描述

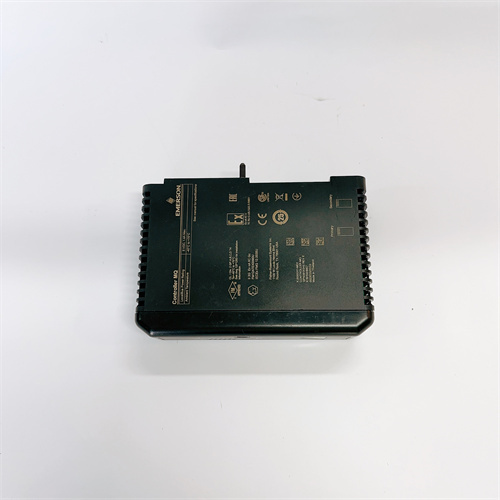

VE3008 CE3008 KJ2005X1-MQ1 12P6381X042是艾默生(Emerson)公司为工业自动化系统设计的多模块集成解决方案,涵盖控制器、伺服控制、电源和通信接口功能,适用于高精度、高可靠性场景。以下是其核心功能与技术特性概述:

1.组成与核心模块

VE3008:

作为DeltaV系统的核心控制器或电源模块,提供高性能计算与稳定供电能力。

支持高速以太网通信(100Mbps全双工)和冗余自适应地址分配,简化系统部署。

CE3008:

控制引擎模块,负责实时数据采集、处理与控制策略执行,适用于复杂工业流程(如化工、电力)。

KJ2005X1-MQ1:

DeltaV分布式控制系统模块,支持HART协议设备连接,实现智能现场设备的诊断与数据管理。

12P6381X042:

I/O接口模块,提供数字量、模拟量输入输出及通信扩展功能,兼容CAN、Profibus等协议。

2.核心功能与技术特点

高精度控制:

伺服控制器模块支持位置、速度、扭矩多模式控制,适用于机器人、机械臂等精密运动场景。

支持高速响应(100ms扫描周期)与低延迟通信,满足实时性要求。

多协议兼容性:

集成以太网、RS-485、Modbus等通信接口,可无缝对接PLC、DCS及智能设备(如三菱、西门子)。

高可靠性与防护:

工作温度范围-40°C至70°C,防护等级IP65,适应恶劣工业环境。

内置过流、过压保护及冗余电源设计,降低故障风险。

灵活扩展性:

模块化设计支持I/O通道动态分配,适用于从小型到复杂系统的扩展需求。

3.应用场景

工业自动化:

用于化工、电力、冶金等行业的过程控制,实现温度、压力、流量的闭环调节。

运动控制:

驱动伺服电机,应用于机械臂、CNC机床等高精度设备。

远程监控:

通过以太网实现设备状态远程访问与故障诊断,提升运维效率。

VE3008 CE3008 KJ2005X1-MQ1 12P6381X042 is a multi-module integrated solution designed by Emerson for industrial automation systems,covering controller,servo control,power supply and communication interface functions,suitable for high-precision and high-reliability scenarios.The following is an overview of its core functions and technical features:

1.Composition and core modules

VE3008:

As the core controller or power module of the DeltaV system,it provides high-performance computing and stable power supply capabilities.

Supports high-speed Ethernet communication(100Mbps full-duplex)and redundant adaptive address allocation to simplify system deployment.

CE3008:

Control engine module,responsible for real-time data acquisition,processing and control strategy execution,suitable for complex industrial processes(such as chemical industry and power).

KJ2005X1-MQ1:

DeltaV distributed control system module,supports HART protocol device connection,and realizes diagnosis and data management of intelligent field equipment.

12P6381X042:

I/O interface module,providing digital,analog input and output and communication expansion functions,compatible with CAN,Profibus and other protocols.

2.Core functions and technical features

High-precision control:

The servo controller module supports multi-mode control of position,speed and torque,suitable for precision motion scenarios such as robots and robotic arms.

Supports high-speed response(100ms scanning cycle)and low-latency communication to meet real-time requirements.

Multi-protocol compatibility:

Integrated communication interfaces such as Ethernet,RS-485,Modbus,etc.,can seamlessly connect PLC,DCS and intelligent devices(such as Mitsubishi,Siemens).

High reliability and protection:

Operating temperature range-40°C to 70°C,protection level IP65,adaptable to harsh industrial environments.

Built-in overcurrent,overvoltage protection and redundant power supply design to reduce the risk of failure.

Flexible scalability:

The modular design supports dynamic allocation of I/O channels,suitable for expansion needs from small to complex systems.

3.Application scenarios

Industrial automation:

Used for process control in chemical,electric power,metallurgy and other industries to achieve closed-loop regulation of temperature,pressure and flow.

Motion control:

Drive servo motors,applied to high-precision equipment such as robotic arms and CNC machine tools.

Remote monitoring:

Remote access to equipment status and fault diagnosis through Ethernet to improve operation and maintenance efficiency.