描述

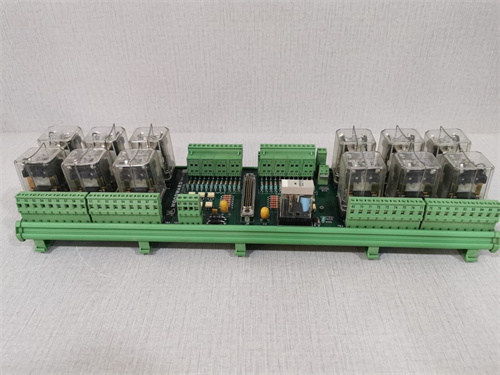

WOODWARD 5441-407是伍德沃德(Woodward)公司为工业自动化系统设计的状态继电器模块,主要用于可编程逻辑控制器(PLC)的步进顺控系统,通过与STL(步进顺控指令)配合,实现高效、易懂的程序逻辑控制。以下是其核心功能与技术特性:

1.核心功能与技术参数

状态继电器分类:

5441-407按功能分为五类,通过编号区分:

初始状态(S0-S9):系统启动时默认激活的初始步进状态。

回零状态(S10-S19):用于复位或故障处理的回零逻辑。

通用状态(S20-S499):用户自定义的通用控制状态,适用于复杂流程。

保持状态(S500-S899):需手动复位的状态,用于关键流程监控。

报警状态(S900-S999):触发异常时的报警逻辑控制。

接口与通信:

支持与主流PLC(如三菱、西门子)的梯形图编程语言无缝对接,通过RS-232/RS-485接口实现数据通信。

2.技术优势

高可靠性:

采用工业级设计,防护等级IP30,抗电磁干扰能力符合IEC 61000标准,适用于冶金、石油天然气、化工等严苛环境。

灵活性与标准化:

通过编号系统实现模块化控制逻辑,用户可快速构建复杂流程,减少编程时间。

抗干扰性:

内置滤波电路与看门狗定时器,确保在工业现场稳定运行。

3.应用场景

工业自动化:

冶金行业:控制轧钢机、高炉设备的步进工艺流程。

能源领域:管理燃气轮机、压缩机的启动与停机状态逻辑。

化工生产:监控反应釜温度、压力等关键参数的顺控过程。

系统集成:

可与Woodward其他模块(如5464-552、8561-537)协同工作,形成分布式控制系统。

4.技术背景与扩展

PLC与单片机对比:

5441-407作为PLC的核心元件,其梯形图语言的解释程序效率高于传统单片机,且抗干扰性能更强,适合工业控制需求。

替代方案:

可替代传统继电器硬接线逻辑,降低系统复杂度并提升维护便捷性。

WOODWARD 5441-407 is a state relay module designed by Woodward for industrial automation systems.It is mainly used in the stepper control system of programmable logic controllers(PLCs).By cooperating with STL(stepper control instructions),it can achieve efficient and easy-to-understand program logic control.The following are its core functions and technical features:

1.Core functions and technical parameters

Classification of state relays:

5441-407 is divided into five categories according to function,distinguished by number:

Initial state(S0-S9):The initial stepper state activated by default when the system starts.

Return to zero state(S10-S19):Return to zero logic for reset or fault handling.

General state(S20-S499):User-defined general control state,suitable for complex processes.

Hold state(S500-S899):A state that requires manual reset,used for key process monitoring.

Alarm state(S900-S999):Alarm logic control when an abnormality is triggered.

Interface and communication:

Supports seamless connection with ladder diagram programming language of mainstream PLC(such as Mitsubishi,Siemens),and realizes data communication through RS-232/RS-485 interface.

2.Technical advantages

High reliability:

Adopting industrial-grade design,protection level IP30,anti-electromagnetic interference capability complies with IEC 61000 standard,suitable for harsh environments such as metallurgy,oil and gas,and chemical industry.

Flexibility and standardization:

Modular control logic is realized through numbering system,users can quickly build complex processes and reduce programming time.

Anti-interference:

Built-in filter circuit and watchdog timer to ensure stable operation in industrial sites.

3.Application scenarios

Industrial automation:

Metallurgical industry:Control the stepping process of rolling mills and blast furnace equipment.

Energy field:Manage the start and stop state logic of gas turbines and compressors.

Chemical production:Monitor the sequential control process of key parameters such as reactor temperature and pressure.

System integration:

It can work with other Woodward modules(such as 5464-552,8561-537)to form a distributed control system.

4.Technical background and expansion

PLC and MCU comparison:

As the core component of PLC,5441-407 has a higher interpreter efficiency of ladder diagram language than traditional MCU,and has stronger anti-interference performance,which is suitable for industrial control needs.

Alternative solution:

It can replace the traditional relay hard-wired logic,reduce system complexity and improve maintenance convenience.