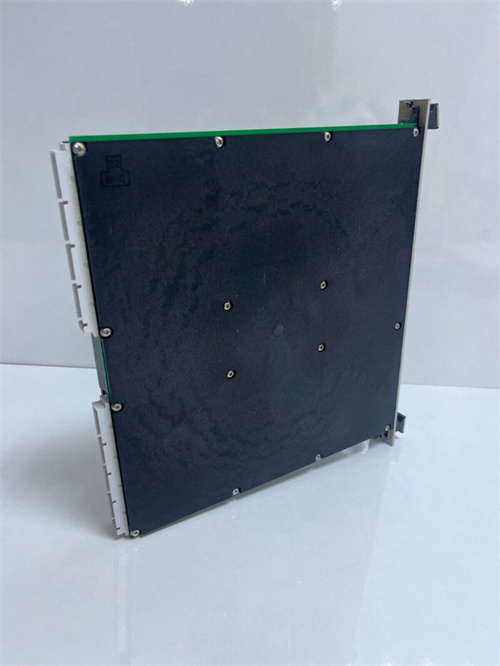

描述

WOODWARD 5461-082是伍德沃德(Woodward)公司为工业自动化系统设计的模块化I/O扩展模块,适用于可编程逻辑控制器(PLC)的分布式控制架构。以下是其核心功能与技术特性:

1.核心功能与技术参数

模块化设计:

采用积木式安装结构,支持自由组合CPU模块、数字量I/O模块、模拟量I/O模块、电源模块及通信模块,最多可扩展11个I/O模块。

I/O地址分配:

数字量输入模块:从左侧第一个模块开始,地址依次为IR000、IR001、IR002……

数字量输出模块:地址依次为IR100、IR101、IR102……

模拟量模块要求:

若使用模拟量I/O模块,需配置专用模拟量电源模块并紧邻安装,确保信号稳定传输。

通信接口:

支持RS-232/RS-485通信协议,可与主流PLC(如CQM1H系列)及上位机系统无缝对接。

2.技术优势

灵活性:

用户可根据实际需求选择模块类型及数量,适用于不同规模的工业控制系统。

抗干扰性:

通过模块化布局减少信号干扰,模拟量模块需独立供电以确保精度。

标准化:

遵循IEC 61131-3国际标准,支持梯形图(LAD)、功能块图(FBD)等编程语言。

3.应用场景

工业自动化:

作为PLC扩展模块,用于电机启停控制、传感器信号采集及执行器动作驱动。

能源管理:

在发电机组、燃气轮机等设备中,实现运行状态监测与安全联锁逻辑。

智能制造:

集成于工业机器人、自动化产线,管理物料输送、设备故障诊断等流程。

4.技术背景与扩展

替代传统方案:

相比继电器硬接线系统,模块化设计简化布线复杂度,降低维护成本。

协同工作能力:

可与Woodward其他模块(如5441-407状态继电器、5453-278工业交换机)配合,构建分布式控制系统。

WOODWARD 5461-082 is a modular I/O expansion module designed by Woodward for industrial automation systems.It is suitable for the distributed control architecture of programmable logic controllers(PLCs).The following are its core functions and technical features:

1.Core functions and technical parameters

Modular design:

Adopting a building block installation structure,it supports free combination of CPU modules,digital I/O modules,analog I/O modules,power modules and communication modules,and can expand up to 11 I/O modules.

I/O address allocation:

Digital input module:Starting from the first module on the left,the addresses are IR000,IR001,IR002…

Digital output module:The addresses are IR100,IR101,IR102…

Analog module requirements:

If analog I/O modules are used,a dedicated analog power module must be configured and installed close to ensure stable signal transmission.

Communication interface:

Supports RS-232/RS-485 communication protocols,and can be seamlessly connected with mainstream PLCs(such as CQM1H series)and host computer systems.

2.Technical advantages

Flexibility:

Users can choose the type and quantity of modules according to actual needs,which is suitable for industrial control systems of different sizes.

Anti-interference:

Reduce signal interference through modular layout,and analog modules need to be independently powered to ensure accuracy.

Standardization:

Follow the IEC 61131-3 international standard and support programming languagessuch as ladder diagram(LAD)and function block diagram(FBD).

3.Application scenarios

Industrial automation:

As a PLC expansion module,it is used for motor start and stop control,sensor signal acquisition and actuator action drive.

Energy management:

In generator sets,gas turbines and other equipment,it realizes operating status monitoring and safety interlocking logic.

Intelligent manufacturing:

Integrated in industrial robots and automated production lines to manage processes such as material transportation and equipment fault diagnosis.

4.Technical background and expansion

Replacement of traditional solutions:

Compared with the relay hard-wired system,the modular design simplifies wiring complexity and reduces maintenance costs.

Interoperability:

Can be used with other Woodward modules(such as 5441-407 status relay,5453-278 industrial switch)to build a distributed control system.