描述

一、产品定位与核心功能

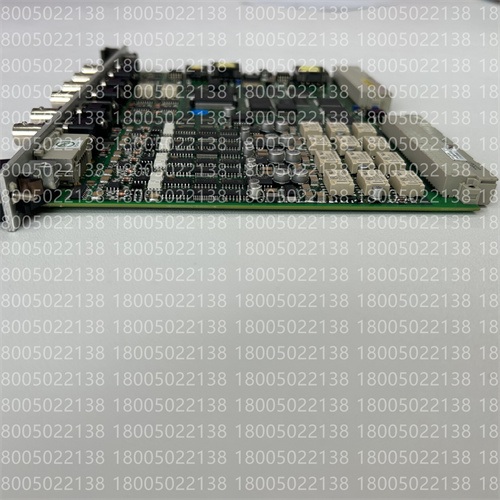

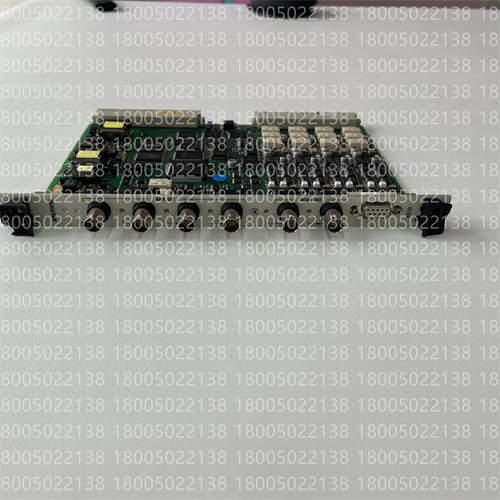

模块类型

-机械保护卡:用于实时监测旋转机械(如涡轮机、压缩机、发电机)的振动、轴位移等参数,并在异常时触发报警或停机保护。

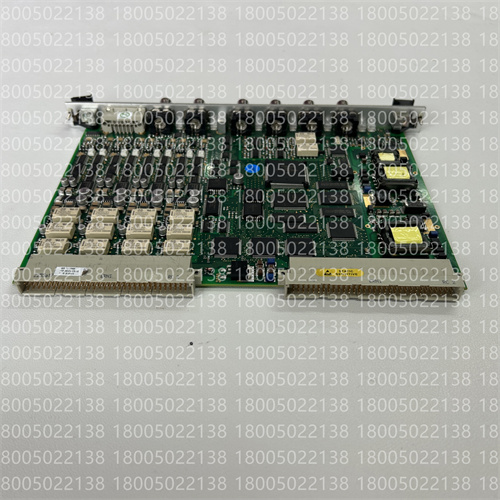

核心功能

-多通道信号处理:支持4个动态信号输入(加速度、速度、位移)和2个转速输入,所有通道独立可编程;

-高级数字处理:集成数字滤波、积分/微分、阶次跟踪(幅值与相位)、真峰值检测等功能;

-安全保护机制:内置SIL 2认证(安全完整性等级),支持两级报警(预报警/危险报警)及继电器输出,确保设备安全。

二、关键技术参数

|项目|参数/功能|

|输入类型|动态信号:加速度计、速度传感器、涡流探头;转速信号:接近传感器、磁脉冲传感器|

|通道数量|4动态通道+2转速通道|

|测量范围|电压:±10V(交流)/0–20V(直流);电流:0–25mA(直流)|

|精度与响应|高分辨率测量,响应时间毫秒级|

|通信接口|Modbus、4–20mA模拟输出、继电器触点|

|环境适应性|工作温度:-20°C至+65°C;防护等级:IP20|

三、典型应用场景

能源与电力

-汽轮机、发电机轴振动监测与不平衡检测;

-风力发电机轴承磨损预警。

化工与制造

-压缩机壳体膨胀监测、泵类设备预防性维护;

-高速离心机动态压力分析。

航空航天

-飞机发动机转子位移实时监控。

1.Product positioning and core functions

Module Type

-Mechanical protection card:used to monitor the vibration,shaft displacement and other parameters of rotating machinery(such as turbines,compressors,generators)in real time,and trigger alarm or shutdown protection in case of abnormalities.

Core functions

-Multi-channel signal processing:supports 4 dynamic signal inputs(acceleration,velocity,displacement)and 2 speed inputs,all channels are independently programmable;

-Advanced digital processing:Integrated digital filtering,integral/differential,order tracking(amplitude and phase),true peak detection and other functions;

-Safety protection mechanism:built-in SIL 2 certification(safety integrity level),supports two-level alarm(pre-alarm/hazardous alarm)and relay output to ensure the safety of the equipment.

2.Key technical parameters

|Project|Parameters/Functions|

|Input type|Dynamic signals:accelerometer,speed sensor,eddy current probe;speed signals:proximity sensor,magnetic pulse sensor|

|Number of channels|4 dynamic channels+2 speed channels|

|Measuring range|Voltage:±10V(AC)/0–20V(DC);Current:0–25mA(DC)|

|Accuracy and Response|High Resolution Measurement,Response Time Milliseconds|

|Communication interface|Modbus,4–20mA analog output,relay contacts|

|Environmental adaptability|Operating temperature:-20°C to+65°C;Protection level:IP20|

3.Typical application scenarios

Energy and Electricity

-Monitoring and imbalance detection of the shaft vibration of the turbine and generator;

-Wind generator bearing wear warning.

Chemical and Manufacturing

-Compressor housing expansion monitoring and preventive maintenance of pump equipment;

-Dynamic pressure analysis of high-speed centrifuge.

Aerospace

-Real-time monitoring of rotor displacement of aircraft engines.