描述

WAGO VDE0611是一款专为工业自动化系统设计的接地端子模块,符合VDE标准,主要用于优化接地系统设计,提升系统抗干扰能力和稳定性。以下是其核心功能与技术特点的综合解析:

一、核心功能与设计

标准化接地架构

VDE0611采用中心接地点设计,通过总母线(截面≥60mm²铜排)与接地极连接,接地电阻要求小于2Ω。接地极建议埋设于距建筑物10-15m外或与控制器保持50m以内,且需与强电设备接地点保持10m以上距离,以避免干扰耦合。

信号屏蔽处理

屏蔽层接地原则:信号源接地时,屏蔽层在信号侧接地;信号源不接地时,屏蔽层在PLC侧接地。

中间接头处理:信号线中间有接头时,需确保屏蔽层牢固连接并绝缘处理,避免接地环路干扰。

二、技术参数与性能

接地线规格:采用截面≥22mm²的铜导线,满足大电流回流需求。

兼容性:支持与多种工业设备(如变频器、PLC、传感器)协同工作,适用于钢铁、电力、石化等复杂工业环境。

三、应用场景与优势

干扰抑制

电源干扰防护:通过优化变送器和仪表供电电源的隔离措施(如选择分布电容小、漏感技术的配电器),减少共模与差模干扰。

动力电缆辐射抑制:建议使用铜带铠装屏蔽电力电缆(如变频器馈电电缆),降低电磁干扰对信号线的影响。

系统可靠性提升

供电稳定性:推荐采用在线式UPS供电,确保电网中断时系统持续运行,同时利用UPS的干扰隔离性能增强系统抗干扰能力。

电缆布局规范:不同信号类型分层布线,避免动力电源与信号线平行敷设,减少串扰风险。

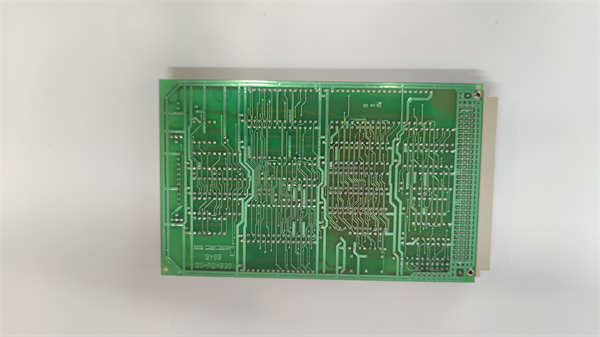

GESVDU-1D-8946

GESVDU-1D-8946

WAGO VDE0611 is a grounding terminal module designed for industrial automation systems.It complies with VDE standards and is mainly used to optimize the design of grounding systems and improve the system’s anti-interference ability and stability.The following is a comprehensive analysis of its core functions and technical features:

I.Core functions and design

Standardized grounding architecture

VDE0611 adopts a central grounding point design and is connected to the grounding electrode through a main busbar(copper bar with a cross-section of≥60mm²).The grounding resistance is required to be less than 2Ω.It is recommended that the grounding electrode be buried 10-15m away from the building or within 50m from the controller,and it must be kept more than 10m away from the grounding point of the high-voltage equipment to avoid interference coupling.

Signal shielding processing

Shielding layer grounding principle:When the signal source is grounded,the shielding layer is grounded on the signal side;when the signal source is not grounded,the shielding layer is grounded on the PLC side.

Intermediate joint processing:When there is a joint in the middle of the signal line,it is necessary to ensure that the shielding layer is firmly connected and insulated to avoid ground loop interference.

2.Technical parameters and performance

Grounding wire specifications:copper wire with a cross-section of≥22mm²is used to meet the needs of large current return.

Compatibility:supports working with a variety of industrial equipment(such as inverters,PLCs,sensors),and is suitable for complex industrial environments such as steel,electricity,and petrochemicals.

3.Application scenarios and advantages

Interference suppression

Power supply interference protection:By optimizing the isolation measures of the transmitter and instrument power supply(such as selecting a distributor with small distributed capacitance and leakage inductance technology),common mode and differential mode interference are reduced.

Power cable radiation suppression:It is recommended to use copper tape armored shielded power cables(such as inverter feeder cables)to reduce the impact of electromagnetic interference on signal lines.

System reliability improvement

Power supply stability:It is recommended to use online UPS power supply to ensure continuous operation of the system when the power grid is interrupted,and at the same time use the interference isolation performance of UPS to enhance the system’s anti-interference ability.

Cable layout specifications:Layered wiring of different signal types to avoid parallel laying of power supply and signal lines to reduce the risk of crosstalk.