描述

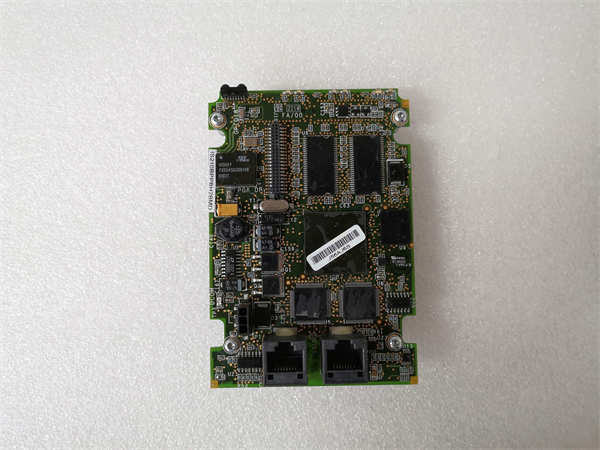

Woodhead SST-PB3-PCIE-2接口卡是一款专为工业自动化设计的高性能PCIe接口通信模块,支持多种工业协议,具备高可靠性与灵活性。以下是其核心功能与技术特点的综合概述:

一、核心功能与技术参数

协议支持

-Profibus DP/PA:兼容分布式I/O和过程自动化协议,可与多种工业设备通信。

-Profinet/Modbus TCP:支持工业以太网协议,实现与控制系统及自动化设备的高效数据交换。

传输速率与性能

-PCIe 3.0 x4接口:提供高速数据传输能力,支持高负载下的稳定通信。

-波特率范围:9.6 Kbaud至12 Mbaud,适应不同工业场景需求。

工业级可靠性

-宽温工作:支持0°C至60°C温度范围,适应复杂工业环境。

-抗干扰设计:通过工业级认证,具备抗电磁干扰(EMI)能力。

-诊断功能:内置LED指示灯,实时监控系统状态、看门狗超时及通信故障。

灵活性与兼容性

-多主站/从站配置:支持单主站或多主站模式,适配复杂分布式控制系统。

-操作系统兼容性:兼容Windows、Linux等主流平台,支持主流工业软件集成。

二、典型应用场景

工业自动化与过程控制

-连接PLC、DCS系统,实现设备监控与数据采集。

-应用于机器人控制、电气控制柜及驱动系统。

数据采集与分析

-支持实时数据交换,适用于生产线数据监测与分析。

分布式控制系统(DCS)

-在高精度控制场景中,如冶金、化工行业的过程自动化。

三、设计优势

模块化设计:易于安装与扩展,缩短系统部署时间。

即插即用:简化配置流程,降低维护成本。

长寿命:工业级元器件确保长期稳定运行。

IS200EPMCH1

IS200EPMCH1

The Woodhead SST-PB3-PCIE-2 interface card is a high-performance PCIe interface communication module designed for industrial automation.It supports a variety of industrial protocols and has high reliability and flexibility.The following is a comprehensive overview of its core functions and technical features:

I.Core functions and technical parameters

Protocol support

-Profibus DP/PA:Compatible with distributed I/O and process automation protocols,it can communicate with a variety of industrial equipment.

-Profinet/Modbus TCP:Supports industrial Ethernet protocols to achieve efficient data exchange with control systems and automation equipment.

Transmission rate and performance

-PCIe 3.0 x4 interface:Provides high-speed data transmission capabilities and supports stable communication under high load.

-Baud rate range:9.6 Kbaud to 12 Mbaud,adapting to different industrial scenarios.

Industrial reliability

-Wide temperature operation:Supports a temperature range of 0°C to 60°C to adapt to complex industrial environments.

-Anti-interference design:Passed industrial-grade certification and has anti-electromagnetic interference(EMI)capabilities.

-Diagnostic function:built-in LED indicator,real-time monitoring of system status,watchdog timeout and communication failure.

Flexibility and compatibility

-Multi-master/slave configuration:supports single master or multi-master mode,adapting to complex distributed control systems.

-Operating system compatibility:compatible with mainstream platforms such as Windows and Linux,supporting mainstream industrial software integration.

II.Typical application scenarios

Industrial automation and process control

-Connect PLC and DCS systems to achieve equipment monitoring and data acquisition.

-Applied to robot control,electrical control cabinets and drive systems.

Data acquisition and analysis

-Support real-time data exchange,suitable for production line data monitoring and analysis.

Distributed control system(DCS)

-In high-precision control scenarios,such as process automation in metallurgy and chemical industries.

III.Design advantages

Modular design:easy to install and expand,shortening system deployment time.

Plug and play:simplifies configuration process and reduces maintenance costs.

Long life:industrial-grade components ensure long-term stable operation.