描述

一、产品概述

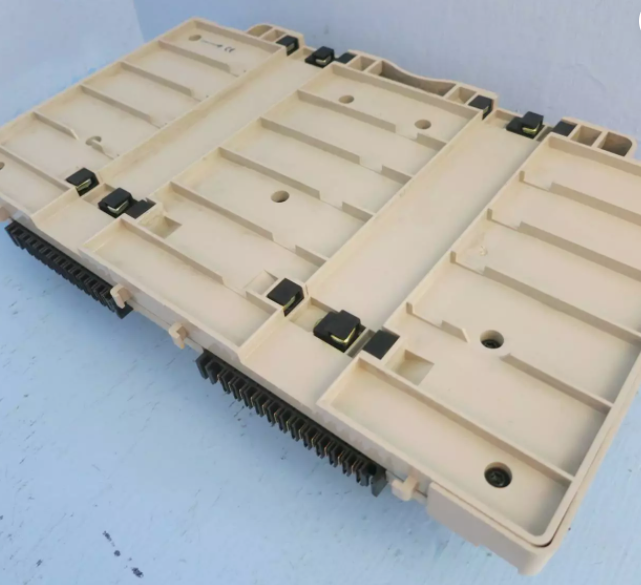

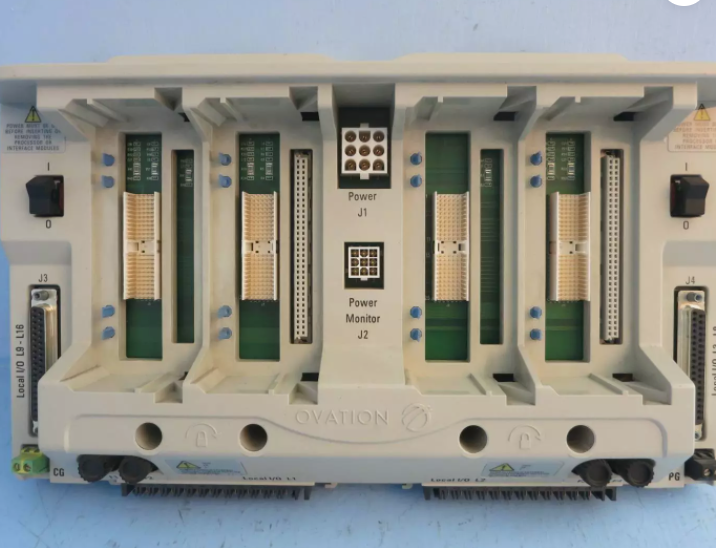

5X00225G01是西屋(Westinghouse)开发的分布式控制系统(DCS)模块,属于OVATION系列的核心组件,主要用于工业自动化领域的远程I/O控制与模拟信号输出。该模块由艾默生(Emerson)收购后沿用原型号,支持高精度模拟量输出(0-20mA)及多协议通信,适用于电力、化工、水处理等行业的过程控制场景。

二、核心功能与特点

模拟输出能力

支持0-20mA模拟信号输出,用于驱动执行机构(如阀门、电机)或连接传感器,实现精准控制。

内置光电耦合隔离设计,有效抑制电磁干扰,确保信号传输稳定。

通信与扩展性

硬PLC架构:采用MPC7457处理器,处理速度达1.267GHz,支持分布式控制与集中管理。

多协议兼容:集成Modbus通信协议,可与DeltaV、ABB、施耐德等主流控制系统无缝对接。

远程I/O支持:通过控制室安装方式实现远距离数据采集与指令下发。

高可靠性设计

环境适应性:工作温度范围-40°C至85°C,湿度5%-95%(非冷凝),适用于恶劣工业环境。

冗余与容错:支持主/备用控制器切换,故障时自动触发报警并记录事件日志。

状态监控与维护

LED指示灯:

电源(绿):模块供电正常。

通讯(绿):主/副控制网络状态正常。

故障(红):内部或外部异常(如电源中断、通信超时)。

日志记录:存储最近20次超速事件及50次感测行程,支持实时时钟同步。

三、技术参数

参数类别规格

结构形式模块式(控制室安装)

处理器MPC7457处理器,1.267GHz

内存容量512MB DDR内存+48MB数据存储

输出信号0-20mA模拟量输出

通信接口以太网、RS-232/RS-485(支持Modbus协议)

环境温度-40°C至85°C

防护等级IP56(需配合机柜安装)

重量2.5 kg

四、典型应用场景

工业过程控制

电力系统:控制发电机转速、电网负载分配及保护装置。

化工生产:调节反应釜温度、压力及流体流量。

能源管理

智能电网中的分布式能源监控与协调。

自动化生产线

机械臂运动控制、传感器信号采集与反馈。

1.Product Overview

5X00225G01 is a distributed control system(DCS)module developed by Westinghouse.It belongs to the core component of the OVATION series and is mainly used for remote I/O control and analog signal output in the field of industrial automation.After the acquisition by Emerson,this module is used as a prototype,and supports high-precision analog output(0-20mA)and multi-protocol communication.It is suitable for process control scenarios in the power,chemical,water treatment and other industries.

2.Core functions and features

Analog output capability

Supports 0-20mA analog signal output,used to drive actuators(such as valves,motors)or connect sensors to achieve precise control.

Built-in photoelectric coupling isolation design effectively suppresses electromagnetic interference and ensures stable signal transmission.

Communication and scalability

Hard PLC architecture:adopts MPC7457 processor,with a processing speed of 1.267GHz,supporting distributed control and centralized management.

Multi-protocol compatible:Integrated Modbus communication protocol,it can be seamlessly connected with mainstream control systems such as DeltaV,ABB,Schneider,etc.

Remote I/O support:realizes long-distance data acquisition and instruction issuance through the control room installation method.

High reliability design

Environmental adaptability:Operating temperature range-40°C to 85°C,humidity 5%-95%(non-condensing),suitable for harsh industrial environments.

Redundancy and fault tolerance:supports switching between main and standby controllers,and automatically triggers alarms and logs in event logs during failure.

Status monitoring and maintenance

LED indicator:

Power supply(green):The module is powered normally.

Communication(green):The main/sub-control network status is normal.

Fault(red):Internal or external abnormalities(such as power interruption,communication timeout).

Logging:Stores the last 20 speeding events and 50 sensing trips,and supports real-time clock synchronization.

3.Technical parameters

Parameter Category Specifications

Structural form Modular(control room installation)

Processor MPC7457 processor,1.267GHz

Memory capacity 512MB DDR memory+48MB data storage

Output signal 0-20mA analog output

Communication interface Ethernet,RS-232/RS-485(supports Modbus protocol)

Ambient temperature-40°C to 85°C

Protection level IP56(need to be installed with the cabinet)

Weight 2.5 kg

4.Typical application scenarios

Industrial process control

Power system:Control generator speed,grid load distribution and protection device.

Chemical production:Adjust the temperature,pressure and fluid flow rate of the reactor.

Energy Management

Distributed energy monitoring and coordination in smart grids.

Automated production line

Robotic arm motion control,sensor signal acquisition and feedback.