描述

WOODWARD 5464-348是伍德沃德(WOODWARD)公司为工业自动化系统设计的核心控制模块,集成了控制器、执行器与调速器功能,广泛应用于发电机组、船舶设备及过程工业等领域。以下是其核心功能与技术特性:

1.核心功能

过程控制与调速:

作为控制器核心,实时处理传感器信号(如转速、压力、温度),通过PID算法调节执行器动作(如阀门开度、电机转速),实现精确的过程控制与调速功能。

故障诊断与保护:

集成电源、输入输出及工作状态诊断模块,支持以下故障排查流程:

电源异常:检查电压、熔丝及接线,替换电源部件或模块;

输入/输出失效:通过LED指示器区分模块或现场接线问题,替换故障模块或修复线路;

系统停机:触发软件卸载机制,强制执行器回位并断开断路器,保障设备安全。

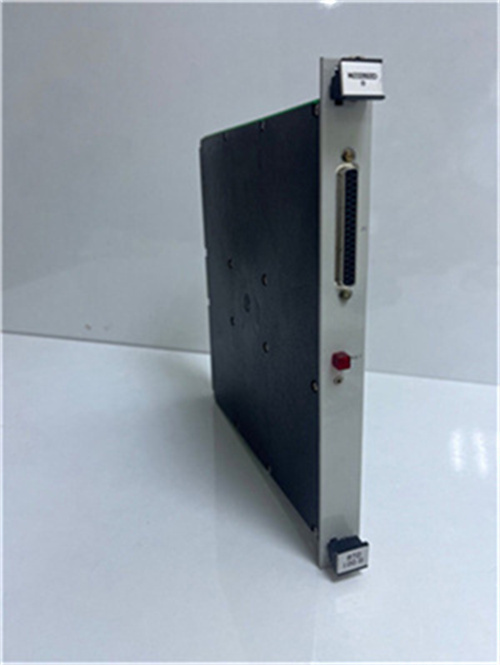

通信与扩展:

支持Modbus、Profibus等工业协议,可与上位机或DCS系统通信,兼容伍德沃德其他模块(如电源模块、I/O扩展模块)构建分布式控制系统。

2.技术参数与接口

输入输出:

数字输入:支持24V DC信号,用于接收传感器或PLC指令;

数字输出:驱动继电器或执行器,响应时间<20ms;

模拟输出:4-20mA信号可配置为同步示波器或过程变量输出。

电源与防护:

工作电压:24V DC或110V AC;

防护等级:IP30,宽温设计(-40℃至70℃),抗电磁干扰能力符合IEC 61000标准。

3.技术优势

高可靠性:

采用硬PLC架构(LD指令处理器),MTBF超过50,000小时,支持热插拔冗余配置,适用于不间断运行场景。

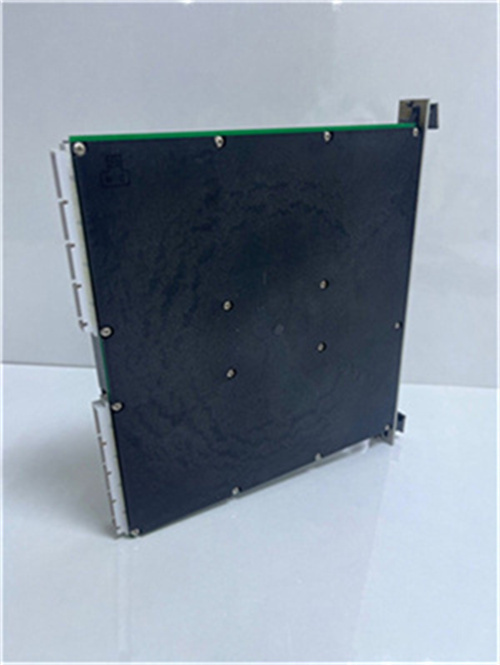

模块化设计:

可与伍德沃德5461系列控制器、500系列调速器等模块协同工作,灵活扩展功能。

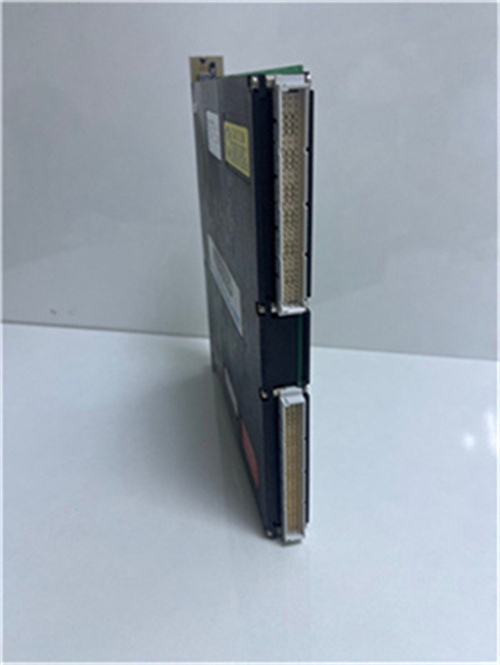

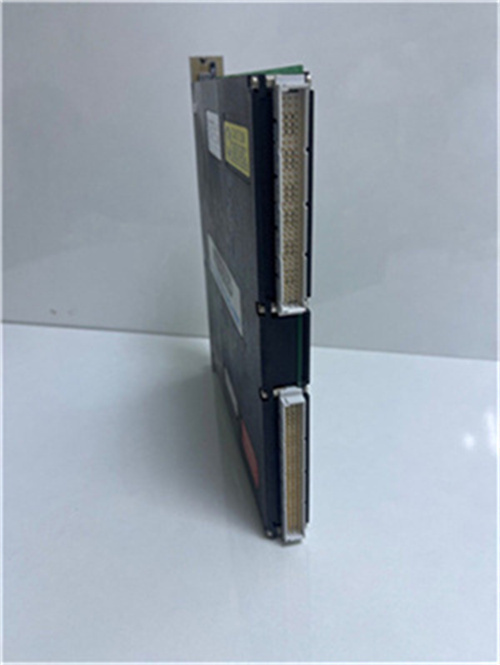

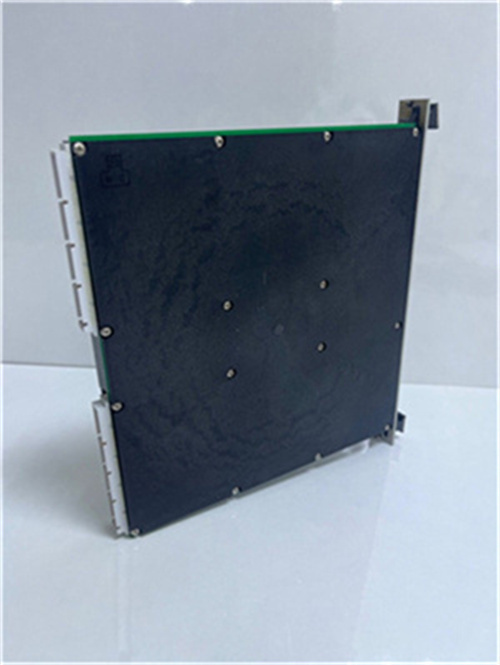

工业级防护:

金属外壳与密封设计,适应振动、潮湿等严苛工业环境。

4.应用场景

发电机组控制:

用于燃气轮机、柴油机的转速调节、负荷分配及并网控制。

船舶设备:

驱动推进系统执行器、舵机或液压阀,实现精准定位与动态响应。

过程工业:

控制化工、石油行业中的压力调节阀、流量计等设备,优化工艺流程。

WOODWARD 5464-348 is a core control module designed by Woodward for industrial automation systems.It integrates controller,actuator and speed regulator functions and is widely used in generator sets,marine equipment and process industries.The following are its core functions and technical features:

1.Core functions

Process control and speed regulation:

As the core of the controller,it processes sensor signals(such as speed,pressure,temperature)in real time,and adjusts the actuator action(such as valve opening,motor speed)through PID algorithm to achieve precise process control and speed regulation functions.

Fault diagnosis and protection:

Integrated power supply,input and output and working status diagnosis modules support the following troubleshooting processes:

Power supply abnormality:check voltage,fuse and wiring,replace power supply components or modules;

Input/output failure:distinguish module or field wiring problems through LED indicators,replace faulty modules or repair lines;

System shutdown:trigger software uninstall mechanism,force actuator to return and disconnect circuit breaker to ensure equipment safety.

Communication and expansion:

Supports industrial protocols such as Modbus and Profibus,can communicate with the host computer or DCS system,and is compatible with other Woodward modules(such as power modules,I/O expansion modules)to build distributed control systems.

2.Technical parameters and interfaces

Input and output:

Digital input:supports 24V DC signals for receiving sensor or PLC instructions;

Digital output:drives relays or actuators,response time<20ms;

Analog output:4-20mA signal can be configured as a synchronous oscilloscope or process variable output.

Power supply and protection:

Working voltage:24V DC or 110V AC;

Protection level:IP30,wide temperature design(-40℃to 70℃),anti-electromagnetic interference capability complies with IEC 61000 standards.

3.Technical advantages

High reliability:

Adopts hard PLC architecture(LD instruction processor),MTBF exceeds 50,000 hours,supports hot-swappable redundant configuration,and is suitable for uninterrupted operation scenarios.

Modular design:

Can work with Woodward 5461 series controller,500 series speed governor and other modules to flexibly expand functions.

Industrial protection:

Metal shell and sealing design,suitable for harsh industrial environments such as vibration and humidity.

4.Application scenarios

Generator control:

Used for speed regulation,load distribution and grid connection control of gas turbines and diesel engines.

Marine equipment:

Drive propulsion system actuators,steering gears or hydraulic valves to achieve precise positioning and dynamic response.

Process industry:

Control pressure regulating valves,flow meters and other equipment in the chemical and petroleum industries to optimize process flows.