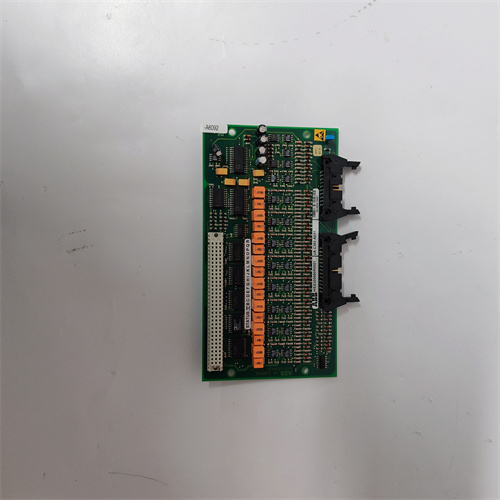

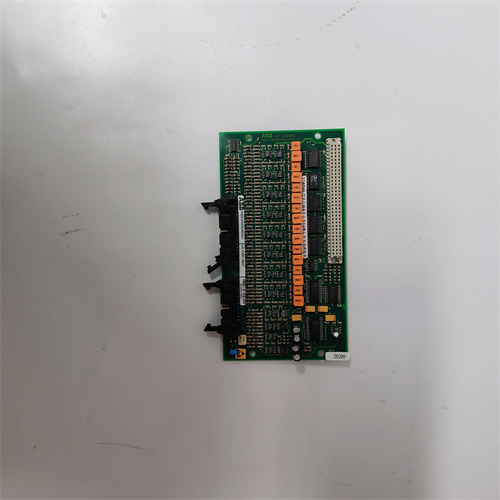

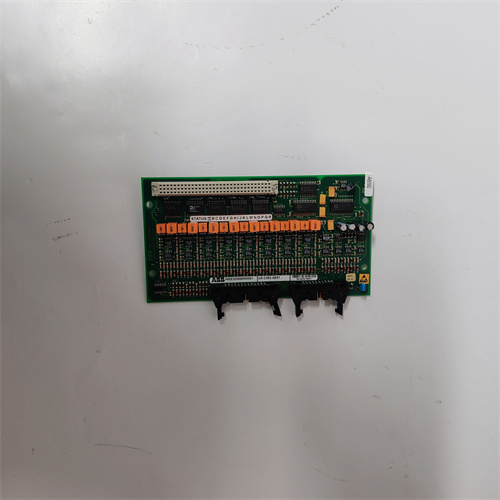

描述

UAC383AE01 HIEE300890R0001分散控制系统是ABB公司推出的一款高性能工业自动化控制系统,专为离散自动化和运动控制设计,广泛应用于化工、电力、制造等工业领域。以下是其核心功能与技术特性概述:

1.核心功能与架构

分散控制与模块化设计:

系统采用分散式控制结构,将控制功能分配到多个节点,提高系统稳定性和可靠性。模块化设计允许用户根据需求灵活扩展或替换功能模块,支持从基础配置到复杂系统的无缝升级。

高性能处理能力:

集成高性能处理器、内存和输入输出接口,实现工业过程的精确控制。支持多任务并行处理,满足高实时性要求。

多协议通信:

支持Modbus、ProfiBus、Ethernet等工业通信协议,兼容主流设备与系统,便于数据集成与协同工作。

2.技术参数与性能

信号处理与隔离保护:

每个输入输出通道配备独立电流隔离和限流保护,防止单点故障影响整体系统稳定性。支持线路监测DI、SOE和高电流选项,减少对外部设备依赖。

环境适应性:

工作温度范围-40°C至+70°C,防护等级IP20,适用于极端工业环境(如风电、化工现场)。

实时数据采集:

采用并行采样技术,支持微秒级采样周期,适用于高压输电、快速定位等对响应速度要求极高的场景。

3.应用领域

化工与能源:

监控反应釜温度、压力等参数,优化工艺流程。

电力系统:

控制发电机启停、变压器保护及配电网络管理。

制造业:

集成于生产线,实现设备联动与质量检测。

风电行业:

作为变桨系统核心组件,管理风机叶片角度与紧急顺桨动作。

UAC383AE01 HIEE300890R0001 Distributed Control System is a high-performance industrial automation control system launched by ABB,designed for discrete automation and motion control,and widely used in chemical,power,manufacturing and other industrial fields.The following is an overview of its core functions and technical features:

1.Core functions and architecture

Distributed control and modular design:

The system adopts a distributed control structure to distribute control functions to multiple nodes to improve system stability and reliability.The modular design allows users to flexibly expand or replace functional modules according to needs,supporting seamless upgrades from basic configuration to complex systems.

High-performance processing capability:

Integrates high-performance processors,memory and input and output interfaces to achieve precise control of industrial processes.Supports multi-task parallel processing to meet high real-time requirements.

Multi-protocol communication:

Supports industrial communication protocols such as Modbus,ProfiBus,Ethernet,etc.,compatible with mainstream equipment and systems,and facilitates data integration and collaborative work.

2.Technical parameters and performance

Signal processing and isolation protection:

Each input and output channel is equipped with independent current isolation and current limiting protection to prevent single point failures from affecting the overall system stability.Supports line monitoring DI,SOE and high current options to reduce dependence on external devices.

Environmental adaptability:

The operating temperature range is-40°C to+70°C,and the protection level is IP20,which is suitable for extreme industrial environments(such as wind power and chemical sites).

Real-time data acquisition:

Using parallel sampling technology,it supports microsecond sampling cycles and is suitable for scenarios with extremely high response speed requirements such as high-voltage power transmission and rapid positioning.

3.Application areas

Chemical and energy:

Monitor parameters such as reactor temperature and pressure to optimize process flow.

Power system:

Control generator start and stop,transformer protection and distribution network management.

Manufacturing industry:

Integrated in the production line to achieve equipment linkage and quality inspection.

Wind power industry:

As the core component of the variable pitch system,it manages the angle of wind turbine blades and emergency feathering action.