描述

Westinghouse NL-708是西屋电气(Westinghouse)为工业自动化系统设计的核心可编程逻辑控制器(PLC)模块,广泛应用于化工、电力、石油等对稳定性与实时性要求严苛的领域。以下是其核心功能与技术特性:

1.核心功能与技术参数

模块类型:

采用模块式设计,支持现场安装,兼容24V AC/DC输入电压,适用于开关量信号采集与控制指令输出。

处理器特性:

配备硬PLC(逻辑指令处理器),支持高精度逻辑运算与实时响应,适用于复杂工业场景的快速控制需求。

通信协议:

支持Modbus、ControlNet等工业协议,可无缝集成至西屋Ovation系统或第三方控制系统(如ABB、施耐德)。

2.技术优势

高可靠性:

采用工业级防护设计(IP30等级),工作温度范围-20°C至70°C,满足严苛环境需求。

通过CE、UL认证,符合IEC 61508安全标准。

兼容性:

支持与主流工控设备(如西门子PLC、ABB DCS)协同工作,适配DCS系统、机器人系统及伺服控制场景。

扩展性:

支持热插拔更换,可与西屋其他模块(如3469A49G02、371D266G01等)扩展形成分布式控制系统。

3.应用场景

化工行业:

监测反应釜温度报警、压力开关状态,实现安全联锁控制。

电力系统:

采集发电机转速、断路器位置信号,辅助故障诊断与保护逻辑。

石油领域:

支持油井远程监控、管道压力/流量控制。

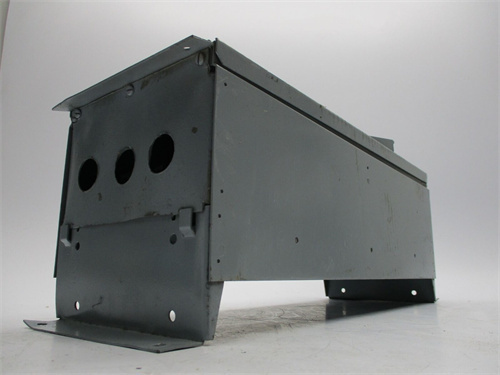

4.物理特性

尺寸与安装:标准模块化设计,支持导轨或壁挂安装,重量约2.5kg。

供电要求:24V AC/DC宽电压输入,增强适应性。

Westinghouse NL-708 is a core programmable logic controller(PLC)module designed by Westinghouse for industrial automation systems.It is widely used in chemical,electric power,petroleum and other fields with strict requirements on stability and real-time performance.The following are its core functions and technical features:

1.Core functions and technical parameters

Module type:

Adopts modular design,supports on-site installation,compatible with 24V AC/DC input voltage,suitable for switch signal acquisition and control command output.

Processor characteristics:

Equipped with hard PLC(logic instruction processor),supports high-precision logic operations and real-time response,suitable for rapid control requirements of complex industrial scenarios.

Communication protocol:

Supports industrial protocols such as Modbus and ControlNet,and can be seamlessly integrated into Westinghouse Ovation system or third-party control systems(such as ABB,Schneider).

2.Technical advantages

High reliability:

Adopts industrial-grade protection design(IP30 level),with an operating temperature range of-20°C to 70°C,meeting the needs of harsh environments.

CE and UL certified,compliant with IEC 61508 safety standards.

Compatibility:

Supports collaboration with mainstream industrial control equipment(such as Siemens PLC,ABB DCS),and is suitable for DCS systems,robot systems,and servo control scenarios.

Scalability:

Supports hot-swap replacement,and can be expanded with other Westinghouse modules(such as 3469A49G02,371D266G01,etc.)to form a distributed control system.

3.Application scenarios

Chemical industry:

Monitor reactor temperature alarm and pressure switch status to achieve safety interlock control.

Power system:

Collect generator speed and circuit breaker position signals to assist fault diagnosis and protection logic.

Petroleum field:

Supports remote monitoring of oil wells and pipeline pressure/flow control.

4.Physical characteristics

Size and installation:Standard modular design,supports rail or wall mounting,weighs about 2.5kg.

Power supply requirements:24V AC/DC wide voltage input,enhanced adaptability.