描述

一、产品定位与核心优势

1.目标应用场景

半导体制造:晶圆传输、芯片贴装、光刻机对位等超精密运动控制。

医疗设备:CT扫描仪、显微操作台、输液泵等低振动、高可靠性需求场景。

3C自动化:手机组装、屏幕检测、摄像头调焦等高速、高重复定位精度任务。

机器人关节:协作机器人(Cobot)的末端执行器定位,需低噪音、平滑运动。

实验室仪器:光谱分析仪、流式细胞仪等需要稳定速度控制的设备。

2.核心优势

高分辨率控制:支持200步/转(1.8°步距角),通过微步驱动(最高1/256细分)可实现0.007°/步的超精细定位。

低振动设计:采用自适应电流控制(ACC)和动态阻尼算法,抑制中低频共振,运动更平滑。

高速响应****:启动频率达500 Hz,可快速达到目标速度,缩短定位时间。

紧凑集成:驱动器与电机一体化设计,节省安装空间,简化布线复杂度。

高可靠性:通过IP20防护等级和过流、过压、过热保护,适应工业环境长期运行。

二、技术规格与参数

1.电机参数

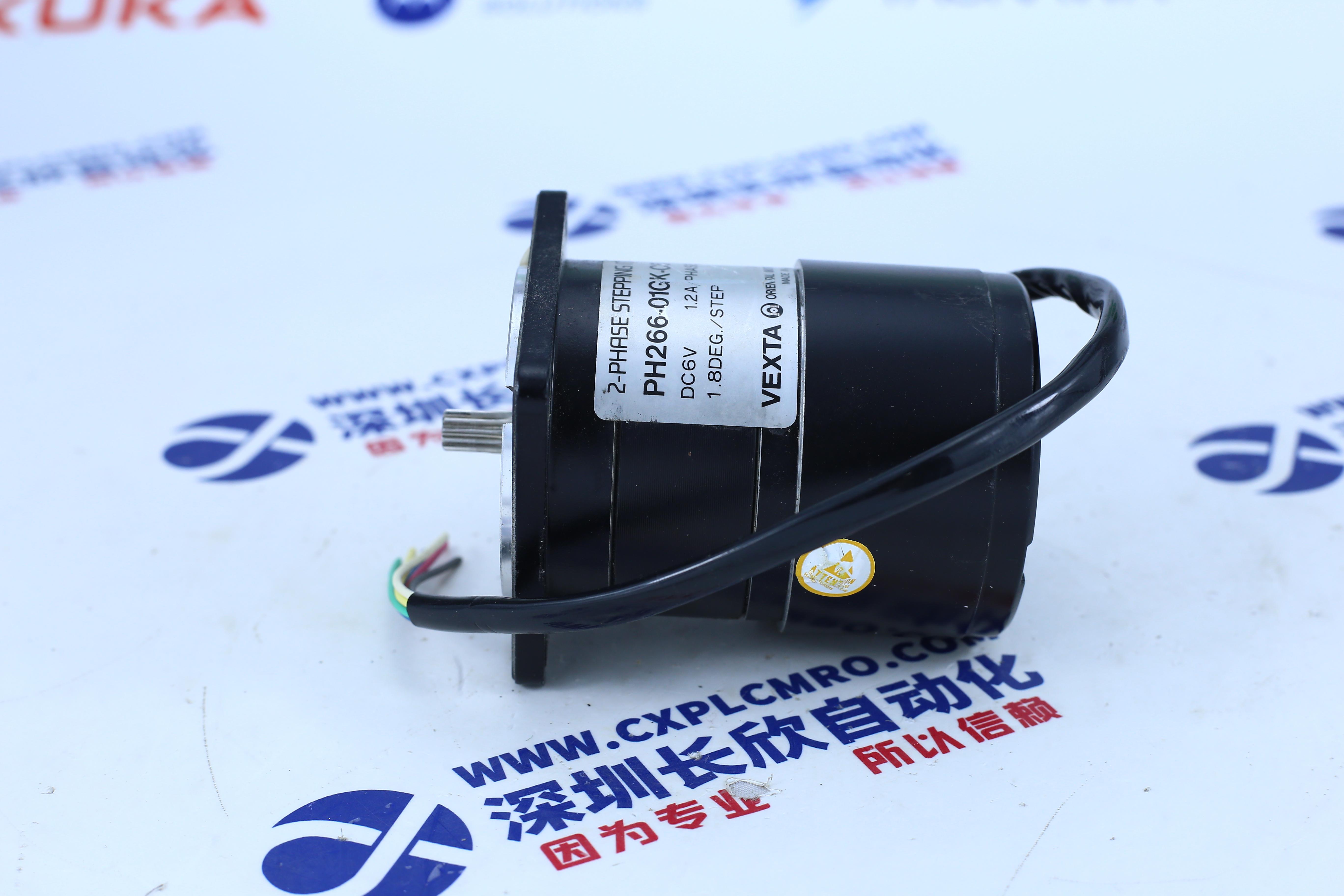

参数详情

型号后缀PH266-01GK-C501

-“01GK”:电机类型(如两相混合式步进电机)

-“C501”:驱动器配置(如细分设置、接口类型)

相数2相(标准步进电机结构,平衡扭矩与成本)

步距角1.8°(全步),通过细分可实现0.007°~1.8°可调

保持转矩0.5 N·m(5.1 kgf·cm)(典型值,适合中小负载应用)

相电流1.0 A/相(额定),支持0~1.5 A可调(通过驱动器设置)

转子惯量23 kg·cm²(低惯量设计,适合快速启停场景)

电机长度约66 mm(紧凑型,适配空间受限设备)

重量约0.8 kg(含驱动器,轻量化设计)

2.驱动器参数

参数详情

细分设置1/2~1/256细分(通过DIP开关或软件配置,默认1/16细分)

供电电压DC 24~48 V(宽电压范围,适应不同电源条件)

控制信号脉冲/方向(Pulse/Dir)或CW/CCW(正反转)模式

输入频率0~200 kHz(支持高速脉冲输入)

保护功能过流、过压、欠压、过热、短路保护(自动断电,防止损坏)

接口类型差分信号输入(RS-422)(抗干扰能力强,适合长距离传输)

通信接口可选RS-485通信(支持多轴联动控制)

环境适应性工作温度:0~50°C

存储温度:-20~70°C

湿度:<85%RH(无冷凝)

三、结构与功能特点

1.电机设计

两相混合式结构:结合永磁式(高效率)和反应式(高精度)优点,平衡扭矩与定位精度。

低惯量转子:采用钕铁硼(NdFeB)磁钢,减少加速/减速时间,提升动态响应。

精密轴承:使用双列深沟球轴承,降低摩擦与振动,延长使用寿命。

2.驱动器技术

自适应电流控制(ACC):根据负载变化动态调整相电流,减少发热与能耗。

动态阻尼算法:通过实时监测电机振动,自动调整驱动参数,抑制共振现象。

微步驱动:将单步分割为256份,实现平滑运动,降低低速爬行(Cogging)。

高速脉冲处理:支持200 kHz输入频率,确保高速定位时的指令跟随性。

1.Product positioning and core advantages

1.Target application scenarios

Semiconductor manufacturing:wafer transfer,chip mounting,photolithography machine alignment,etc.Ultra-precision motion control.

Medical equipment:CT scanners,micro-operating tables,infusion pumps,etc.Low vibration,high reliability demand scenarios.

3C automation:mobile phone assembly,screen detection,camera focusing,etc.High-speed,high repeatability positioning accuracy tasks.

Robot joints:The end effector positioning of collaborative robots(Cobot)requires low noise and smooth motion.

Laboratory instruments:Spectrometers,flow cytometers,etc.Equipment that requires stable speed control.

2.Core advantages

High-resolution control:supports 200 steps/turn(1.8°step angle),and can achieve ultra-fine positioning of 0.007°/step through micro-step drive(up to 1/256 subdivision).

Low vibration design:Adaptive current control(ACC)and dynamic damping algorithm are used to suppress medium and low frequency resonance and smoother movement.

High-speed response****:The starting frequency reaches 500 Hz,which can quickly reach the target speed and shorten the positioning time.

Compact integration:The integrated design of the driver and motor saves installation space and simplifies the wiring complexity.

High reliability:With IP20 protection level and over-current,over-voltage and over-heat protection,it can adapt to long-term operation in industrial environments.

2.Technical specifications and parameters

1.Motor parameters

Parameters Details

Model suffix PH266-01GK-C501

-“01GK”:Motor type(such as two-phase hybrid stepper motor)

-“C501”:Driver configuration(such as subdivision settings,interface type)

Number of phases 2 phases(standard stepper motor structure,balancing torque and cost)

Step angle 1.8°(full step),adjustable from 0.007°to 1.8°through subdivision

Holding torque 0.5 N·m(5.1 kgf·cm)(typical value,suitable for small and medium load applications)

Phase current 1.0 A/phase(rated),supports 0~1.5 A adjustable(set by driver)

Rotor inertia 23 kg·cm²(low inertia design,suitable for fast start and stop scenarios)

Motor length Approximately 66 mm(compact,suitable for space-constrained equipment)

Weight Approximately 0.8 kg(including driver,lightweight design)

2.Driver parameters

Parameter Details

Subdivision setting 1/2~1/256 subdivision(configured by DIP switch or software,default 1/16 subdivision)

Power supply voltage DC 24~48 V(wide voltage range,adapt to different power supply conditions)

Control signal Pulse/direction(Pulse/Dir)or CW/CCW(forward and reverse)mode

Input frequency 0~200 kHz(support high-speed pulse input)

Protection function Overcurrent,overvoltage,undervoltage,overheating,short circuit protection(automatic power off to prevent damage)

Interface type Differential signal input(RS-422)(strong anti-interference ability,suitable for long-distance transmission)

Communication interface Optional RS-485 communication(support multi-axis linkage control)

Environmental adaptability Working temperature:0~50°C

Storage temperature:-20~70°C

Humidity:<85%RH(no condensation)

III.Structural and functional features

1.Motor design

Two-phase hybrid structure:combines the advantages of permanent magnet(high efficiency)and reactive(high precision)to balance torque and positioning accuracy.

Low inertia rotor:uses neodymium iron boron(NdFeB)magnets to reduce acceleration/deceleration time and improve dynamic response.

Precision bearings:use double-row deep groove ball bearings to reduce friction and vibration and extend service life.

2.Drive technology

Adaptive current control(ACC):dynamically adjusts phase current according to load changes to reduce heat generation and energy consumption.

Dynamic damping algorithm:automatically adjusts drive parameters and suppresses resonance by real-time monitoring of motor vibration.

Microstep drive:divides a single step into 256 parts to achieve smooth movement and reduce low-speed crawling(Cogging).

High-speed pulse processing:supports 200 kHz input frequency to ensure command followability during high-speed positioning.

ABB 型号:GBU72 3BHE055094R0002 型号:3BHE055094R0002 GBU72 型号:GBU72 型号:3BHE055094R0002 型号:3BHE031197R0001 型号:3BHB030310R0001 型号:73BHE055094R0002 GBU72 型号:73BHE055094R0002 型号:GBU72 型号:ABB PCS6000 PRODUCT FAMLIYABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101