描述

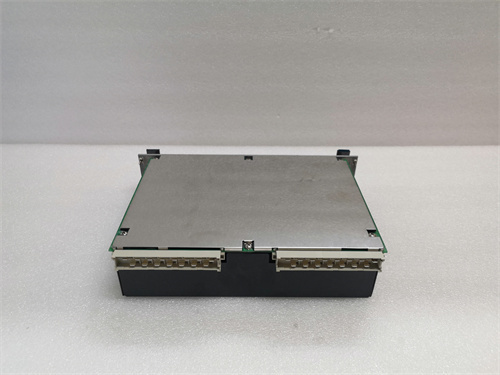

Vibro-meter 200-582-500-021数字输入模块产品详情

1.产品概述

Vibro-meter 200-582-500-021是Meggit公司(原Vibro-meter)开发的数字输入模块,专为振动监测与控制系统设计,适用于工业环境中的旋转设备(如电机、泵、风机)的实时状态监测与故障诊断。该模块支持多通道输入、数字信号处理及灵活的通信扩展,具备高可靠性和环境适应性。

2.核心功能与特性

(1)多通道输入与信号处理

多通道输入:支持连接多个振动传感器或其他数字信号源,可同时监测多个设备或信号。

数字信号处理:解析传感器输出的数字信号,提取振动特征参数(如加速度、速度、位移)。

(2)实时监测与数据分析

实时监测:实时采集振动水平、频率、幅度等数据,检测异常振动或故障。

报警功能:设置阈值触发报警,支持生成报警通知。

数据存储与历史记录:部分型号支持存储历史数据,用于后续分析和报告生成。

(3)通信与扩展性

通信接口:

工业总线:CAN(J1939协议)、RS-232/RS-422/RS-485。

网络通信:以太网(TCP/IP),支持与上位机或监控系统数据交互。

模块化设计:可扩展功能模块,适配不同监测需求。

(4)工业级可靠性

宽温范围:-40°C至+80°C,适用于极端环境。

电源输入:8-32V DC,抗干扰能力强。

输出通道:6路数字/模拟输出,支持4A负载,具备过流保护与可编程状态监测。

(5)可编程与灵活性

可编程功能:支持用户自定义配置,适配不同应用场景。

算法集成:通过C语言或SIMULINK调用专用功能库,简化代码开发。

3.技术参数

参数描述

输入通道多通道数字输入,支持振动传感器及其他数字信号源。

通信协议CAN(J1939)、Modbus、EtherNet/IP、RS-232/RS-485/RS-422。

输出通道6路(4A/通道),支持过流保护与状态监测。

工作温度-40°C~+80°C

电源输入8-32V DC

4.应用场景

工业设备监测:旋转机械(如电机、泵、风机)、发动机驱动设备的振动状态分析。

重型设备控制:采矿设备、农业机械、海洋设备的振动故障诊断。

自动化系统集成:与工业网络(如SCADA)结合,实现远程监控与数据可视化。

Vibro-meter 200-582-500-021 digital input module product details

1.Product Overview

Vibro-meter 200-582-500-021 is a digital input module developed by Meggit(formerly Vibro-meter).It is designed for vibration monitoring and control systems and is suitable for real-time status monitoring and fault diagnosis of rotating equipment(such as motors,pumps,and fans)in industrial environments.The module supports multi-channel input,digital signal processing,and flexible communication expansion,and has high reliability and environmental adaptability.

2.Core functions and features

(1)Multi-channel input and signal processing

Multi-channel input:supports connecting multiple vibration sensors or other digital signal sources,and can monitor multiple devices or signals at the same time.

Digital signal processing:analyzes the digital signal output by the sensor and extracts vibration characteristic parameters(such as acceleration,velocity,and displacement).

(2)Real-time monitoring and data analysis

Real-time monitoring:collects vibration level,frequency,amplitude and other data in real time to detect abnormal vibration or faults.

Alarm function:sets thresholds to trigger alarms and supports generating alarm notifications.

Data storage and history:Some models support storage of historical data for subsequent analysis and report generation.

(3)Communication and scalability

Communication interface:

Industrial bus:CAN(J1939 protocol),RS-232/RS-422/RS-485.

Network communication:Ethernet(TCP/IP),supports data interaction with the host computer or monitoring system.

Modular design:Expandable functional modules to adapt to different monitoring needs.

(4)Industrial-grade reliability

Wide temperature range:-40°C to+80°C,suitable for extreme environments.

Power input:8-32V DC,strong anti-interference ability.

Output channel:6 digital/analog outputs,support 4A load,with overcurrent protection and programmable status monitoring.

(5)Programmable and flexible

Programmable function:supports user-defined configuration and adapts to different application scenarios.

Algorithm integration:Call dedicated function libraries through C language or SIMULINK to simplify code development.

3.Technical Parameters

Parameter Description

Input Channel Multi-channel digital input,supports vibration sensors and other digital signal sources.

Communication Protocol CAN(J1939),Modbus,EtherNet/IP,RS-232/RS-485/RS-422.

Output Channel 6(4A/channel),supports overcurrent protection and status monitoring.

Operating Temperature-40°C~+80°C

Power Input 8-32V DC

4.Application Scenarios

Industrial Equipment Monitoring:Vibration state analysis of rotating machinery(such as motors,pumps,fans),engine-driven equipment.

Heavy Equipment Control:Vibration fault diagnosis of mining equipment,agricultural machinery,and marine equipment.

Automation System Integration:Combined with industrial networks(such as SCADA)to achieve remote monitoring and data visualization.