描述

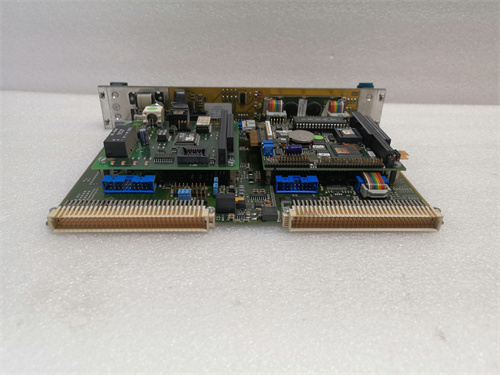

Vibro-meter 200-595-031-111 VM600 CPUM产品详情

1.产品概述

Vibro-meter 200-595-031-111 VM600 CPUM是Meggitt公司(原Vibro-meter)推出的模块化CPU卡,属于VM600系列机架控制器和通信接口卡对(CPUM/IOCN)的核心组件。它作为机械保护系统(MPS)和状态监测系统(CMS)的系统控制器及数据通信网关,支持多协议通信、实时数据处理和工业环境下的高可靠性运行。

2.核心功能与特性

(1)通信与协议支持

通信接口:支持Modbus RTU/TCP和PROFINET协议,兼容以太网(TCP/IP)及RS-232串行通信,可连接运行VM600 MPSx软件的计算机进行配置管理。

冗余扩展:支持与冗余版本(如CPUR/IOCR)配合使用,增强系统稳定性。

(2)实时监测与控制

数据处理:内置AMD Geode™LX800处理器(500MHz)和256MB DRAM,实时处理振动、温度、压力等传感器数据。

报警管理:通过前面板显示屏显示保护卡的监控输出和报警限值,并支持通用报警复位(AR)功能。

(3)事件日志与配置

日志记录:存储系统事件和测量事件日志(最多10,000条),可通过软件查看分析。

配置管理:通过以太网或RS-232实现“一次性”配置,简化系统部署。

(4)工业级可靠性

环境适应性:工作温度范围-40°C至+70°C,防护等级IP65,适用于恶劣工业环境。

电源支持:兼容24V DC电源模块(如200-595-031-111型号),提供稳定供电。

3.技术规格

参数描述

处理器AMD Geode™LX800(500MHz)

内存256MB DRAM

通信协议Modbus RTU/TCP、PROFINET、以太网(TCP/IP)、RS-232

接口以太网(RJ45)、RS-232、前面板显示屏

电源24V DC(需外接电源模块)

工作温度-40°C~+70°C

防护等级IP65

尺寸19英寸机架安装

重量约2-4kg(具体取决于配套模块)

4.应用场景

工业设备监测:发电厂汽轮机、石油天然气泵、造纸机等旋转机械的振动监测与故障诊断。

自动化系统集成:与PLC、DCS系统(如西门子、ABB)协同工作,实现工业网络数据共享。

状态监控:实时分析轴承状态、润滑系统性能,预防设备停机。

Vibro-meter 200-595-031-111 VM600 CPUM Product Details

1.Product Overview

The Vibro-meter 200-595-031-111 VM600 CPUM is a modular CPU card launched by Meggitt(formerly Vibro-meter).It is a core component of the VM600 series rack controller and communication interface card pair(CPUM/IOCN).As a system controller and data communication gateway for the machinery protection system(MPS)and condition monitoring system(CMS),it supports multi-protocol communication,real-time data processing and high-reliability operation in industrial environments.

2.Core functions and features

(1)Communication and protocol support

Communication interface:supports Modbus RTU/TCP and PROFINET protocols,is compatible with Ethernet(TCP/IP)and RS-232 serial communication,and can be connected to a computer running VM600 MPSx software for configuration management.

Redundancy expansion:supports use with redundant versions(such as CPUR/IOCR)to enhance system stability.

(2)Real-time monitoring and control

Data processing:Built-in AMD Geode™LX800 processor(500MHz)and 256MB DRAM,real-time processing of vibration,temperature,pressure and other sensor data.

Alarm management:Displays the monitoring output and alarm limit of the protection card through the front panel display,and supports the general alarm reset(AR)function.

(3)Event log and configuration

Log recording:Stores system event and measurement event logs(up to 10,000),which can be viewed and analyzed through software.

Configuration management:”One-time”configuration is achieved through Ethernet or RS-232 to simplify system deployment.

(4)Industrial-grade reliability

Environmental adaptability:Operating temperature range-40°C to+70°C,protection level IP65,suitable for harsh industrial environments.

Power support:Compatible with 24V DC power supply module(such as model 200-595-031-111),providing stable power supply.

3.Technical Specifications

Parameter Description

Processor AMD Geode™LX800(500MHz)

Memory 256MB DRAM

Communication Protocol Modbus RTU/TCP,PROFINET,Ethernet(TCP/IP),RS-232

Interface Ethernet(RJ45),RS-232,front panel display

Power Supply 24V DC(external power module required)

Operating Temperature-40°C~+70°C

Protection Level IP65

Dimensions 19-inch rack mount

Weight Approximately 2-4kg(depending on the supporting module)

4.Application Scenarios

Industrial Equipment Monitoring:Vibration monitoring and fault diagnosis of rotating machinery such as power plant turbines,oil and gas pumps,and paper machines.

Automation System Integration:Work with PLC and DCS systems(such as Siemens,ABB)to achieve industrial network data sharing.

Condition Monitoring:Real-time analysis of bearing status and lubrication system performance to prevent equipment downtime.