描述

一、核心功能与定位

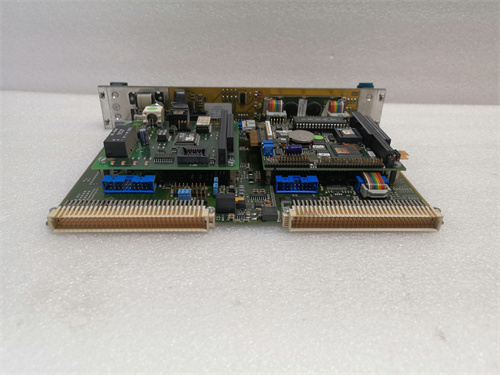

类型:工业级机械保护与状态监测模块,属于VM600系列的核心组件,专为旋转机械(如涡轮机、压缩机、泵等)的振动、位移、转速等参数监测与保护设计。

核心功能:

振动监测:实时采集加速度、速度、位移信号,支持相对振动、绝对振动、偏心率等参数分析。

位移监测:监测轴向位移、推力位置、膨胀量等关键参数。

转速与键相信号处理:支持多通道转速输入及键相跟踪,用于相位分析与故障诊断。

多级报警与保护:可编程报警阈值(警报/危险级),支持延迟、迟滞和锁存功能,触发继电器动作或紧急停机。

通信与集成:通过Modbus RTU/TCP、以太网等协议与上位机、DCS/PLC系统通信,支持数据共享与远程监控。

二、技术参数

输入特性

通道数量:4个动态信号通道+2个转速/键相通道(典型配置)。

输入类型:支持加速度、速度、位移传感器信号,兼容接近探头、磁脉冲传感器等。

输入范围:动态信号直流范围0-±20V,交流范围±10V;转速信号支持TTL、磁电式传感器等。

处理能力

数字信号处理:内置DSP技术,支持滤波(宽/窄带)、积分/微分、RMS/峰值计算及相位跟踪。

采样率:最高256次/秒,确保实时性与高精度。

输出与通信

模拟输出:提供0-10V或4-20mA缓冲信号,用于外部系统集成。

数字输出:4个本地继电器,支持报警信号驱动;通过Raw总线或OC总线扩展至RLC16/IRC4继电器卡。

通信接口:支持Modbus RTU/TCP、以太网、RS-232/485,兼容PROFINET等工业协议。

环境适应性

工作温度:-25°C至+70°C(部分版本支持更宽温域)。

防护等级:IP20(机架安装环境)。

三、核心应用场景

发电领域

涡轮机、发电机的振动与轴位移监测,预防轴承故障或转子失衡。

石油与化工

压缩机、离心机的实时状态监控,确保生产连续性。

机械制造

高速机床、精密设备的振动分析与保护。

轨道交通

列车牵引电机、转向架的动态监测。

1.Core functions and positioning

Type:Industrial-grade mechanical protection and condition monitoring module,which belongs to the core component of the VM600 series,is designed for monitoring and protection parameters such as vibration,displacement,speed,etc.of rotating machinery(such as turbines,compressors,pumps,etc.).

Core functions:

Vibration monitoring:collects acceleration,velocity,and displacement signals in real time,and supports parameter analysis such as relative vibration,absolute vibration,and eccentricity.

Displacement monitoring:Monitor key parameters such as axial displacement,thrust position,expansion volume,etc.

Speedand key phase signal processing:supports multi-channel speed input and key phase tracking,for phase analysis and fault diagnosis.

Multi-level alarm and protection:programmable alarm threshold(alarm/hazard level),supports delay,hysteresis and latch functions,triggering relay action or emergency shutdown.

Communication and integration:Communication with the host computer and DCS/PLC system through Modbus RTU/TCP,Ethernet and other protocols,supporting data sharing and remote monitoring.

2.Technical parameters

Input Features

Number of channels:4 dynamic signal channels+2 speed/key phase channels(typical configuration).

Input type:Supports acceleration,velocity,displacement sensor signals,compatible with proximity probes,magnetic pulse sensors,etc.

Input range:Dynamic signal DC range 0-±20V,AC range±10V;speed signal supports TTL,magnetoelectric sensor,etc.

Processing capability

Digital signal processing:built-in DSP technology,supports filtering(wide/narrow band),integral/differential,RMS/peak calculation and phase tracking.

Sampling rate:up to 256 times/sec,ensuring real-time and high precision.

Output and communication

Analog output:Provides 0-10V or 4-20mA buffered signals for external system integration.

Digital output:4 local relays,support alarm signal driving;extend to RLC16/IRC4 relay card through Raw bus or OC bus.

Communication interface:Supports Modbus RTU/TCP,Ethernet,RS-232/485,and is compatible with industrial protocols such as PROFINET.

Environmental adaptability

Operating temperature:-25°C to+70°C(some versions support wider temperature ranges).

Protection level:IP20(rack mounting environment).

3.Core application scenarios

Power generation field

Monitor vibration and shaft displacement of turbines and generators to prevent bearing failure or rotor imbalance.

Petroleum and Chemical Industry

Real-time status monitoring of compressors and centrifuges ensures production continuity.

Machinery manufacturing

Vibration analysis and protection of high-speed machine tools and precision equipment.

Rail Transportation

Dynamic monitoring of train traction motors and bogies.