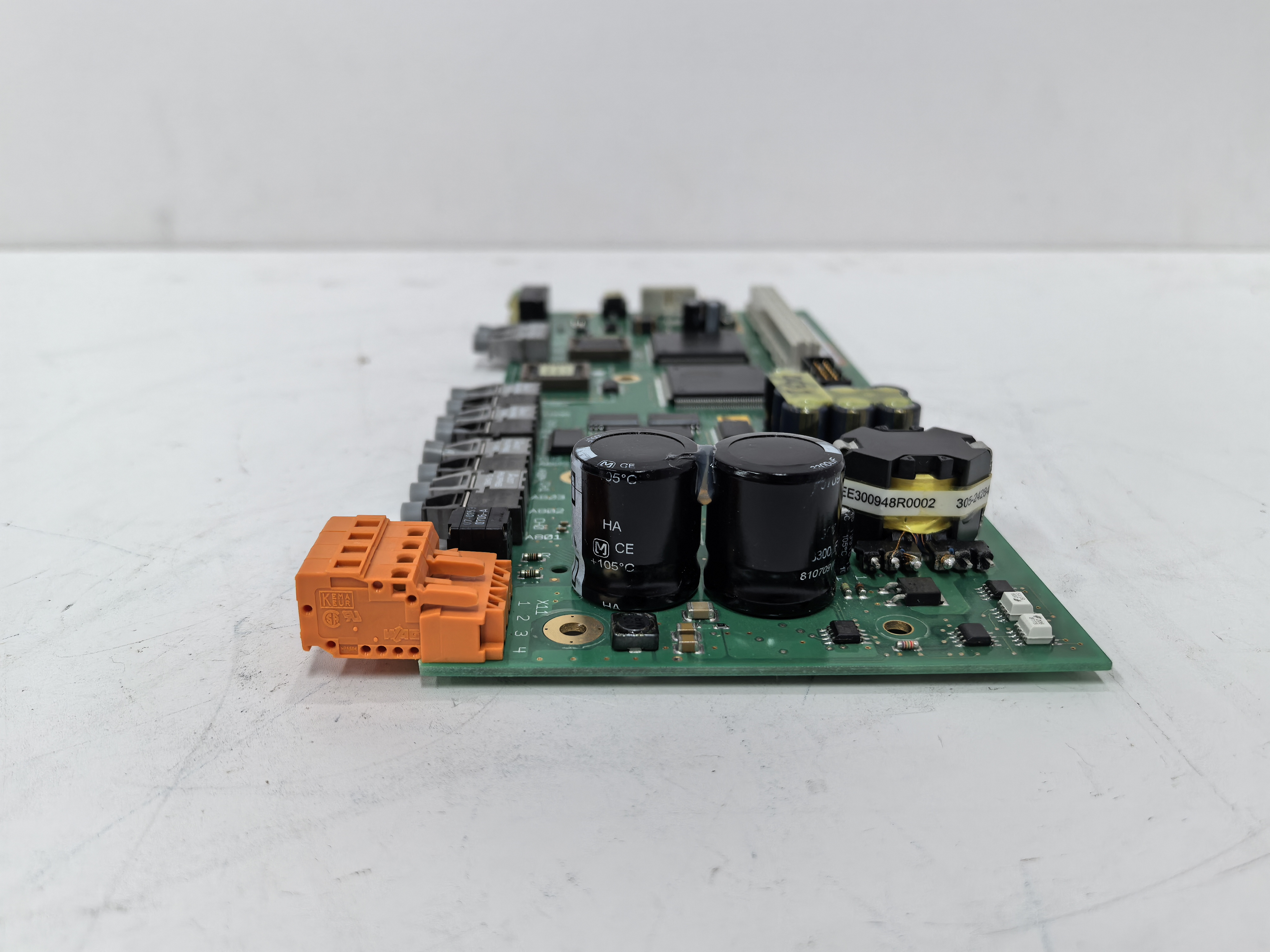

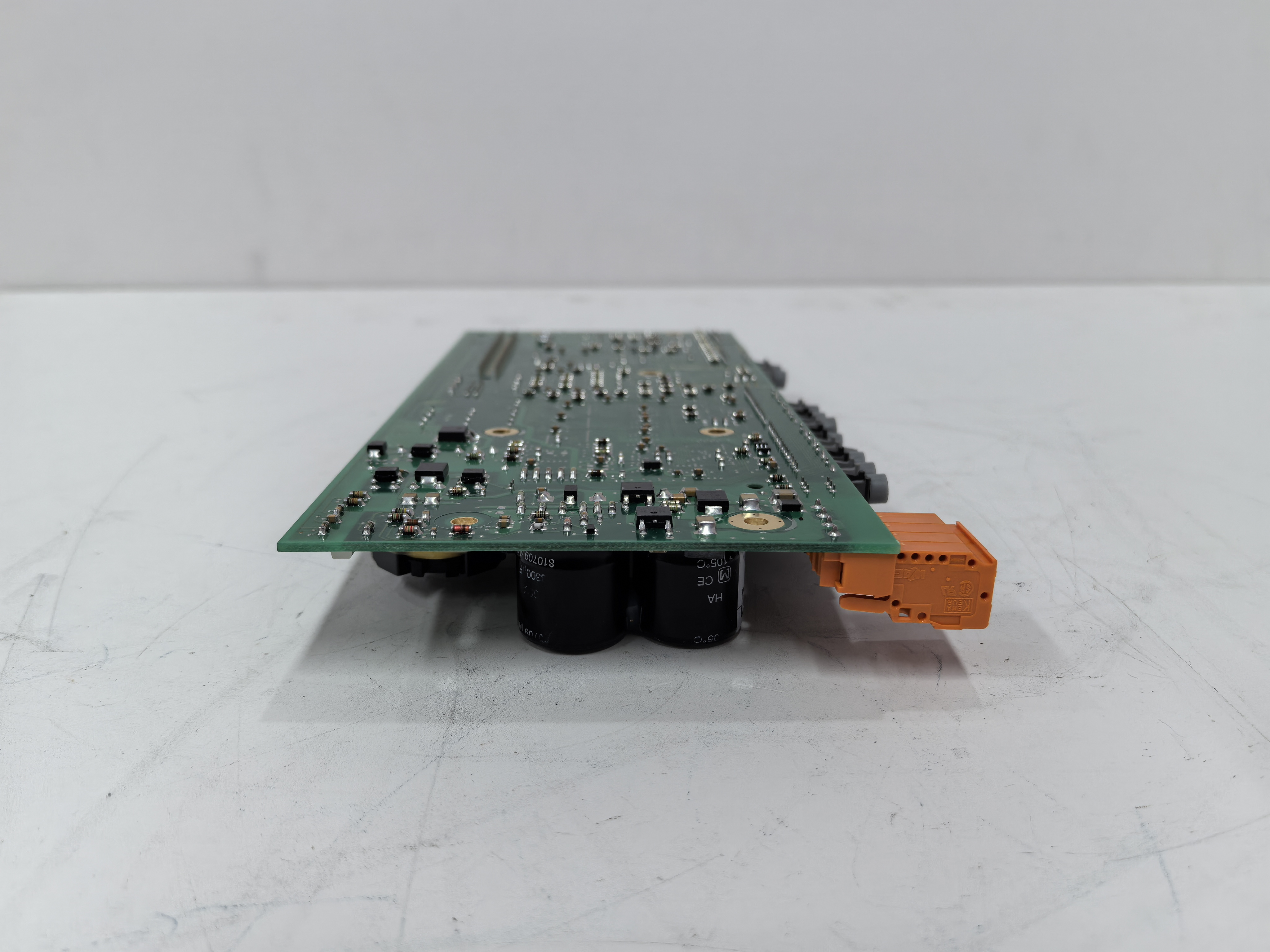

描述

VARIAN 100010077-06直流调速器控制板是一款专为直流电机速度控制设计的电子设备,广泛应用于工业、新能源、交通运输等多个领域。以下是其核心功能与技术特点的综合解析:

一、核心功能与技术特点

电源管理

集成高效电源管理电路,可稳定输出电压并防止过电流、过压等问题,确保电机和系统运行安全。

PWM调速控制

采用脉冲宽度调制(PWM)技术,通过调节脉冲宽度动态调整电机平均电压,实现宽范围调速(如低速平稳、高速高效),响应速度快且控制精度高。

速度反馈与闭环控制

配备编码器或霍尔效应传感器接口,实时采集电机转速信号并形成闭环反馈,确保实际转速与设定值一致。

保护功能

具有过流、过压、过热等多重保护机制,可自动切断电源或触发报警,避免设备损坏。

通信与扩展性

支持RS-485、以太网等通信协议,可连接上位机或PLC实现远程控制和数据交互;部分型号提供可编程接口,允许用户自定义参数设置。

可调参数

用户可通过配置工具调整加减速时间、电流限值等参数,适应不同电机特性及应用场景需求。

二、应用场景

工业自动化

-控制生产线上的输送带、风机、泵等机械设备,优化生产效率与精度。

新能源领域

-在太阳能光伏、风力发电系统中调节电机转速,实现最大功率追踪(MPPT)及能量转换效率优化。

交通运输

-应用于电动汽车、电动自行车等交通工具,精准控制电机扭矩与行驶性能。

家用电器与机器人技术

-用于电动工具、搅拌器等家用设备,以及机器人关节运动控制,提升操作灵活性。

医疗设备与实验室

-在医疗影像设备、实验仪器中调节电机转速,保障设备稳定运行。

教育与科研

-作为教学工具,帮助学生理解电机控制原理及PWM技术应用。

_cuva

_cuva

VARIAN 100010077-06 DC speed regulator control board is an electronic device designed for DC motor speed control.It is widely used in many fields such as industry,new energy,transportation,etc.The following is a comprehensive analysis of its core functions and technical features:

I.Core functions and technical features

Power management

Integrated high-efficiency power management circuit can stabilize the output voltage and prevent overcurrent,overvoltage and other problems to ensure the safe operation of the motor and system.

PWM speed control

Using pulse width modulation(PWM)technology,the average voltage of the motor is dynamically adjusted by adjusting the pulse width to achieve wide-range speed regulation(such as low speed stability,high speed and high efficiency),fast response speed and high control accuracy.

Speedfeedback and closed-loop control

Equipped with encoder or Hall effect sensor interface,real-time acquisition of motor speed signal and closed-loop feedback to ensure that the actual speed is consistent with the set value.

Protection function

With multiple protection mechanisms such as overcurrent,overvoltage,overheating,etc.,it can automatically cut off the power supply or trigger an alarm to avoid equipment damage.

Communication and scalability

Supports communication protocols such as RS-485 and Ethernet,and can be connected to a host computer or PLC for remote control and data interaction;some models provide programmable interfaces,allowing users to customize parameter settings.

Adjustable parameters

Users can adjust parameters such as acceleration and deceleration time and current limit through configuration tools to adapt to different motor characteristics and application scenario requirements.

2.Application scenarios

Industrial automation

-Control conveyor belts,fans,pumps and other mechanical equipment on the production line to optimize production efficiency and accuracy.

New energy field

-Adjust motor speed in solar photovoltaic and wind power generation systems to achieve maximum power tracking(MPPT)and energy conversion efficiency optimization.

Transportation

-Applied to electric vehicles,electric bicycles and other transportation tools to accurately control motor torque and driving performance.

Household appliances and robotics

-Used in household appliances such as power tools and blenders,as well as robot joint motion control to improve operational flexibility.

Medical equipment and laboratories

-Adjust motor speed in medical imaging equipment and experimental instruments to ensure stable operation of equipment.

Education and Research

-As a teaching tool,it helps students understand the principles of motor control and the application of PWM technology.