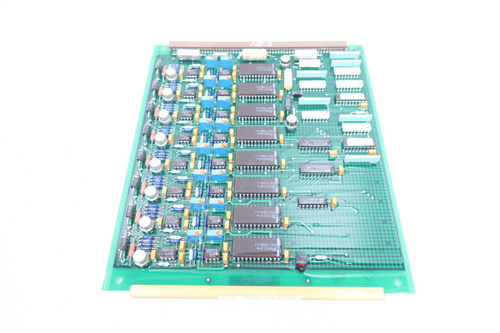

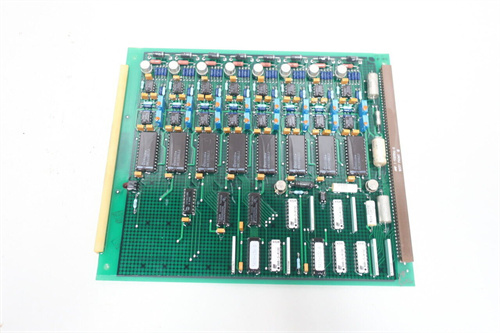

描述

WOODWARD 5461-644是伍德沃德(WOODWARD)公司推出的一款高性能伺服控制器,专为大型机械振动监测与故障诊断设计,广泛应用于工业自动化领域。以下是其核心功能与技术特性:

1.核心功能

实时数据采集与显示:支持准连续、高速、同步整周期采集设备振动信号,并动态显示设备运行状态,满足多场景监测需求。

灵活组态软件:提供可自定义的组态工具,用户可自由组合实时监测画面,提升工作效率。

智能状态识别:自动识别设备正常运行、开停机状态,并形成完备数据库,支持事故追忆功能。

频域分析与故障诊断:集成频谱、瀑布图、倒频谱、包络谱、细化谱、相位图、小波变换等分析工具,结合完善的诊断系统实现设备健康评估。

动平衡计算:支持多种动平衡算法,优化设备性能并延长使用寿命。

2.技术特点

网络化设计:采用TCP/IP协议与Winsock编程技术,提供远程监测与故障诊断接口,支持快速、安全的网络通信。

高可靠性:硬件采用模块化结构,便于维护与扩展,适配严苛工业环境。

兼容性:可与伍德沃德2301系列、500系列或NetCon控制器配套使用,形成完整控制系统。

3.应用领域

能源与动力设备:监测燃气轮机、柴油机等大型旋转机械振动,预防故障并优化运行效率。

工业自动化:集成于PLC/DCS系统,实现设备状态实时监控与智能维护。

轨道交通:应用于列车轴承、齿轮箱等部件的振动分析,保障运行安全。

4.技术背景

该产品基于伍德沃德在工业自动化领域的深厚积累,结合振动分析与伺服控制技术,旨在为客户提供从数据采集到故障诊断的全流程解决方案,提升设备可靠性与智能化水平。

WOODWARD 5461-644 is a high-performance servo controller launched by Woodward,designed for large-scale mechanical vibration monitoring and fault diagnosis,and widely used in the field of industrial automation.The following are its core functions and technical features:

1.Core functions

Real-time data acquisition and display:supports quasi-continuous,high-speed,and synchronous full-cycle acquisition of equipment vibration signals,and dynamically displays the equipment operation status to meet the monitoring needs of multiple scenarios.

Flexible configuration software:provides customizable configuration tools,and users can freely combine real-time monitoring screens to improve work efficiency.

Intelligent state recognition:automatically identifies the normal operation and start-up and shutdown status of the equipment,and forms a complete database to support accident recall function.

Frequency domain analysis and fault diagnosis:integrates analysis tools such as spectrum,waterfall diagram,inverse spectrum,envelope spectrum,refinement spectrum,phase diagram,wavelet transform,etc.,combined with a complete diagnostic system to achieve equipment health assessment.

Dynamic balancing calculation:supports a variety of dynamic balancing algorithms to optimize equipment performance and extend service life.

2.Technical features

Network design:Using TCP/IP protocol and Winsock programming technology,it provides remote monitoring and fault diagnosis interface,and supports fast and secure network communication.

High reliability:The hardware adopts a modular structure,which is easy to maintain and expand,and is suitable for harsh industrial environments.

Compatibility:It can be used with Woodward 2301 series,500 series or NetCon controllers to form a complete control system.

3.Application areas

Energy and power equipment:Monitor the vibration of large rotating machinery such as gas turbines and diesel engines,prevent failures and optimize operating efficiency.

Industrial automation:Integrated in PLC/DCS system to achieve real-time monitoring and intelligent maintenance of equipment status.

Railway transportation:Applied to vibration analysis of train bearings,gearboxes and other components to ensure safe operation.

4.Technical background

Based on Woodward’s deep accumulation in the field of industrial automation,combined with vibration analysis and servo control technology,this product aims to provide customers with a full-process solution from data acquisition to fault diagnosis,and improve the reliability and intelligence level of equipment.