描述

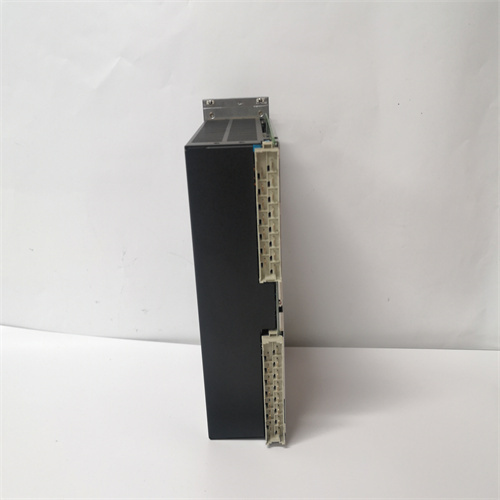

VIBRO-METER VM600 CMC16 200-530-025-014 200-530-111-013振动监测模块产品详情

1.产品概述

VM600 CMC16是Vibro-Meter(现属Meggitt公司)推出的工业级振动状态监测模块,专为旋转机械(如涡轮机、发电机、泵、压缩机)的振动监测与故障诊断设计。它属于VM600系列状态监测系统(CMS)的核心组件,支持高精度数据采集、分析及远程传输,适用于工业自动化、能源、化工等领域的设备状态监测与保护。

2.核心功能与特性

(1)多通道输入与信号处理

通道配置:

16个动态通道:支持振动(加速度、速度、位移)、相位基准、动态压力、气隙转子等信号输入,可独立编程配置。

4个转速计通道:用于测量转速(1-100,000 RPM)及相位参考,支持电压/电流输入。

信号处理:

24位高分辨率数据采集,信噪比高,支持FFT频谱分析(最高每6400ms 500行)。

同步/异步采样:支持固定频率或顺序跟踪采样模式,确保数据采集的实时性与准确性。

(2)高精度与稳定性

测量范围:200 Hz至530 Hz(振动频率)。

分辨率:0.025 mm/s(速度模式)。

精度:读数的1%,满足工业级高精度要求。

采样率:高达200 kHz(动态通道)或1024 Hz(振动监测模式)。

(3)通信与集成

通信接口:

以太网:支持Modbus RTU/TCP或PROFINET协议,与上位机或SCADA系统对接。

串行接口:RS485串行链路,兼容传统工业总线。

软件支持:

与VM600 CMS软件或VibroSight分析软件配合,实现数据可视化与深度诊断。

(4)环境适应性

工作温度:-40°C至+70°C(宽温型)。

防护等级:IP30,适用于工业环境。

存储容量:2 GB,支持长期数据存储与回溯分析。

VIBRO-METER VM600 CMC16 200-530-025-014 200-530-111-013 Vibration Monitoring Module Product Details

1.Product Overview

VM600 CMC16 is an industrial-grade vibration condition monitoring module launched by Vibro-Meter(now Meggitt),designed for vibration monitoring and fault diagnosis of rotating machinery(such as turbines,generators,pumps,compressors).It is a core component of the VM600 series condition monitoring system(CMS),supports high-precision data acquisition,analysis and remote transmission,and is suitable for equipment condition monitoring and protection in industrial automation,energy,chemical industry and other fields.

2.Core functions and features

(1)Multi-channel input and signal processing

Channel configuration:

16 dynamic channels:support vibration(acceleration,velocity,displacement),phase reference,dynamic pressure,air gap rotor and other signal inputs,which can be independently programmed and configured.

4 tachometer channels:used to measure speed(1-100,000 RPM)and phase reference,supporting voltage/current input.

Signal processing:

24-bit high-resolution data acquisition,high signal-to-noise ratio,supporting FFT spectrum analysis(up to 500 lines per 6400ms).

Synchronous/asynchronous sampling:supports fixed frequency or sequential tracking sampling mode to ensure real-time and accuracy of data acquisition.

(2)High precision and stability

Measurement range:200 Hz to 530 Hz(vibration frequency).

Resolution:0.025 mm/s(speed mode).

Accuracy:1%of reading,meeting industrial-grade high-precision requirements.

Sampling rate:up to 200 kHz(dynamic channel)or 1024 Hz(vibration monitoring mode).

(3)Communication and integration

Communication interface:

Ethernet:supports Modbus RTU/TCP or PROFINET protocol,and connects to the host computer or SCADA system.

Serial interface:RS485 serial link,compatible with traditional industrial buses.

Software support:

Works with VM600 CMS software or VibroSight analysis software to achieve data visualization and in-depth diagnosis.

(4)Environmental adaptability

Working temperature:-40°C to+70°C(wide temperature type).

Protection level:IP30,suitable for industrial environments.

Storage capacity:2 GB,supports long-term data storage and retrospective analysis.