描述

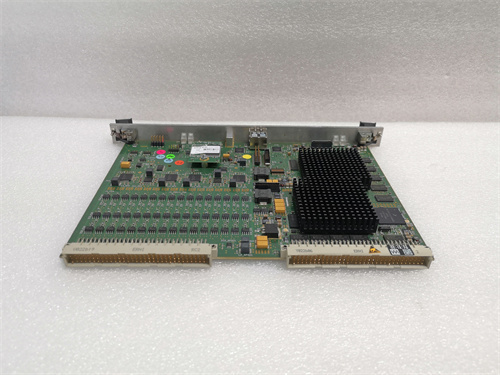

Vibro-meter 600-003 620-001-001-116 VM600 XMV16振动状态监测模块产品详情

1.产品概述

VM600 XMV16是Meggit公司(原Vibro-meter)推出的高性能振动状态监测模块,专为旋转机械(如汽轮机、泵、风机)的振动监测与故障诊断设计。它属于VM600系列机架式机械监控系统的核心组件,支持高密度通道扩展和复杂信号处理,适用于工业环境中的实时监测与保护需求。

2.核心功能与特性

(1)多通道输入与信号处理

通道配置:

16个动态通道:支持加速度、速度、位移等振动信号输入,可独立编程配置。

4个转速计通道:用于测量转速(1-100,000 RPM)及相位参考,支持电压/电流输入。

信号处理:

24位高分辨率数据采集,信噪比高,支持FFT频谱分析(最高每500ms 6400行)。

数字滤波与算法:包括阶次跟踪、峰值检测、时域分析等,提取关键振动特征参数(如幅值、频率、相位)。

(2)实时监测与报警

实时监控:持续监测设备振动状态,检测异常波动或故障(如轴承磨损、不平衡)。

报警功能:支持自适应报警阈值设置,可触发本地继电器或通过总线发送报警信号。

(3)通信与集成

通信接口:

以太网(TCP/IP):支持Modbus RTU/TCP、PROFINET协议,与上位机或SCADA系统对接。

工业总线:通过OC总线与机架其他模块(如继电器卡、输入/输出卡)通信。

软件支持:兼容VibroSight分析软件,实现数据可视化与深度诊断。

(4)模块化设计

卡对配置:需与XIO16T输入/输出模块组合使用,形成“卡对”结构,支持扩展I/O通道与复杂监控任务。

机架兼容性:适配VM600系列机架(如ABE040、ABE056),支持热插拔维护。

3.技术规格

参数描述

通道数量16个动态通道+4个转速计通道

数据采集24位分辨率,信噪比高,FFT分辨率6400行/500ms

转速测量范围1-100,000 RPM(0.017 Hz至1.667 kHz)

输入信号类型加速度计、接近探头、速度传感器(电压/电流输入)

通信协议Modbus RTU/TCP、PROFINET、以太网(TCP/IP)、OC总线

电源要求需搭配RPS6U电源模块(24V DC),支持宽电压输入(18-58V DC)

工作温度-40°C至+70°C

防护等级未明确标注(但符合工业环境抗干扰设计)

4.应用场景

大型工业设备:发电厂汽轮机、石油天然气泵、化工机械等旋转设备的振动监测与保护。

状态监控系统:结合VibroSight软件实现预测性维护,减少非计划停机。

Vibro-meter 600-003 620-001-001-116 VM600 XMV16 Vibration Condition Monitoring Module Product Details

1.Product Overview

VM600 XMV16 is a high-performance vibration condition monitoring module launched by Meggit(formerly Vibro-meter),designed for vibration monitoring and fault diagnosis of rotating machinery(such as turbines,pumps,and fans).It is a core component of the VM600 series rack-mounted machinery monitoring system,supporting high-density channel expansion and complex signal processing,and is suitable for real-time monitoring and protection needs in industrial environments.

2.Core functions and features

(1)Multi-channel input and signal processing

Channel configuration:

16 dynamic channels:support acceleration,velocity,displacement and other vibration signal input,which can be independently programmed and configured.

4 tachometer channels:used to measure speed(1-100,000 RPM)and phase reference,supporting voltage/current input.

Signal processing:

24-bit high-resolution data acquisition,high signal-to-noise ratio,support FFT spectrum analysis(up to 6400 lines per 500ms).

Digital filtering and algorithms:including order tracking,peak detection,time domain analysis,etc.,to extract key vibration characteristic parameters(such as amplitude,frequency,phase).

(2)Real-time monitoring and alarm

Real-time monitoring:Continuously monitor the vibration status of the equipment and detect abnormal fluctuations or faults(such as bearing wear and imbalance).

Alarm function:Supports adaptive alarm threshold setting,which can trigger local relays or send alarm signals through the bus.

(3)Communication and integration

Communication interface:

Ethernet(TCP/IP):Supports Modbus RTU/TCP,PROFINET protocols,and connects to the host computer or SCADA system.

Industrial bus:Communicates with other modules of the rack(such as relay cards,input/output cards)through the OC bus.

Software support:Compatible with VibroSight analysis software to achieve data visualization and in-depth diagnosis.

(4)Modular design

Card pair configuration:It needs to be used in combination with the XIO16T input/output module to form a”card pair”structure,which supports the expansion of I/O channels and complex monitoring tasks.

Rack compatibility:It is compatible with the VM600 series racks(such as ABE040,ABE056)and supports hot-swap maintenance.

3.Technical Specifications

Parameter Description

Number of channels 16 dynamic channels+4 tachometer channels

Data acquisition 24-bit resolution,high signal-to-noise ratio,FFT resolution 6400 lines/500ms

Speedmeasurement range 1-100,000 RPM(0.017 Hz to 1.667 kHz)

Input signal type Accelerometer,proximity probe,speed sensor(voltage/current input)

Communication protocol Modbus RTU/TCP,PROFINET,Ethernet(TCP/IP),OC bus

Power requirements Requires RPS6U power module(24V DC),supports wide voltage input(18-58V DC)

Operating temperature-40°C to+70°C

Protection level Not clearly marked(but meets the anti-interference design of industrial environment)

4.Application scenarios

Large industrial equipment:vibration monitoring and protection of rotating equipment such as power plant turbines,oil and gas pumps,and chemical machinery.

Condition Monitoring System:Combined with VibroSight software,it enables predictive maintenance and reduces unplanned downtime.