描述

WATLOW ANAFAZE CLS216是一款高性能温度控制器,专为工业自动化和过程控制设计,以高精度、灵活性和可靠性为核心特点。以下是其产品简介:

1.产品概述

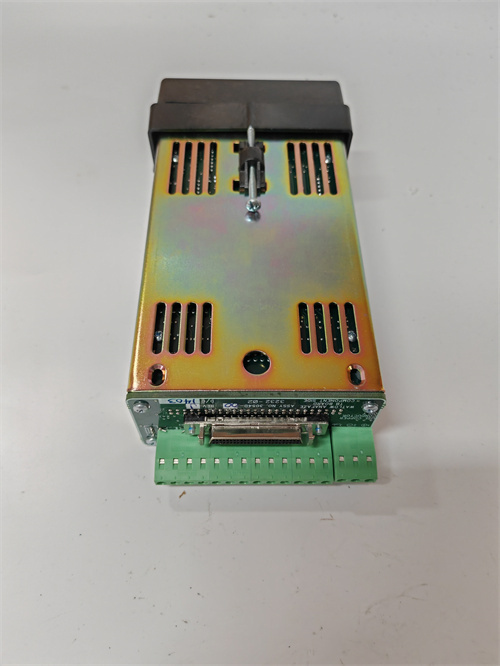

CLS216属于WATLOW ANAFAZE系列控制器,提供4、8或16回路版本,适用于加热、冷却及复杂温度控制场景。其紧凑型设计和模块化结构使其适用于空间受限的工业环境,同时支持独立运行或与PLC、SCADA系统集成。

2.核心功能

多回路控制:

最多支持16个独立回路的PID控制,每个回路可配置加热或冷却模式,减少面板空间并缩短安装时间。

传感器兼容性:

支持热电偶、RTD、线性电压/电流信号及频率输入,可通过菜单引导快速配置传感器类型,降低学习成本。

通信接口:

集成EIA/TIA-232和485通信协议,支持Modbus RTU协议,方便与PLC、上位机及第三方软件集成。

自动调谐功能:

通过动态分析过程响应,自动优化PID参数(比例带、积分时间、微分时间),缩短调试时间并提升控制精度。

报警与诊断:

提供高/低过程值、偏差报警及传感器故障检测(如短路、开路),支持34个数字输出用于控制或警报触发。

3.技术特点

高精度与响应速度:

部分型号支持±0.25%FS精度和<2ms响应时间,适用于快速变化的工业环境。

容错与可靠性:

支持冗余设计(如双模块容错架构),通过时间同步(UTC)、事件序列(SOE)等功能提升系统稳定性。

可编程性:

支持斜坡/浸泡功能、过程变量转发及远程设定点配置,满足复杂工艺需求。

用户界面:

配备全文字显示菜单和触摸键盘,支持本地操作或计算机远程监控,界面友好且操作简便。

4.应用领域

工业加热与制冷:

控制热压机、热处理设备等,确保温度稳定。

食品与制药:

监控烘烤、灭菌过程,符合卫生标准。

医疗设备:

用于培养箱、手术设备的恒温控制。

能源与汽车制造:

焊接、喷涂烘干等工艺的温度管理。

实验室与环境控制:

提供精确的实验环境或建筑温控解决方案。

WATLOW ANAFAZE CLS216 is a high-performance temperature controller designed for industrial automation and process control,with high precision,flexibility and reliability as its core features.The following is a product introduction:

1.Product Overview

CLS216 belongs to the WATLOW ANAFAZE series controller,available in 4,8 or 16 loop versions,suitable for heating,cooling and complex temperature control scenarios.Its compact design and modular structure make it suitable for space-constrained industrial environments,while supporting independent operation or integration with PLC and SCADA systems.

2.Core functions

Multi-loop control:

Supports PID control of up to 16 independent loops,each loop can be configured with heating or cooling mode,reducing panel space and shortening installation time.

Sensor compatibility:

Supports thermocouples,RTDs,linear voltage/current signals and frequency inputs,and can quickly configure sensor types through menu guidance to reduce learning costs.

Communication interface:

Integrated EIA/TIA-232 and 485 communication protocols,supports Modbus RTU protocol,and is convenient for integration with PLC,host computer and third-party software.

Automatic tuning function:

Automatically optimize PID parameters(proportional band,integral time,differential time)by dynamically analyzing process response,shorten debugging time and improve control accuracy.

Alarm and diagnosis:

Provide high/low process value,deviation alarm and sensor fault detection(such as short circuit,open circuit),and support 34 digital outputs for control or alarm triggering.

3.Technical features

High accuracy and response speed:

Some models support±0.25%FS accuracy and<2ms response time,suitable for rapidly changing industrial environments.

Fault tolerance and reliability:

Support redundant design(such as dual module fault tolerance architecture),improve system stability through time synchronization(UTC),event sequence(SOE)and other functions.

Programmability:

Support ramp/immersion function,process variable forwarding and remote set point configuration to meet complex process requirements.

User interface:

Equipped with full text display menu and touch keyboard,support local operation or computer remote monitoring,friendly interface and easy operation.

4.Application areas

Industrial heating and cooling:

Control hot presses,heat treatment equipment,etc.to ensure temperature stability.

Food and pharmaceutical:

Monitor the baking and sterilization processes to meet hygiene standards.

Medical equipment:

Used for constant temperature control of incubators and surgical equipment.

Energy and automotive manufacturing:

Temperature management of processes such as welding,spray drying,etc.

Laboratory and environmental control:

Provide precise experimental environment or building temperature control solutions.