存储温度:-40℃~+85℃

-湿度:5%~95%RH(无凝露)

-防护等级:IP20(机柜安装)

认证标准-IEC 61508 SIL 3

-TÜV Rheinland

-ATEX/IECEx(防爆认证,可选)

-UL/cUL

-FM(火灾报警应用)

三、硬件特性

模块设计:

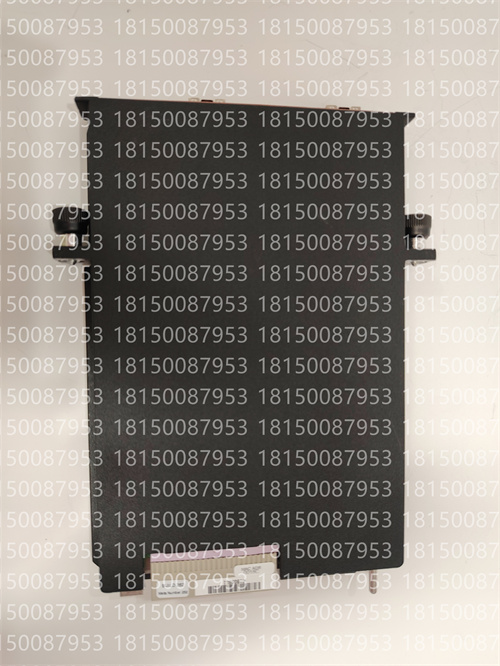

紧凑型DIN导轨安装,尺寸约112mm(高)×25mm(宽)×120mm(深),节省机柜空间。

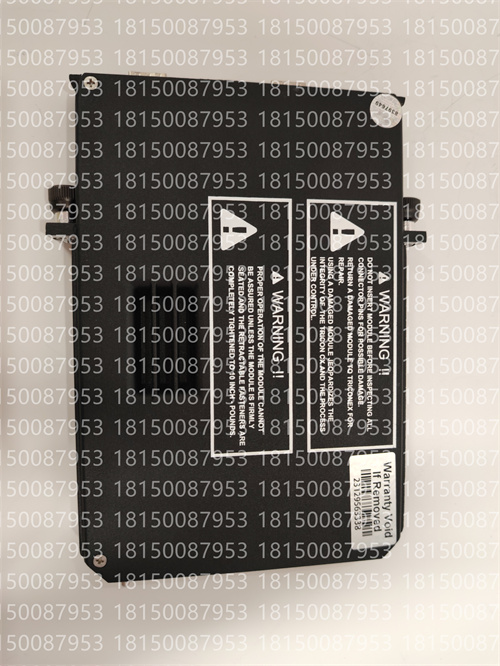

前面板指示灯:显示模块状态(运行/故障)和通道状态(正常/报警),便于快速故障定位。

可插拔端子排:支持热插拔,维护时无需断电,减少停机时间。

冗余与容错:

TMR架构:每个输入通道由三个独立通道同时处理,通过三取二表决输出结果,确保单通道故障不影响系统安全。

自动同步:模块与控制器之间实时同步数据,避免数据丢失或不一致。

四、应用场景

紧急停车系统(ESD):

接收工艺参数超限信号(如高压、高温、低液位),触发联锁停车,防止事故扩大。

示例:在炼油厂催化裂化装置中,DI3301监测反应器压力开关,压力超限时立即切断进料。

火灾与气体检测(F&G):

连接火焰探测器、可燃气体传感器,实时监测火灾或泄漏风险,启动报警或灭火程序。

示例:在海上平台中,DI3301接收甲烷探测器信号,浓度超标时触发ESD停车和消防系统。

关键设备保护:

监控大型旋转机械(如压缩机、涡轮机)的振动、轴位移信号,超限时触发安全停机。

示例:在天然气长输管道压气站中,DI3301接收压缩机振动开关信号,防止设备损坏。

1.Core functions and positioning

Safety integrity level(SIL):

Complies with IEC 61508 SIL 3 and TÜV functional safety certification,suitable for safety instrumented systems(SIS),and can undertake safety-critical functions(such as emergency stop,fire alarm,gas leak detection).

Adopting triple modular redundant(TMR)architecture,the influence of single point failure is eliminated through the two-out-of-three voting mechanism to ensure system availability≥99.999%.

Digital input processing:

Receive dry contact or wet contact signals from field devices(such as pressure switches,temperature switches,limit switches,emergency buttons)and convert them into digital signals that can be recognized by the Triconex system.

Supports 24V DC or 120V AC(specific model needs to be confirmed)input signals to adapt to field devices of different voltage levels.

2.Technical Specifications

Parameter Category Detailed Specifications

Number of Input Channels 16(Each channel is independently isolated,and there is no interference between channels)

Input Type Dry Contact(Passive Contact)or Wet Contact(Active Contact,External Power Supply Required)

Input Voltage Range Dry Contact:0V~30V DC(Compatible with 24V DC Standard);Wet Contact:Need to match external power supply(such as 120V AC)

Input Current Dry Contact:≤1mA(typical);Wet Contact:According to external power supply configuration

Response Time≤10ms(from signal change to system recognition)

Isolation Mode Optical isolation between channels,transformer isolation between module and bus,withstand voltage≥1500V AC

Diagnostic Function-Channel level Open/Short Circuit Detection

-Module Level Power,Communication,Hardware Fault Self-diagnosis

-Real-time Reporting Fault Code to Controller

Environmental Adaptability-Operating Temperature:-20℃~+70℃

-Storage Temperature:-40℃~+85℃

-Humidity:5%~95%RH(no condensation)

-Protection level:IP20(cabinet installation)

Certification standards-IEC 61508 SIL 3

-TÜV Rheinland

-ATEX/IECEx(explosion-proof certification,optional)

-UL/cUL

-FM(fire alarm application)

III.Hardware features

Module design:

Compact DIN rail installation,size is about 112mm(height)×25mm(width)×120mm(depth),saving cabinet space.

Front panel indicator:Display module status(running/fault)and channel status(normal/alarm)for fast fault location.

Pluggable terminal block:supports hot swapping,no need to power off during maintenance,reducing downtime.

Redundancy and fault tolerance:

TMR architecture:Each input channel is processed by three independent channels at the same time,and the output result is output through three-out-of-two voting,ensuring that a single channel failure does not affect system safety.

Automatic synchronization:Data is synchronized between the module and the controller in real time to avoid data loss or inconsistency.

IV.Application scenarios

Emergency shutdown system(ESD):

Receive process parameter over-limit signals(such as high pressure,high temperature,low liquid level),trigger interlock shutdown,and prevent accidents from expanding.

Example:In the catalytic cracking unit of the refinery,DI3301 monitors the reactor pressure switch and immediately cuts off the feed when the pressure exceeds the limit.

Fire and gas detection(F&G):

Connect flame detectors and combustible gas sensors to monitor fire or leakage risks in real time and start alarm or fire extinguishing procedures.

Example:In an offshore platform,DI3301 receives methane detector signals and triggers ESD shutdown and fire fighting systems when the concentration exceeds the standard.

Key equipment protection:

Monitor the vibration and shaft displacement signals of large rotating machinery(such as compressors and turbines),and trigger safe shutdown when the limit is exceeded.

Example:In a natural gas long-distance pipeline compressor station,DI3301 receives compressor vibration switch signals to prevent equipment damage.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101