描述

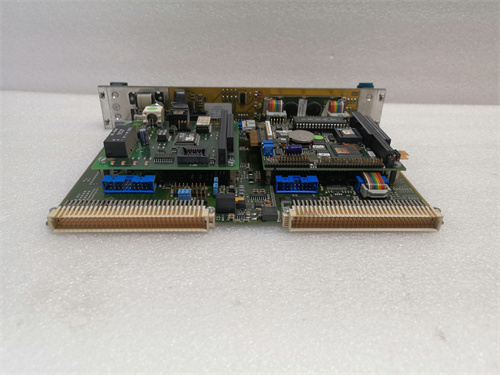

Vibro-Meter VM600 RPS6U是一款专为工业振动监测和保护系统设计的核心电源及控制模块,结合了高可靠性、多通道处理与灵活通信能力,适用于复杂工业环境。以下是其产品简介的综合解析:

一、产品概述

VM600 RPS6U是VM600系列机架式系统的电源模块,为整个系统提供稳定且冗余的直流供电(18-32Vdc,最大25A),支持电网电压波动下的连续运行。同时,该模块具备数据采集、通信与控制功能,是旋转设备振动监测、运动控制和故障诊断的核心组件。

二、核心功能

电源供应与冗余设计

提供18-32Vdc输入电压范围,支持25A最大电流输出,可为VM600系列处理卡(如MPC4机械保护卡、IOC4T输入/输出卡)供电。

支持双电源冗余配置,提升系统可靠性。

振动监测与数据处理

多通道支持:单模块可处理多达32个振动通道,覆盖加速度、速度、位移等参数,适用于涡轮机、泵、压缩机等复杂设备的全面监控。

信号分析:内置数字滤波、频域分析、趋势预测等功能,支持真峰值、RMS等数据整流方式,精准识别异常振动模式。

通信与集成能力

协议兼容性:支持Modbus、Profibus、Ethernet/IP等工业协议,可无缝对接PLC、SCADA系统或云端平台。

接口扩展:提供CAN端口(J1939协议)、RS-232/422/485串行通信端口,支持远程数据传输与报警触发。

安全与防护特性

过流保护:六个独立输出通道(4A/通道)均配备自动过流安全机制,防止设备损坏。

环境适应性:工作温度范围-40℃至70℃,防护等级IP65,符合工业级振动、冲击与跌落测试标准(如IEC 60068)。

三、技术参数

参数类型规格说明

电源输入18-32Vdc,25A max

通信接口CAN、RS-232/422/485、以太网

工作温度-40℃to 70℃

防护等级IP65(部分型号)

数据存储2GB(支持振动趋势与报警记录)

四、应用场景

能源电力:燃气轮机、发电机振动保护,防止转子失衡或轴承故障。

石油化工:压缩机、泵类设备的实时监控,减少非计划停机。

通用制造:造纸机、风机等设备的健康状态评估与预测性维护。

恶劣环境:矿山、海洋平台等高振动、高温场景的设备防护。

Vibro-Meter VM600 RPS6U is a core power supply and control module designed for industrial vibration monitoring and protection systems.It combines high reliability,multi-channel processing and flexible communication capabilities,and is suitable for complex industrial environments.The following is a comprehensive analysis of its product profile:

I.Product Overview

VM600 RPS6U is the power module for the VM600 series rack-mount system,providing stable and redundant DC power supply(18-32Vdc,maximum 25A)for the entire system,and supports continuous operation under grid voltage fluctuations.At the same time,the module has data acquisition,communication and control functions,and is a core component for vibration monitoring,motion control and fault diagnosis of rotating equipment.

II.Core Functions

Power Supply and Redundancy Design

Provides an 18-32Vdc input voltage range,supports a maximum current output of 25A,and can power VM600 series processing cards(such as MPC4 mechanical protection card,IOC4T input/output card).

Supports dual power supply redundant configuration to improve system reliability.

Vibration monitoring and data processing

Multi-channel support:A single module can process up to 32 vibration channels,covering acceleration,velocity,displacement and other parameters,suitable for comprehensive monitoring of complex equipment such as turbines,pumps,compressors,etc.

Signal analysis:Built-in digital filtering,frequency domain analysis,trend prediction and other functions,support true peak,RMS and other data rectification methods,accurately identify abnormal vibration modes.

Communication and integration capabilities

Protocol compatibility:Supports industrial protocols such as Modbus,Profibus,Ethernet/IP,and can be seamlessly connected to PLC,SCADA system or cloud platform.

Interface expansion:Provides CAN port(J1939 protocol),RS-232/422/485 serial communication port,supports remote data transmission and alarm triggering.

Safety and protection features

Overcurrent protection:Six independent output channels(4A/channel)are equipped with automatic overcurrent safety mechanism to prevent equipment damage.

Environmental adaptability:The operating temperature range is-40℃to 70℃,the protection level is IP65,and it meets industrial-grade vibration,shock and drop test standards(such as IEC 60068).

III.Technical parameters

Parameter type Specifications

Power input 18-32Vdc,25A max

Communication interface CAN,RS-232/422/485,Ethernet

Operating temperature-40℃to 70℃

Protection level IP65(some models)

Data storage 2GB(supports vibration trend and alarm records)

IV.Application scenarios

Energy and power:Vibration protection of gas turbines and generators to prevent rotor imbalance or bearing failure.

Petrochemical:Real-time monitoring of compressors and pumps to reduce unplanned downtime.

General manufacturing:Health status assessment and predictive maintenance of equipment such as paper machines and fans.

Harsh environment:Equipment protection in high-vibration and high-temperature scenarios such as mines and offshore platforms.