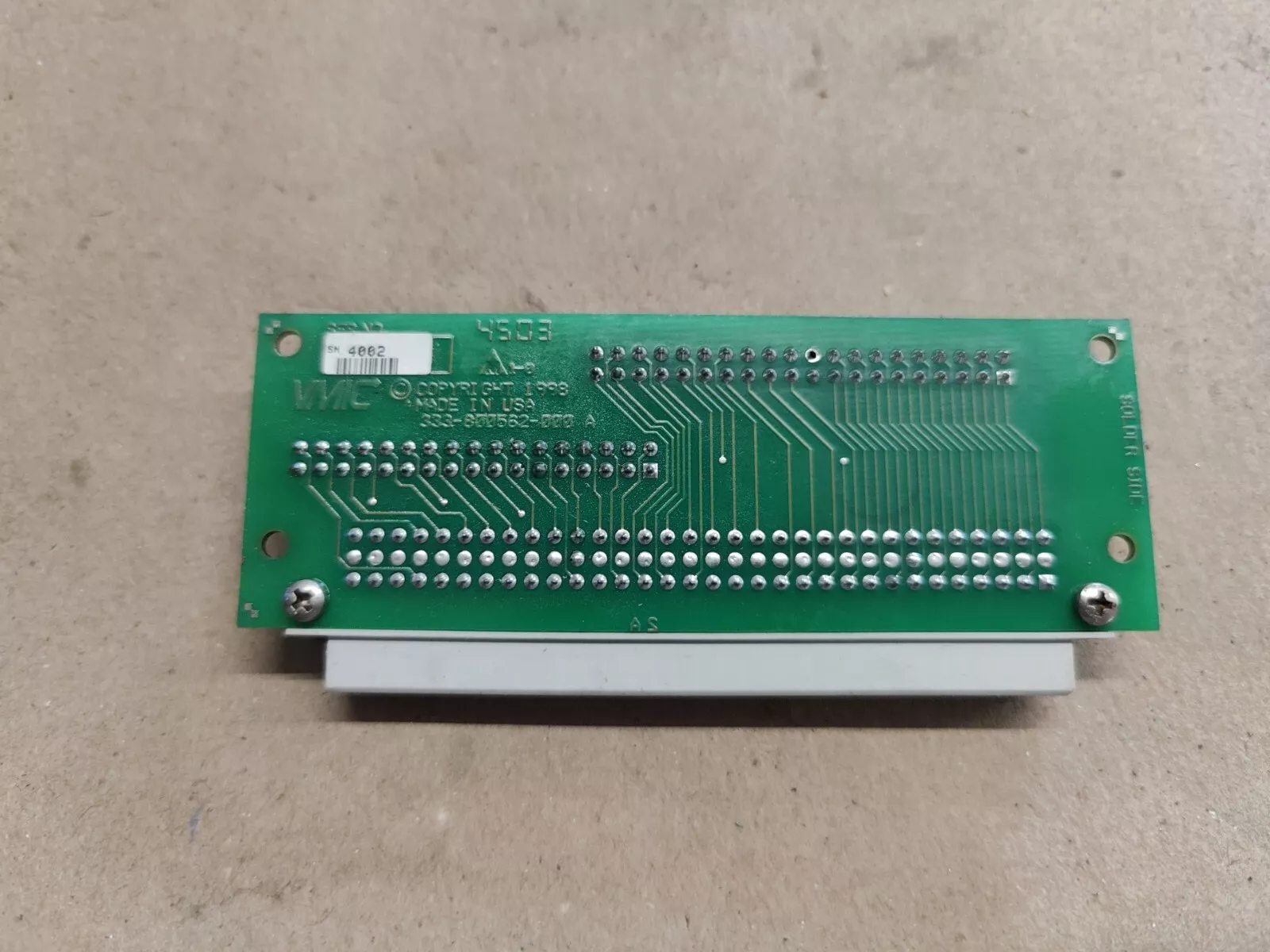

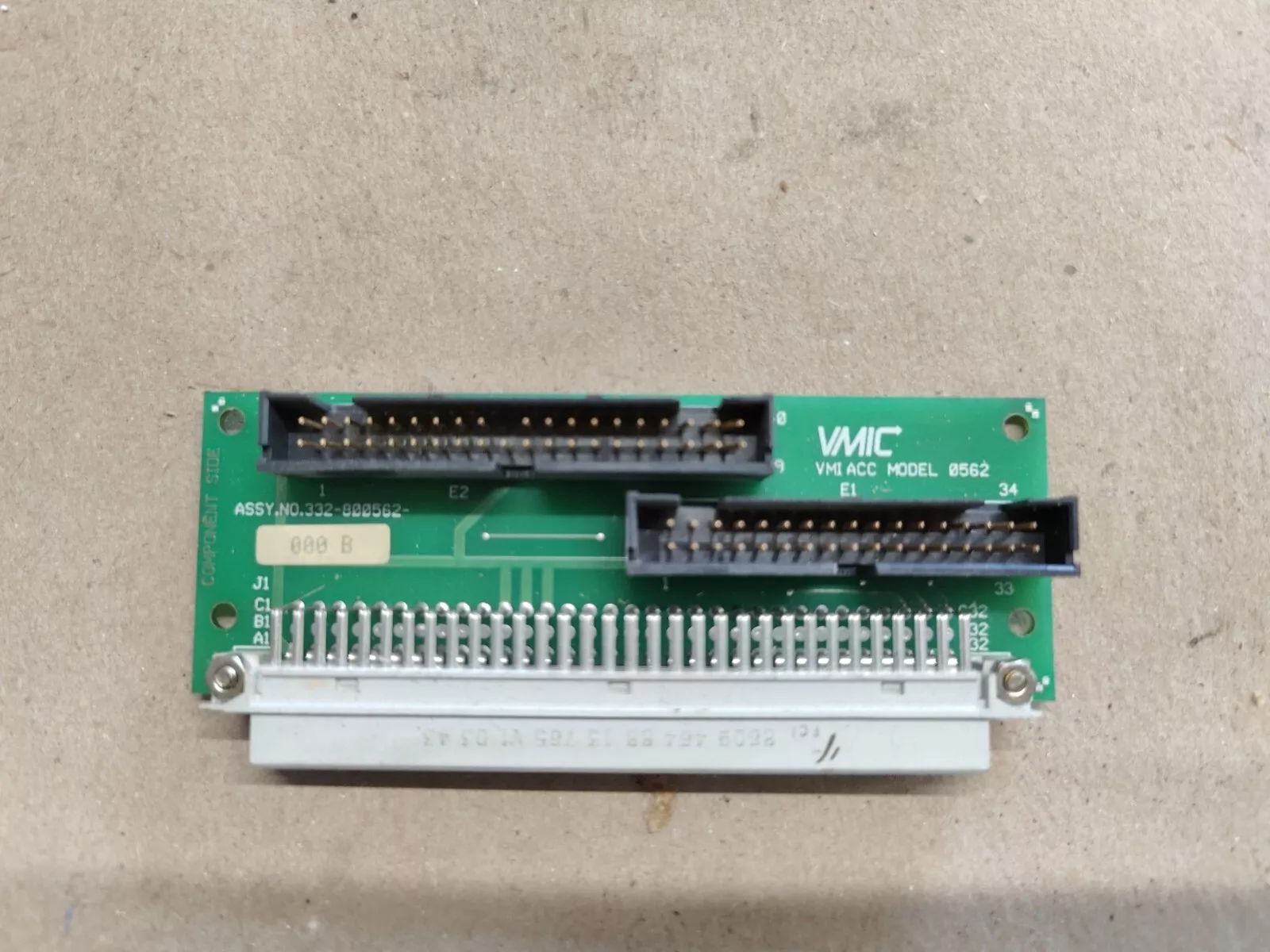

描述

VMIACC_0562产品详情

产品概述

VMIACC_0562是一款由VMI(Vibration Monitoring International)或其合作厂商推出的高精度三轴加速度传感器模块,专为工业振动监测、结构健康分析、旋转机械故障诊断等应用设计。该模块集成三轴(X/Y/Z)MEMS(微机电系统)加速度计,支持宽频带振动信号采集,并可通过数字接口(如I2C、SPI)或模拟输出与数据采集系统(DAQ)、PLC或嵌入式控制器连接。其紧凑设计、高灵敏度和抗干扰能力使其适用于恶劣工业环境。

核心功能

三轴同步测量

集成X、Y、Z三轴加速度计,可同时测量三个方向的振动信号,全面分析设备振动特征(如径向、轴向振动)。

轴间交叉干扰低(典型值<1%),确保测量独立性。

宽频带响应

频率范围:0.5 Hz至5 kHz(典型值),覆盖低频机械振动(如不平衡)到高频故障特征(如轴承缺陷)。

支持恒定电流(IEPE)或电压输出(部分型号),兼容传统振动分析仪。

高精度与高灵敏度

灵敏度:100 mV/g(典型值, 1g加速度),可检测微小振动变化。

非线性度:<0.1%FS(满量程),确保长期测量稳定性。

分辨率:可达0.001g(取决于采样率与噪声水平),满足精密诊断需求。

抗干扰设计

防护等级:IP67(防尘防水),适应潮湿、多尘环境。

温度补偿:内置温度传感器,自动修正温度漂移(-40°C至+125°C工作范围)。

电磁兼容性(EMC):符合IEC 61000标准,抗工业现场电磁干扰。

灵活的接口与供电

数字接口:支持I2C、SPI(部分型号),便于与嵌入式系统集成。

模拟输出:0-5 V或4-20 mA(可选),直接连接PLC或DAQ设备。

供电:5-24 V DC宽电压输入,低功耗设计(典型值<10 mA)。

技术规格

参数规格

测量轴三轴(X/Y/Z),正交安装

频率范围0.5 Hz至5 kHz(±3 dB)

灵敏度100 mV/g(典型值,可定制)

量程±2g/±5g/±10g(软件可配置)

非线性度<0.1%FS

分辨率0.001g(典型值)

输出接口数字:I2C/SPI;模拟:0-5 V/4-20 mA(可选)

供电5-24 V DC

工作温度-40°C至+125°C(工业级)

防护等级IP67

尺寸紧凑型设计(如30 mm×30 mm×15 mm,具体依型号)

重量<50 g(含电缆)

校准工厂校准,提供校准证书(部分型号支持现场自校准)

应用场景

旋转机械监测

风机、泵、压缩机等设备的振动分析,检测不平衡、不对中、轴承故障等。

结构健康监测

桥梁、建筑、风力发电机叶片的振动模态分析,评估结构完整性。

轨道交通

列车轴箱、齿轮箱振动监测,预防脱轨或传动系统故障。

能源行业

汽轮机、发电机振动监测,优化运维周期,减少非计划停机。

汽车测试

发动机、传动系统振动测试,验证NVH(噪声、振动与声振粗糙度)性能。

VMIACC_0562 Product Details

Product Overview

VMIACC_0562 is a high-precision three-axis acceleration sensor module launched by VMI(Vibration Monitoring International)or its partners,designed for industrial vibration monitoring,structural health analysis,rotating machinery fault diagnosis and other applications.The module integrates a three-axis(X/Y/Z)MEMS(micro-electromechanical system)accelerometer,supports wide-band vibration signal acquisition,and can be connected to a data acquisition system(DAQ),PLC or embedded controller through a digital interface(such as I2C,SPI)or analog output.Its compact design,high sensitivity and anti-interference ability make it suitable for harsh industrial environments.

Core Function

Three-axis synchronous measurement

Integrated X,Y,Z three-axis accelerometers can simultaneously measure vibration signals in three directions and comprehensively analyze equipment vibration characteristics(such as radial and axial vibrations).

Low cross-interference between axes(typical value<1%)ensures measurement independence.

Wideband response

Frequency range:0.5 Hz to 5 kHz(typical),covering low-frequency mechanical vibration(such as imbalance)to high-frequency fault characteristics(such as bearing defects).

Supports constant current(IEPE)or voltage output(some models),compatible with traditional vibration analyzers.

High accuracy and high sensitivity

Sensitivity:100 mV/g(typical, 1g acceleration),can detect small vibration changes.

Non-linearity:<0.1%FS(full scale),ensuring long-term measurement stability.

Resolution:up to 0.001g(depending on sampling rate and noise level),meeting the needs of precision diagnosis.

Anti-interference design

Protection level:IP67(dust and water proof),suitable for humid and dusty environments.

Temperature compensation:built-in temperature sensor,automatic correction of temperature drift(-40°C to+125°C operating range).

Electromagnetic compatibility(EMC):compliant with IEC 61000 standard,resistant to electromagnetic interference in industrial sites.

Flexible interface and power supply

Digital interface:supports I2C,SPI(some models),easy to integrate with embedded systems.

Analog output:0-5 V or 4-20 mA(optional),directly connected to PLC or DAQ devices.

Power supply:5-24 V DC wide voltage input,low power consumption design(typical value<10 mA).

Technical specifications

Parameter Specification

Measurement axis Three axes(X/Y/Z),orthogonal mounting

Frequency range 0.5 Hz to 5 kHz(±3 dB)

Sensitivity 100 mV/g(typical,customizable)

Range±2g/±5g/±10g(software configurable)

Non-linearity<0.1%FS

Resolution 0.001g(typical)

Output interface Digital:I2C/SPI;Analog:0-5 V/4-20 mA(optional)

Power supply 5-24 V DC

Operating temperature-40°C to+125°C(industrial grade)

Protection class IP67

Dimensions Compact design(e.g.30 mm×30 mm×15 mm,depending on model)

Weight<50 g(with cable)

Calibration Factory calibration,calibration certificate provided(some models support on-site self-calibration)

Application scenarios

Rotating machinery monitoring

Vibration analysis of equipment such as fans,pumps,compressors,etc.,to detect imbalance,misalignment,bearing failure,etc.

Structural health monitoring

Vibration modal analysis of bridges,buildings,and wind turbine blades to evaluate structural integrity.

Rail transportation

Train axle box and gear box vibration monitoring to prevent derailment or transmission system failure.

Energy industry

Turbine and generator vibration monitoring to optimize operation and maintenance cycles and reduce unplanned downtime.

Automotive testing

Engine and transmission system vibration testing to verify NVH(noise,vibration and harshness)performance.