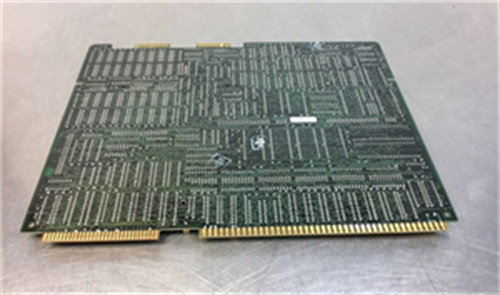

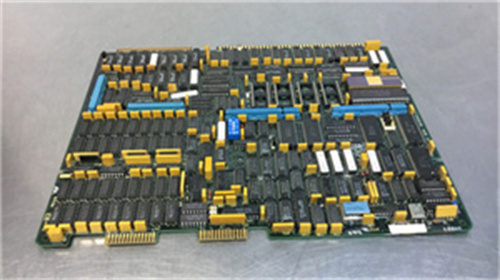

描述

WESTINGHOUSE 772B388G01是西屋电气(Westinghouse)为工业自动化系统设计的智能I/O模块,属于Ovation系列的核心扩展组件。以下是其产品特性与技术细节:

1.产品定位

该模块专为复杂工业场景设计,支持模拟量输入与数字量输入/输出的混合配置,可作为主控制器(如FlexLogix处理器)的扩展单元,实现分布式数据采集与控制。

2.核心功能与技术参数

通道类型与数量:

模拟量输入:支持8通道高精度电流/电压信号(如4-20mA、0-10V),采样精度±0.1%FS,适用于温度、压力等传感器信号。

数字量输入/输出:提供16通道光隔离数字量接口,支持干接点或电压信号输入,抗干扰能力强。

通信协议:

ControlNet:通过模块内置通信接口,支持与FlexLogix处理器或其他Ovation模块无缝连接,实现高速数据传输(速率10Mbps)。

RS-232/485:可选配通信卡扩展Modbus RTU等协议,兼容第三方设备。

防护与环境适应性:

工业级设计,防护等级IP30,工作温度范围-20°C至70°C,支持宽温版本(-40°C至85°C)。

电磁兼容性(EMC)符合IEC 61000标准,抗干扰能力突出。

3.应用场景

石油化工:监测反应釜压力、液位,配合主控制器实现安全联锁。

电力能源:采集发电机温度、转速数据,支持远程监控与故障诊断。

智能制造:集成工业机器人传感器信号,优化产线协同控制。

市政工程:污水厂流量计数据采集、阀门状态监控。

4.技术优势

模块化扩展:支持热插拔更换,单机柜最大扩展至数千点I/O,降低系统冗余成本。

自诊断功能:实时检测通道状态(如短路、断线),通过LED指示灯或通信接口反馈异常信息,缩短停机时间。

灵活配置:通过编程软件(如RSLogix 5000)设置信号类型、滤波参数及报警阈值,适应不同工艺需求。

5.兼容性与认证

系统兼容:与Ovation系列主控制器(如1C31127G01处理器)及扩展模块(如772B388G02模拟量输出模块)协同工作,形成完整控制系统。

国际认证:通过UL、CSA、CE认证,符合IEC 61508安全标准,适用于危险区域(如Class I Div 2)。

6.扩展功能

时间同步:支持UTC时间同步,确保多模块协同操作的精确性。

数据记录:可配置事件序列(SOE)功能,记录关键操作时序,便于故障分析。

WESTINGHOUSE 772B388G01 is an intelligent I/O module designed by Westinghouse for industrial automation systems.It is a core expansion component of the Ovation series.The following are its product features and technical details:

1.Product positioning

This module is designed for complex industrial scenarios and supports mixed configuration of analog input and digital input/output.It can be used as an expansion unit of the main controller(such as FlexLogix processor)to achieve distributed data acquisition and control.

2.Core functions and technical parameters

Channel type and quantity:

Analog input:supports 8 channels of high-precision current/voltage signals(such as 4-20mA,0-10V),with a sampling accuracy of±0.1%FS,suitable for sensor signals such as temperature and pressure.

Digital input/output:provides 16-channel optically isolated digital interface,supports dry contact or voltage signal input,and has strong anti-interference ability.

Communication protocol:

ControlNet:Through the module’s built-in communication interface,it supports seamless connection with FlexLogix processors or other Ovation modules to achieve high-speed data transmission(rate 10Mbps).

RS-232/485:Optional communication card expansion Modbus RTU and other protocols,compatible with third-party devices.

Protection and environmental adaptability:

Industrial-grade design,protection level IP30,operating temperature range-20°C to 70°C,support wide temperature version(-40°C to 85°C).

Electromagnetic compatibility(EMC)complies with IEC 61000 standards,with outstanding anti-interference ability.

3.Application scenarios

Petrochemical:Monitor reactor pressure and liquid level,and cooperate with the main controller to achieve safety interlocking.

Electric power:Collect generator temperature and speed data,support remote monitoring and fault diagnosis.

Intelligent manufacturing:Integrate industrial robot sensor signals to optimize production line collaborative control.

Municipal engineering:Sewage plant flow meter data collection,valve status monitoring.

4.Technical advantages

Modular expansion:supports hot-swap replacement,single cabinet can be expanded to thousands of I/O points,reducing system redundancy costs.

Self-diagnosis function:real-time detection of channel status(such as short circuit,disconnection),feedback of abnormal information through LED indicator or communication interface,shortening downtime.

Flexible configuration:set signal type,filter parameters and alarm threshold through programming software(such as RSLogix 5000)to adapt to different process requirements.

5.Compatibility and certification

System compatibility:works with Ovation series main controllers(such as 1C31127G01 processor)and expansion modules(such as 772B388G02 analog output module)to form a complete control system.

International certification:UL,CSA,CE certified,in compliance with IEC 61508 safety standards,suitable for hazardous areas(such as Class I Div 2).

6.Extended functions

Time synchronization:supports UTC time synchronization to ensure the accuracy of multi-module collaborative operation.

Data logging:Configurable sequence of events(SOE)function to record key operation timing for easy fault analysis.